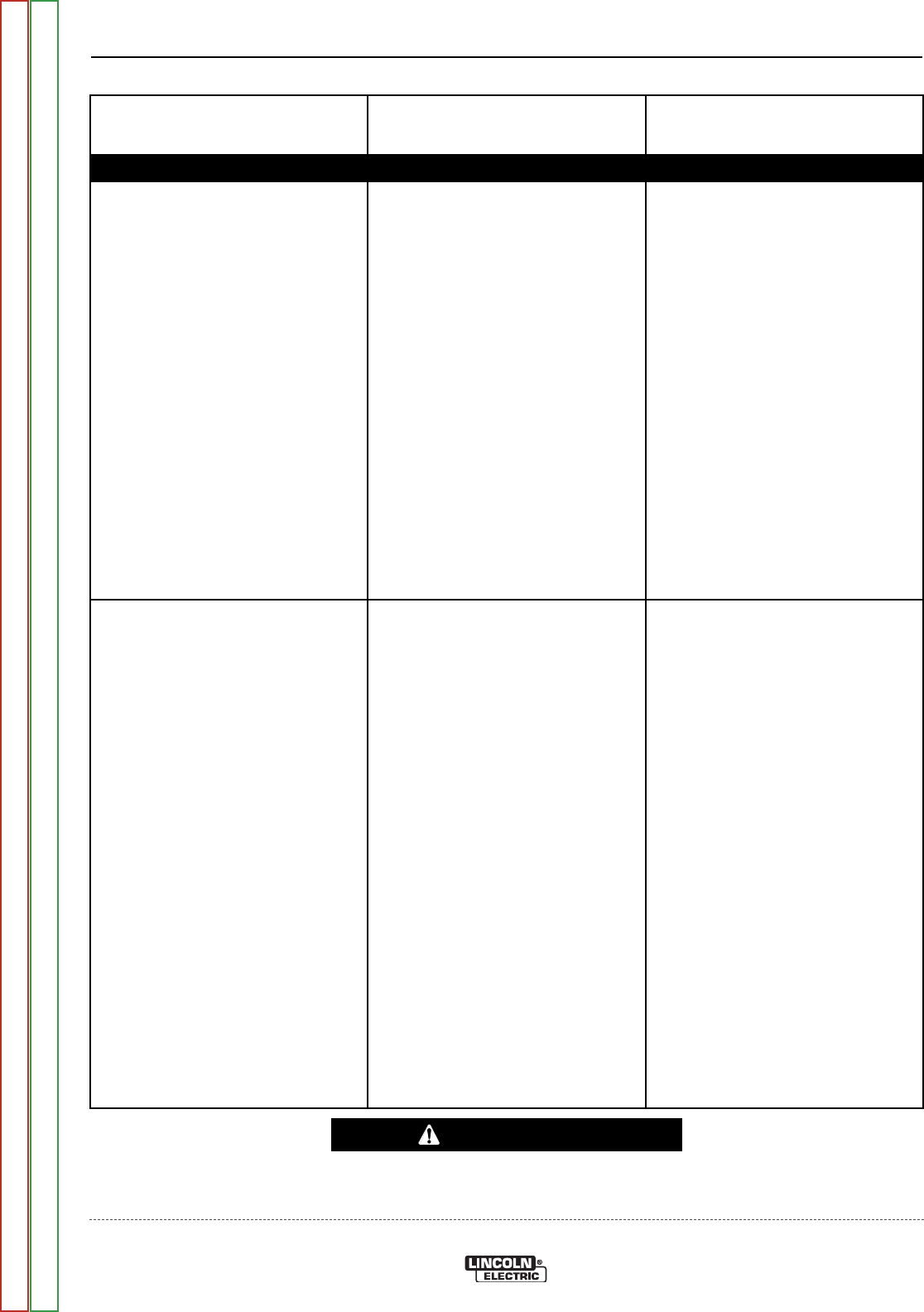

OUTPUT PROBLEMS

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely,

contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed.

Call 1-888-935-3877.

CAUTION

No welding output in either Stick or

CV modes. Also no auxiliary power.

The engine operates normally.

1. Check the brushes for wear and

proper contact to the rotor slip

rings.

2. Make sure the engine is operat-

ing at the correct high idle speed

(1900RPM).

3. Check for loose or faulty con-

nections or leads on the auxil-

iary power studs in the control

box. See the Wiring Diagram.

1. Perform the Rotor Resistance

Test.

2. Perform the Flashing and

Rotor Voltage Test. If the

"flashing" voltage is not pre-

sent the leads 6,5H,200B,

#201 or #200 may be faulty.

See the Wiring Diagram. Also

make sure that lead #5P has

continuity (zero ohms) to

ground.

3. Check the field diode bridge

and capacitor. Replace if nec-

essary.

4. Perform the Stator Voltage

Test.

No auxiliary power at the recepta-

cles. The welding output is normal

and the engine operates normally.

1. The circuit breakers may be

tripped. Reset if necessary.

2. Check for loose or faulty con-

nections at the auxiliary recepta-

cles.

1. Check the wiring between the

auxiliary receptacles, the con-

nection studs in the control box,

and the main stator. See the

Wiring Diagram.

2. Perform the Stator Voltage

Test.

3. Check GFCI receptacles.

NOTE: The machine must be at

high idle to reset the GFCI

receptacles

TROUBLESHOOTING AND REPAIR

F-5 F-5

VANTAGE® 500

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC