For Machines Mfg. Since 7/09 Model SB1016/SB1036

-27-

PREPARATION

14. Make sure that all bystanders are out of the

way, tools are cleared away, and the chuck

key is removed from the chuck.

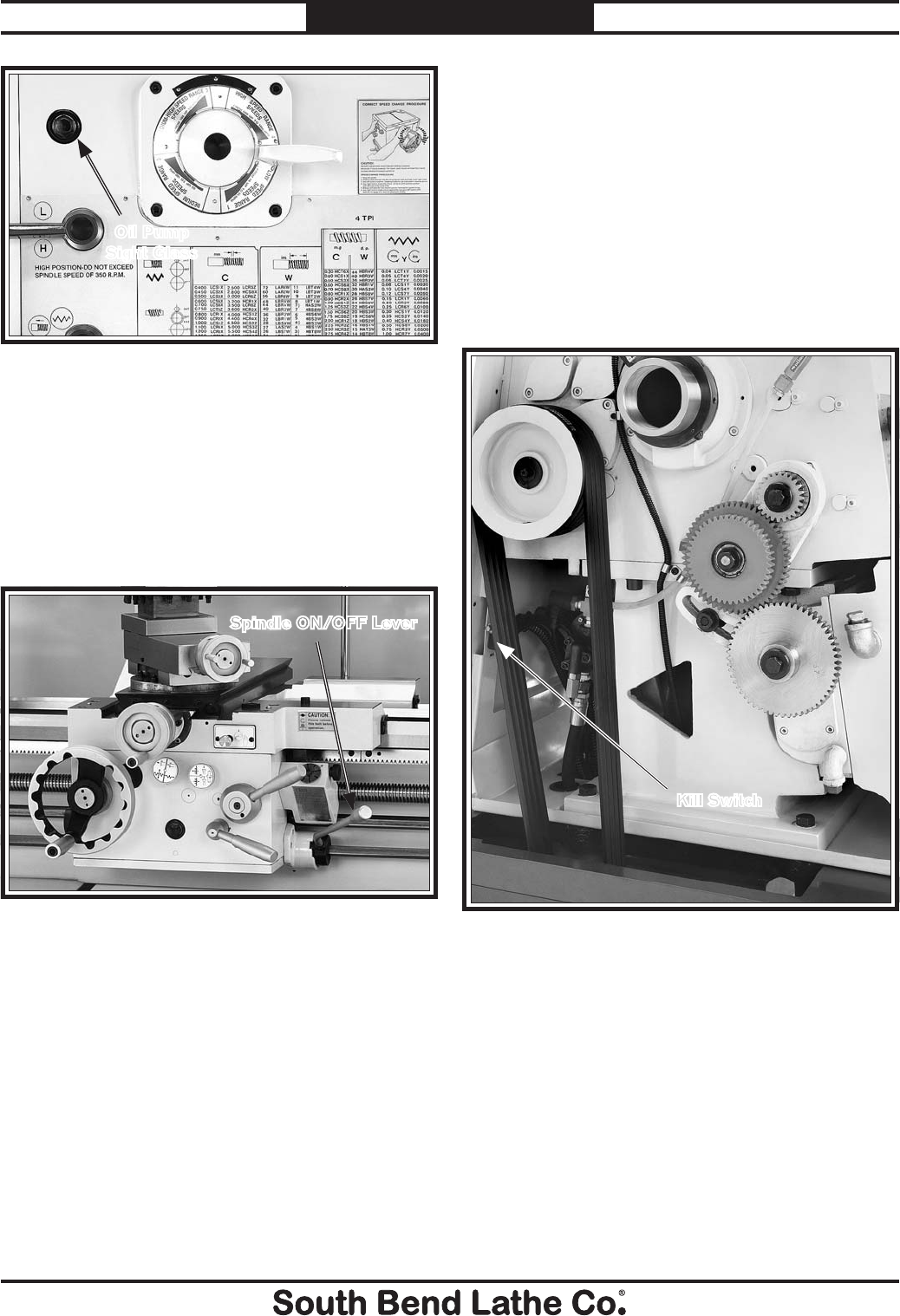

15. Move the spindle ON/OFF lever (Figure

26) down and the chuck will rotate counter-

clockwise (down and toward you, as you face

the front of the lathe).

Figure 25. Oil pump sight glass.

Oil Pump

Sight Glass

Figure 26. Starting the lathe.

16. Observe the lathe and listen for any

abnormal noises or vibration. The lathe

should run smoothly. If the spindle rotates in

the incorrect direction, refer to Correcting

Phase Polarity

on Page 16 to solve the

problem.

17. Push the stop button. The lathe should stop.

18. Move the spindle ON/OFF lever up to the

OFF position, reset the stop button by

twisting it clockwise until it pops out, then

restart the spindle with the lever.

19. Push the foot brake. The lathe should come

to a quick stop.

— If the foot brake has no effect on the lathe,

push the stop button, and refer to V-Belts

and Brake & Switch on Page 81 to

make any required adjustments.

20. Remove the lathe headstock side cover.

The kill switch shown in Figure 27 should

prevent the lathe from starting while this

cover is removed.

21. Stand away from all the exposed gears on

the side of the headstock, and attempt to

start the lathe.

— If the lathe starts, the safety switch is not

functioning properly and may need to be

replaced before the machine can be safely

operated.

22. Reinstall the end gear cover, then start the

lathe.

Figure 27. Headstock gear cover kill switch.

Kill Switch

Spindle ON/OFF Lever