7 - 8

7 Selection

MITSUBISHI CNC

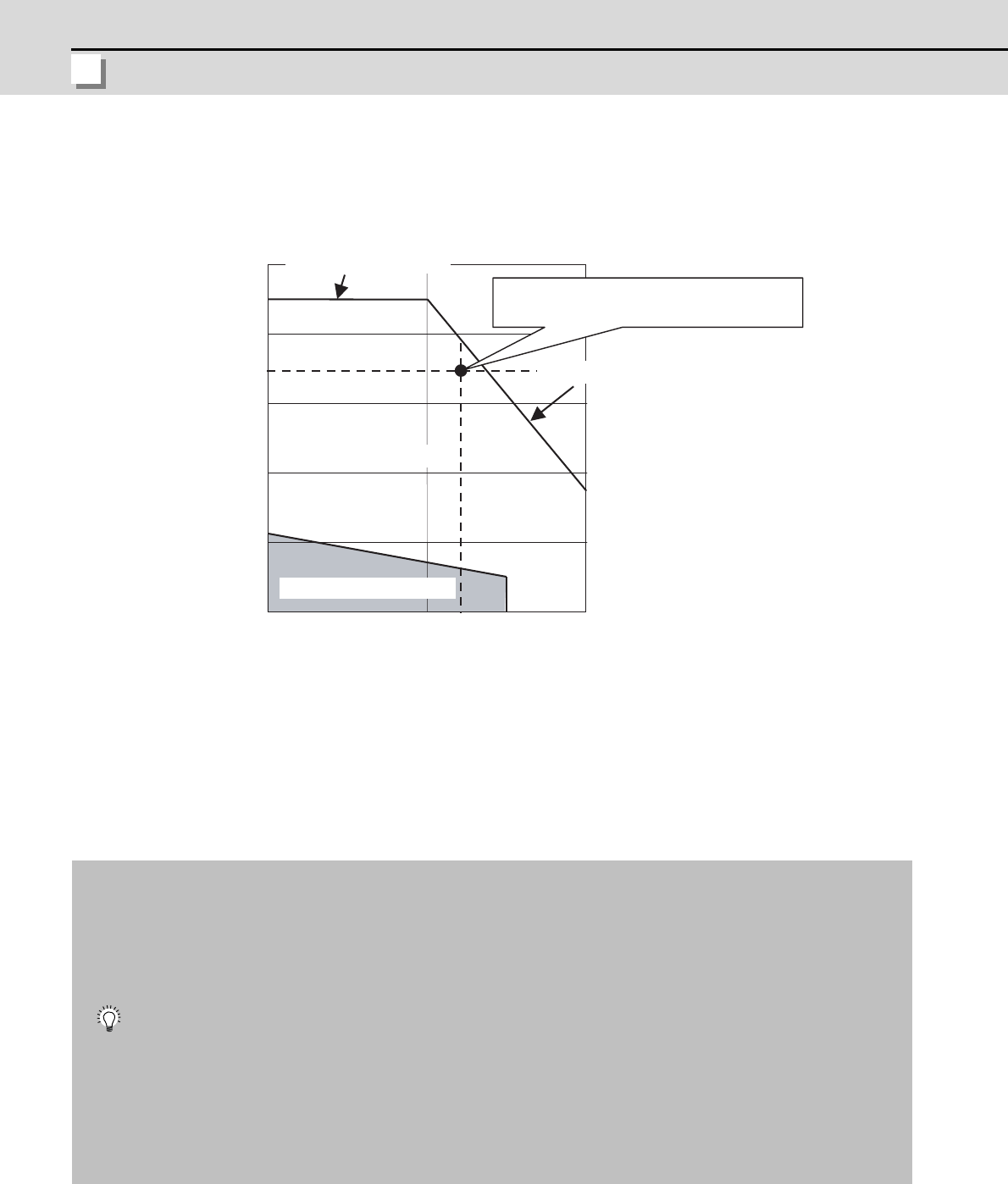

(e) Confirmation in the torque characteristics

Confirm whether the maximum torque "Ta1" and maximum torque occurrence speed "Nm" required for

this acceleration/deceleration pattern calculated in the item "(b)" to "(d)" are in the short time operation

range of the torque characteristics.

Motor torque characteristics

If they are not in the short time operation range, return to the item "(b)" to "(d)" and make the linear

acceleration/deceleration time constant "ta" large.

If the acceleration specification cannot be changed (the linear acceleration/deceleration time constant

cannot be increased), reconsider the selection, such as increasing the motor capacity.

1. In selecting the maximum torque "Ta1" required for this acceleration/deceleration pattern, the

measure of it is 80% of the motor maximum torque "T

MAX

"

2. In high-speed rotation range, confirm that the maximum torque "Ta1" and maximum torque

occurrence speed "Nm" required for this acceleration/deceleration is in the short time operation

range.

3. The drive system efficiency is normally approx. 0.95 in the ball screw mechanism and approx. 0.8

in the gear mechanism

4. For the torque characteristics in the motor high-speed rotation range, the AC input voltage is 200V.

If the input voltage is low or if the power wire connecting the servomotor and drive unit is long (20m

length), the short time operation range is limited. In this case, an allowance must be provided for

the selection of the high-speed rotation range.

0 2000 4000

0

20

40

100

80

60

Rotation speed [r/min]

Continuous operation range

Short time operation range

Required maximum torque: Ta1

Required maximum torque occurrence speed: Nm

Motor maximum torque

High-speed rotation range

torque characteristic

Torque [N m]

POINT