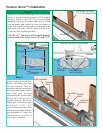

Lubricate both right

hand and left hand gear

assemblies, with the

grease provided. Place

the opener over the 1"

torsion tube and

between the two gear

assemblies. Center the

opener mounting bracket over the mounting support.

Lift the opener slightly and slide the left hand gear

assembly over so that the left hand drive gear meshes

with and rests on the teeth of the left hand gear assembly.

Repeat for right hand gear assembly. Plug motor power

cord into the opener.

Tighten the 3/8" square head bolt on the left hand gear

assembly. Adjust the opener and right hand gear

assembly so that there is a minimum 1/8" spacing

between the opener and the left hand gear assembly.

Now, adjust the right hand gear assembly, so that there

is a minimum 1/8" spacing between opener and the gear.

Tighten the 3/8"

square head bolt

on the right hand

gear assembly.

8

Step 3

Step 4

GREASE

PACKET

Adjust the mounting bracket so that it fits flush with the

header/ mounting support. Tighten the 5/16-18 nuts. Next,

level the opener with the torsion tube and door. Near the

cable drum, measure the distance from the torsion tube to

the top of the door. This dimension must be the same at the

opener point on the torsion tube to the door. Adjust the

opener vertically (if necessary) to accommodate this. Mark

a line under the mounting bracket when the torsion tube

and top of door are parallel. Keeping the mounting bracket

aligned with the line, secure the bracket to the mounting

support by first pre-drilling the lag screw locations with 3/

16” dia. bit and fastening with (2) 5/16” x 1-5/8” lag screws.

Step 5

GEAR ASSEMBLIES

1” TORSION

TUBE

1” TORSION

TUBE

OPENER

RIGHT HAND

DRIVE GEAR

1/8”

1/8”

OPENER

LEFT HAND

GEAR

ASSEMBLY

RIGHT HAND

GEAR

ASSEMBLY

3/8” SQUARE HEAD BOLT

PLUG IN MOTOR

POWER CORD

GREASE

ALL TEETH

IN GEAR

(2) 5/16” X 1-5/8”

LAG SCREWS

MOUNTING

BRACKET

SUPPORT

FOUNDATION

5/16-18 NUTS