-54-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

OPERATION

Power Feed Controls

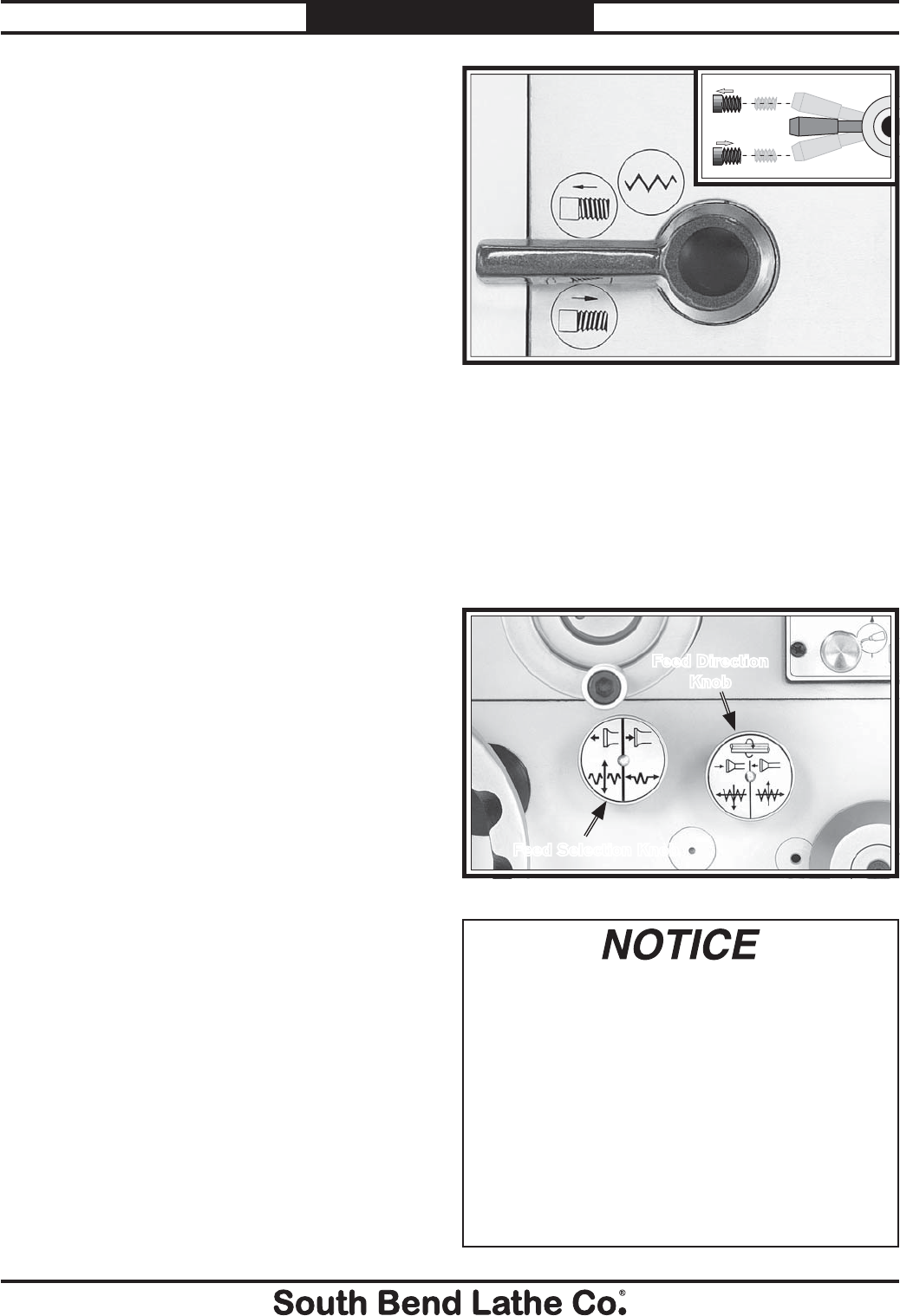

The headstock feed direction lever shown in

Figure 89 controls the direction the carriage

moves. However, it is important to understand

that there is a direction change relationship

between the headstock feed direction lever and

the apron feed direction knob (see Figure 90).

The apron feed direction knob and the headstock

feed direction lever reverse the feed direction of

each other. For example:

When the apron feed direction knob is s

pushed-in, the direction of carriage travel

shown on the headstock feed direction lever

plate is applicable only when threading. For

feeding, the directions shown will be opposite.

When the apron feed direction knob is pulled-s

out, the direction of carriage travel shown on

the headstock feed direction plate is accurate

only when feeding. For threading, the

directions shown will be opposite.

On this lathe, both the carriage and cross slide

have power feed capability. The power feed

system is protected by an adjustable feed rod

clutch located on the input side of the apron.

The rate that these components move (feed rate)

is controlled by how the quick change gearbox

levers are configured.

Feed rate and spindle speed must be considered

together. The sources you use to determine the

optimum spindle speed for an operation will also

provide the optimal feed rate to use with that

spindle speed. Often, the experienced machinist

will use the feeds and speeds given in their

reference charts or web calculators as a starting

point, then make minor adjustments to the feed

rate (and sometimes spindle speed) to achieve

the best results.

The carriage can also be driven by the leadscrew

for threading operations. However, this section

covers using the power feed option only for non-

threading operations. To learn how to power the

carriage for threading operations, refer to the

Threading Controls section Page 56.

Power Feed

Figure 89. Headstock feed direction lever.

FORWARD

REVERSE

NEUTRAL

The main benefit of the apron feed direction

knob shown in Figure 90 is that it changes the

direction of the selected feed without having

to stop the lathe, and walk over and shift the

headstock feed direction lever.

The feed selection knob shown in Figure 90

engages either the carriage or cross slide feed.

The apron feed direction knob and the

headstock feed direction lever reverse the

feed direction of each other. Before and after

power feed operations, push-in the apron

feed direction knob to the "normal position".

Otherwise, if it is left pulled out, another lathe

operator may move refer to the headstock

plate and select a feed direction selection

lever to his desired, only to suddenly realize

when feeding begins, the feed movement is

opposite what was shown causing possible

carriage crash!

Figure 90. Apron feed knobs.

Feed Selection Knob

Feed Direction

Knob