5 - 20

5 Dedicated Options

MITSUBISHI CNC

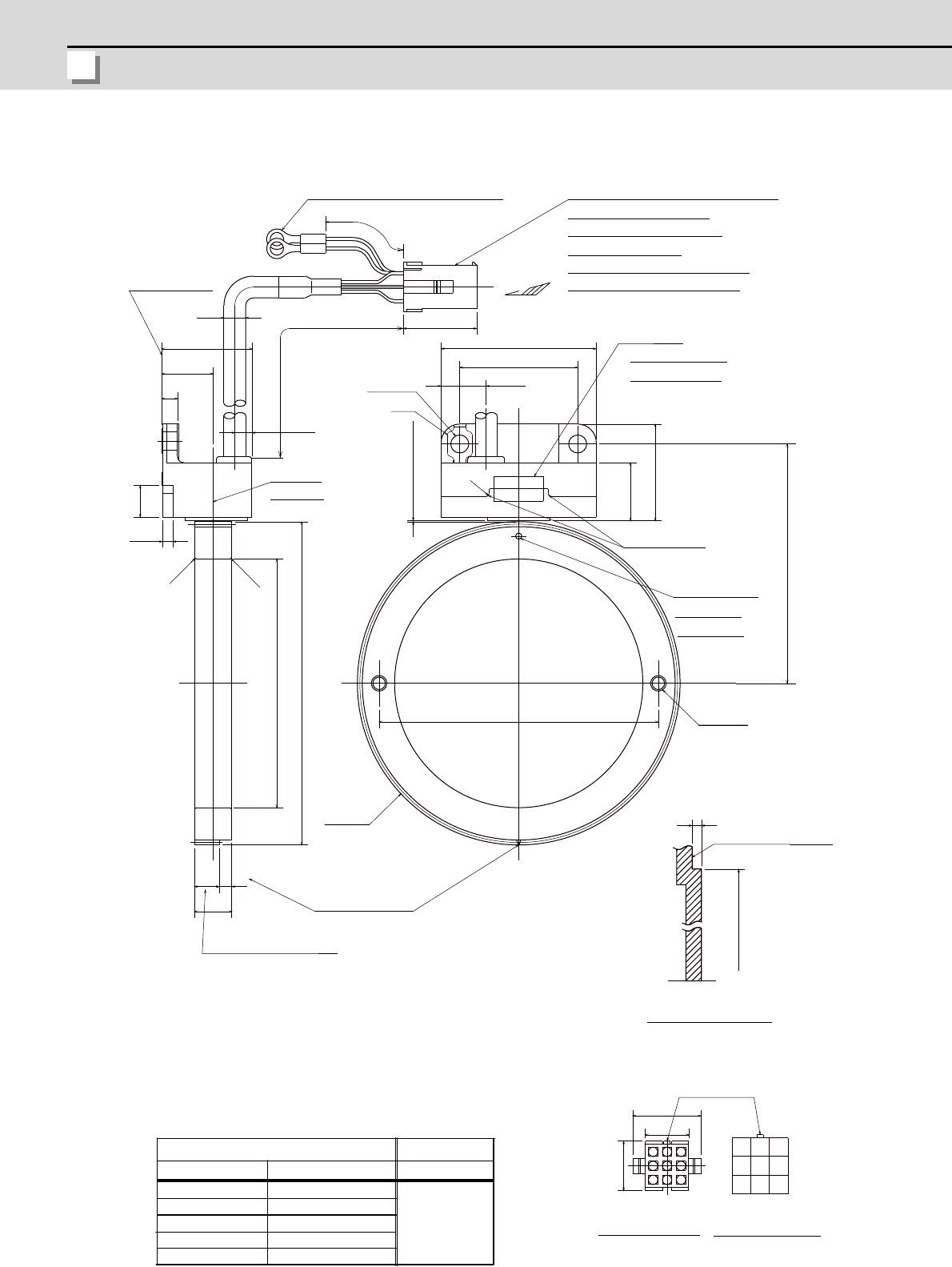

<TS5690N12xx + MU1606N709>

[Unit: mm]

RQ

MT1

987

456

321

MT2

RQ*

SDSD*

+5V

5G

FG

Ǿ122±0.025

16

22

3

48

12

Ǿ80H5

90

14

14.5

5.5

77

C0.5

C0.5

Ǿ7

29

A

23.7

100±10

A

5

R1

16.5

18.7

31.1

3.3

10.3

2-Ǿ5.8

38

50

0.3

±

0.05

MU1606N709

1200±20

1600±30

2000±30

TS5690N1220

TS5690N1230

TS5690N1240

TS5690N1260

TS5690N1210

800±20

400±10

Detection gear outer DIA Ǿ104

Round crimp contact for thermistor 0.5-4

(For M4 screw)

Output connector (by Tyco Electronics)

Housing (Cap) #172161-1

Contact (Socket) #170365-4

Accessories (Note 5)

Housing (Plug) #172169-1 Qty: 1

Contact (Pin) #170363-4 Qty: 9

Name plate

Sensor model and

Serial No. written

Ground

Gap

C part (Note 2)

D part (Note 3)

Ǿ2 hole for

identification

2-M5 screw

Sensor mounting face

Encoder mounting face

of machine side

Projection for

connector lock

Seen from Arrow A

Pin layout of output

connector

Sensor

Parts name

Lead wire length A

Detection gear

Parts name

The number of teeth 128

(For A, B phase signals)

One notch (For Z

phase signal)

Detection

gear

Central line of

detection gear

(Note 4)

Sensor mounting

face (Note 4)

(Note 1)

Handle with care as this is a precision component.

Pay special attention not to apply excessive external force

on the sensor’s detection face. Applying such force will cause a fault.

In installing the sensor, keep the protruding fitting of Ǿ122±0.025

on the machine side, and push the C part of the sensor mounting seat

against the fitting.

In installing the detection gear, make sure that the D part side comes

the opposite side of the sensor installation side (sensor’s lead wire side).

The diviation of the center of the detection gear is 16.5±0.25mm

from the sensor mounting face.

A connector of the signal cable side (one plug and nine pins) is attached.

(Note 2)

(Note 3)

(Note 4)

(Note 5)