-56-

For Machines Mfg. Since 7/09

Model SB1016/SB1036

OPERATION

Half Nut Lever

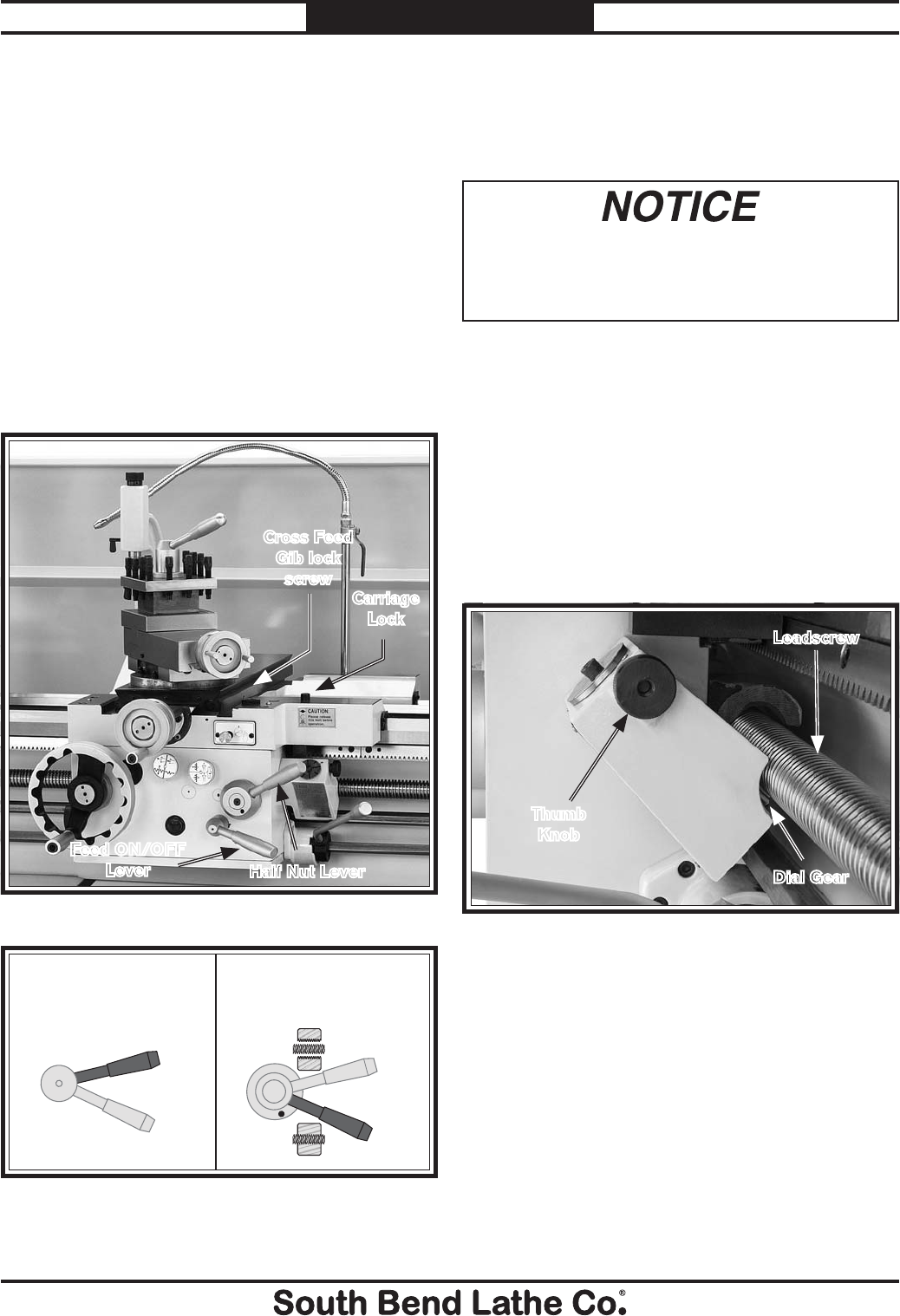

The half nut lever locks the carriage to the

leadscrew which moves the cutting tool along the

length of the workpiece (Figures 93–94).

When threading, we recommend using the

slowest speed possible and avoiding deep

cuts, so you are able to disengage the half nut

and prevent an apron crash!

Threading

If you are unfamiliar with how to cut threads on

a lathe, we strongly recommend that you read

books, review industry trade magazines, or get

formal training before beginning any attempting

any threading projects.

Power Feed Lever

The feed ON/OFF lever must be in the fully up

disengaged position or the internal lockout will

prevent the half nut lever from applying the half

nut. Also to avoid shearing the leadscrew shear

pin, the carriage lock (Figures 93–94) must be

loosened before threading begins.

Figure 93. Carriage controls.

Cross Feed

Gib lock

screw

Carriage

Lock

Half Nut Lever

Feed ON/OFF

Lever

Thread Dial & Chart Overview

The numbers on the thread dial are used with

the thread dial chart to show when to engage

the half nut during inch threading or threading

Witworth threads. The thread dial gear must

be engaged with the leadscrew for this to work.

Loosen the knurled thumb knob on the thread

dial, pivot the dial gear into mesh with the

leadscrew, then tighten the hand knob (see

Figure 95).

Figure 95. Thread dial gear engaged with the

leadscrew.

Leadscrew

Dial Gear

Thumb

Knob

Figure 94. Feed ON/OFF lever and half nut positions

for threading.

Engaged

Disengaged

Engaged

Disengaged

Halfnut Lever

and Halfnut

Feed Control

Lever