-52-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

OPERATION

Manual Feed

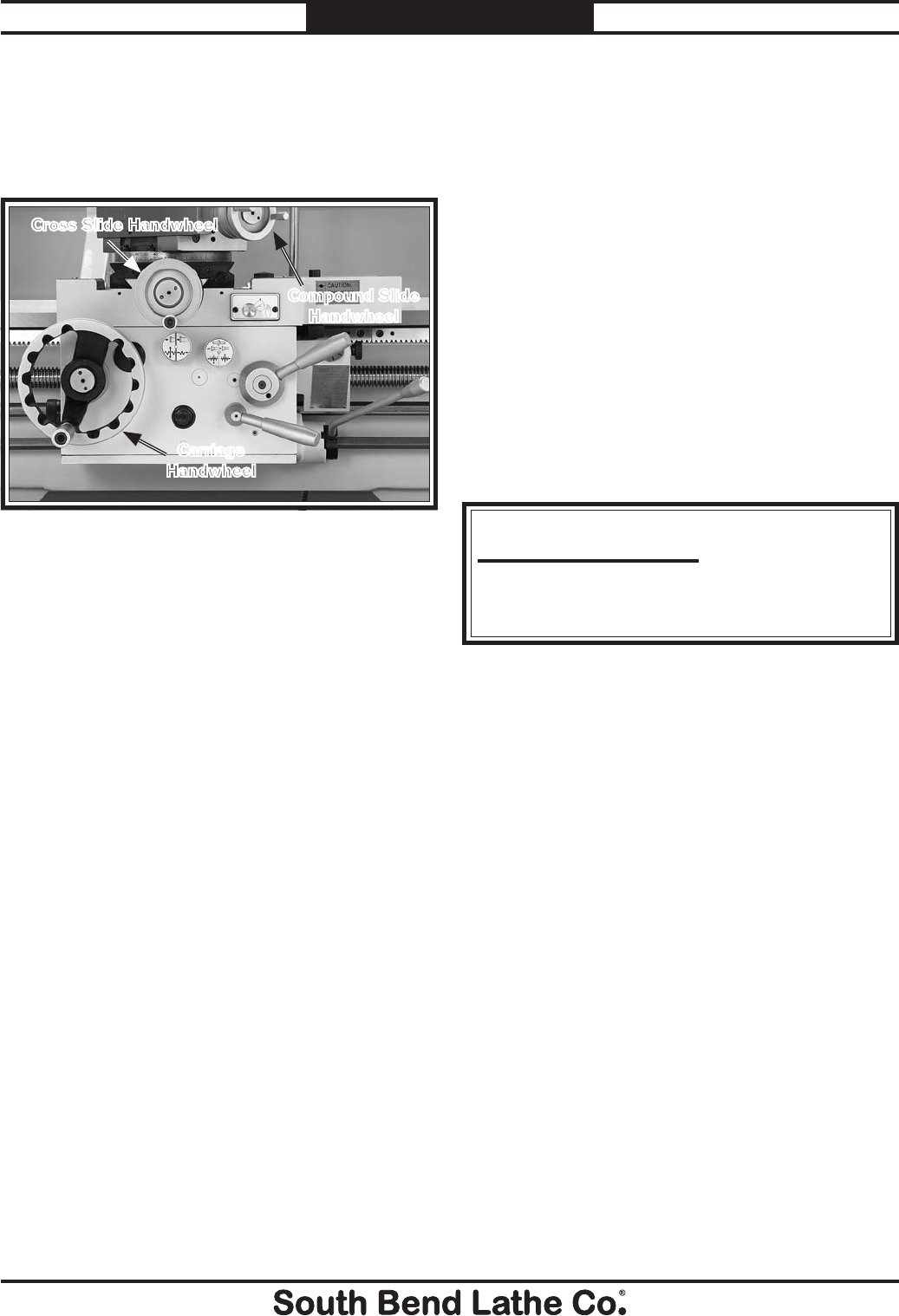

These three handwheels (see Figure 83)

manually position and control the cutting tool for

lathe operations.

Carriage Handwheel

Moves the carriage parallel along the ways,

and is equipped with a graduated collar in

increments of 0.010" where 360°= 0.990". The

handwheel can also be disengaged when power

feed operations would make it an entanglement

hazard by pushing it in.

Cross Slide Handwheel

Moves the cross slide perpendicular to the ways.

For every revolution of the handwheel, the slide

moves twice the distance or at a at a 1:2 ratio.

The graduated collar indicates in increments

of 0.001"where 360°= 0.200". When turning for

example the scale directly reads the resulting

workpiece diameter.

Compound Slide Handwheel

Moves the tool in fine increments into the

workpiece. The handwheel has an "indirect

reading" graduated collar that is broke down

in 0.001" increments. When the tool path is

perpendicular to the workpiece, the movement

that is shown on the scale is only half of what

has been removed from the workpiece. For

example, if the handwheel is rotated 0.001"

the compound slide and tool bit moves 0.001".

This results in 0.002: being removed from the

workpiece diameter.

Figure 83. Carriage handwheels.

Cross Slide Handwheel

Compound Slide

Handwheel

Carriage

Handwheel

Spindle Speed

Using the correct spindle speed is important

for safe and satisfactory results, as well as

maximizing tool life.

To set the spindle speed for your operation, you

will need to: (1) Determine the best spindle speed

for the cutting task, and (2) configure the lathe

controls to produce the required spindle speed.

Determining Spindle Speed

Many variables affect the optimum spindle speed

to use for any given operations, but the two most

important are the recommended cutting speed

for the workpiece material and the diameter of

the workpiece, as noted in the formula shown in

Figure 84:

Cutting speed, typically defined in feet per

minute (FPM), is the speed at which the edge of a

tool moves across the material surface.

A recommended cutting speed is an ideal speed

for cutting a type of material in order to produce

the desired finish and optimize tool life.

The books Machinery’s Handbook or Machine

Shop Practice, and some internet sites, provide

excellent recommendations for which cutting

speeds to use when calculating the spindle speed.

These sources also provide a wealth of additional

information about the variables that affect

cutting speed and they are a good educational

resource.

Also, there are a large number of easy-to-use

spindle speed calculators that can be found on

the internet. All of these sources will help you

take into account all the applicable variables in

order to determine the best spindle speed for the

operation.

Cutting Speed (FPM) x 12

*Recommended

Dia. of Cut (in inches) x 3.14

= SpindleSpeed (RPM)

*Double if using carbide cutting tool

Figure 84. Spindle speed formula for lathes.