(5) Troubleshooting

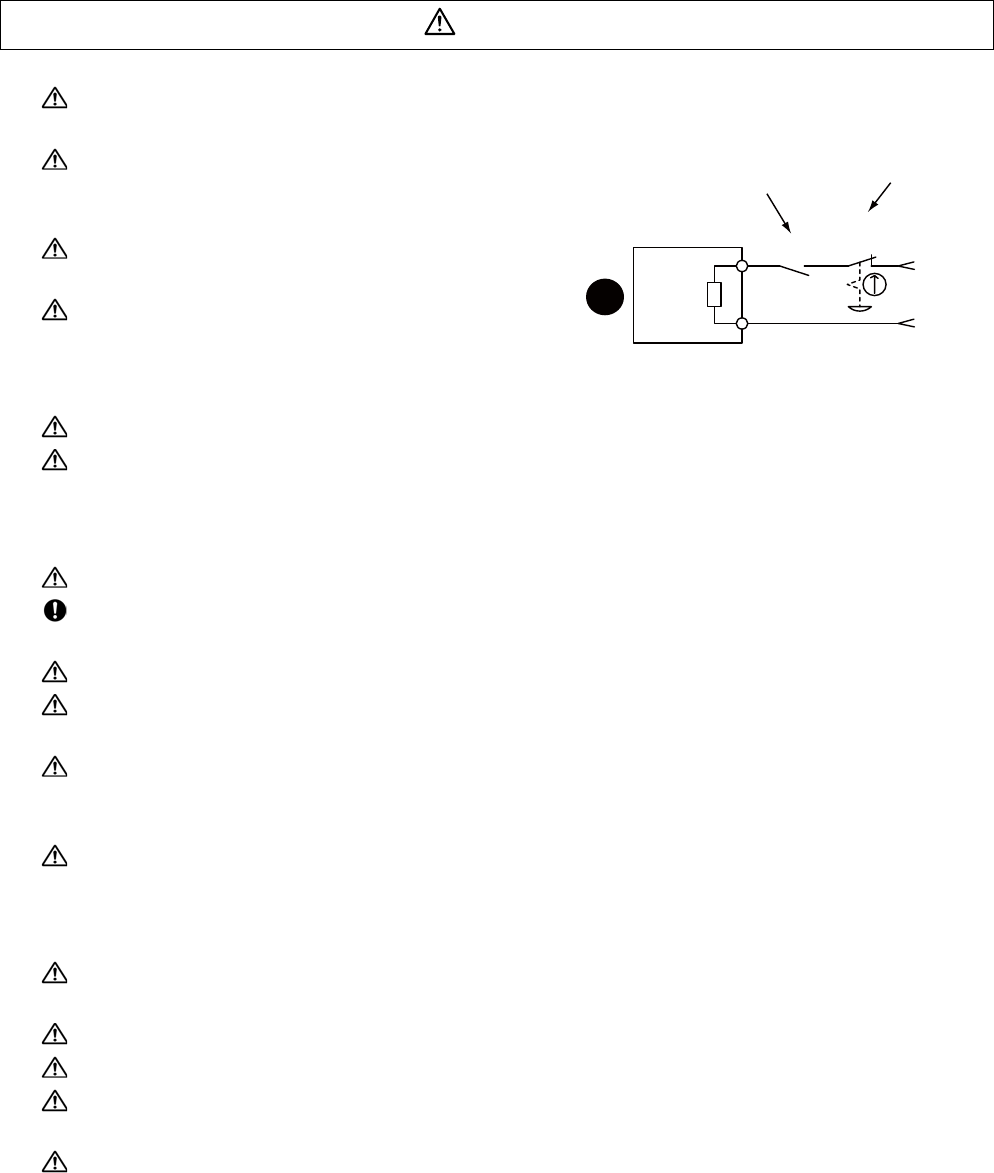

If a hazardous situation is predicted during power failure or product trouble, use a servomotor with

magnetic brakes or install an external brake mechanism.

Use a double circuit configuration that allows the

operation circuit for the magnetic brakes to be operated

even by the external emergency stop signal.

Always turn the main circuit power of the motor OFF

when an alarm occurs.

If an alarm occurs, remove the cause, and secure the

safety before resetting the alarm.

(6) Maintenance, inspection and part replacement

Always backup the programs and parameters before starting maintenance or inspections.

The capacity of the electrolytic capacitor will drop over time due to self-discharging, etc. To prevent

secondary disasters due to failures, replacing this part every five years when used under a normal

environment is recommended. Contact the Service Center, Service Station, Sales Office or delayer for

repairs or part replacement.

Do not perform a megger test (insulation resistance measurement) during inspections.

If the battery low warning is issued, back up the machining programs, tool data and parameters with an

input/output unit, and then replace the battery.

Do not short circuit, charge, overheat, incinerate or disassemble the battery.

For after-purchase servicing of the built-in motor (including the detector), supplies of servicing parts and

repairs can only be offered.

For maintenance, part replacement, and services in case of failures in the built-in motor (including the

detector), take necessary actions at your end. For spindle drive unit, Mitsubishi can offer the after-

purchase servicing as with the general spindle drive unit.

When a failure has occurred in the built-in motor (including the detector), some period of time can be

required to supply the servicing parts or repair. Prepare the spare parts at your end whenever possible.

(7) Disposal

Take the batteries and backlights for LCD, etc., off from the controller, drive unit and motor, and dispose

of them as general industrial wastes.

Do not disassemble the unit or motor.

Dispose of the battery according to local laws.

Always return the secondary side (magnet side) of the linear servomotor to the Service Center or

Service Station.

When incinerating optical communication cable, hydrogen fluoride gas or hydrogen chloride gas which

is corrosive and harmful may be generated. For disposal of optical communication cable, request for

specialized industrial waste disposal services that has incineration facility for disposing hydrogen

fluoride gas or hydrogen chloride gas.

CAUTION

MBR

EMG

Servomotor

Magnetic

brake

Shut off with the servomotor

brake control output.

Shut off with NC brake

control PLC output.

24VDC