-6-

Model G0746/G0749 (Mfg. Since 3/13)

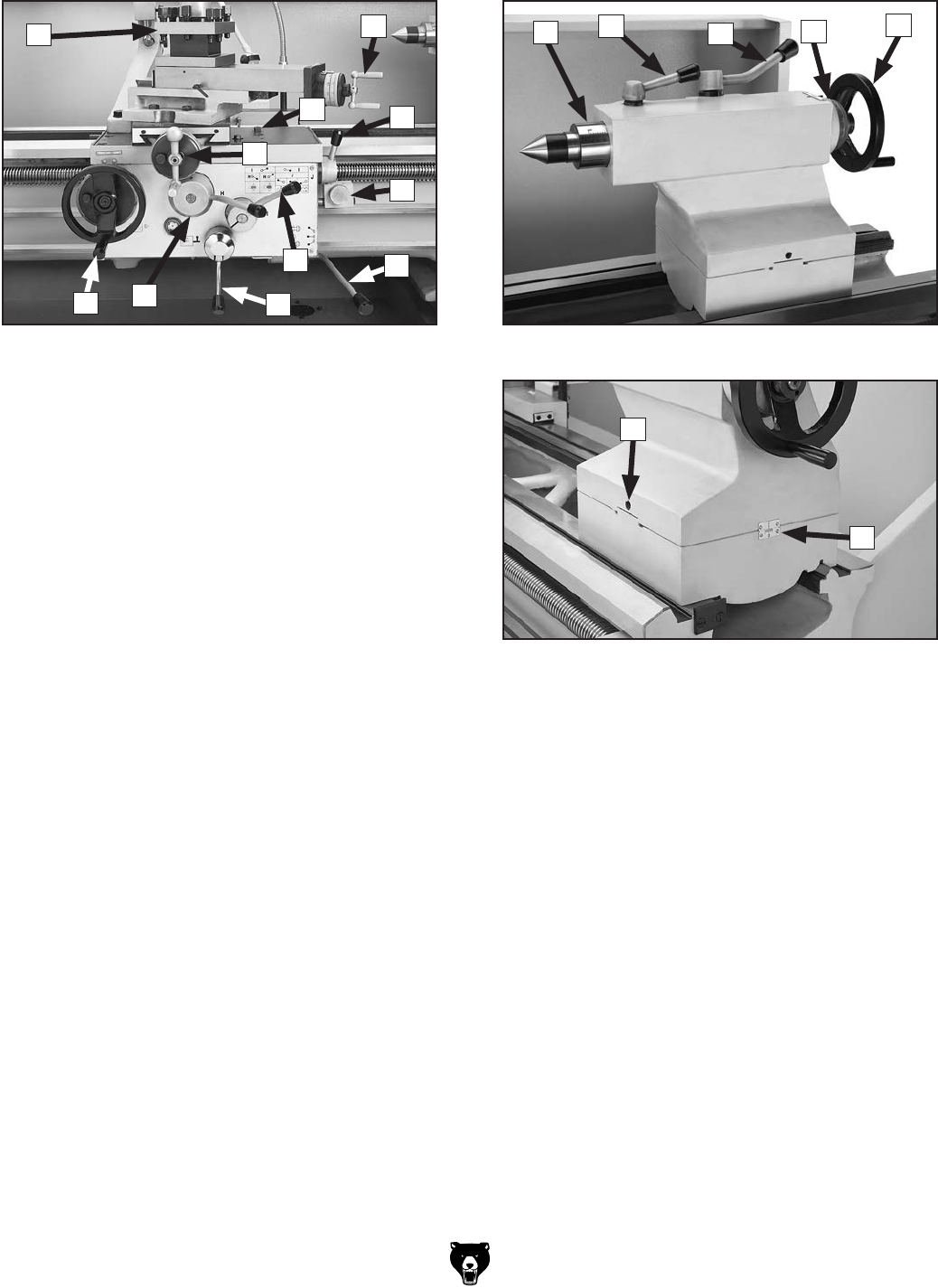

Tailstock

Figure 5. Additional tailstock controls.

S. Quill: Holds centers and tooling.

T. Quill Lock Lever: Secures quill in position.

U. Tailstock Lock Lever: Secures tailstock in

position along the bedway.

V. Graduated Scale: Indicates quill movement

in increments of 0.001" with one full revolu-

tion equaling 0.200" of quill travel.

W. Quill Handwheel: Moves quill toward or

away from spindle.

X. Tailstock Offset Screws: Adjusts tailstock

offset left or right from spindle centerline (1 of

2).

Y. Offset Scale: Indicates relative distance of

tailstock offset from spindle centerline.

Figure 6. Tailstock controls.

X

Y

W

T

U

V

S

H. 4-Way Tool Post: Holds up to four different

types of tooling, making it quick and easy to

switch tool type for different types of turning

operations.

I. Compound Rest Handwheel: Moves tool

toward and away from workpiece at preset

angle.

J. Carriage Lock: Secures carriage in place for

greater rigidity when it should not move.

K. Feed Selection Lever: Selects power feed

for carriage or cross slide.

L. Thread Dial: Indicates when to engage the

half nut during inch threading operations.

M. Spindle Lever: Starts, stops, and reverses

direction of spindle rotation.

N. Feed Lever: Enables carriage for power feed

or threading operations.

O. One-Shot Oiler: Pumps oil from apron res-

ervoir to lubricate carriage ways.

P. Half Nut Lever: Engages/disengages half

nut for threading operations.

Q. Carriage Handwheel: Moves carriage along

the bed.

R. Cross Slide Handwheel: Moves cross slide

toward and away from workpiece.

Carriage

Figure 4. Carriage controls.

H

J

I

O

K

L

M

P

Q

N

R