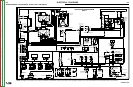

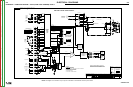

ELEcTricaL DiaGramS

G-10

vaNTaGE® 500

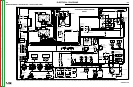

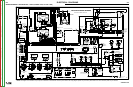

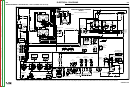

SchEmaTic - cOmpLETE machiNE - G4848 (cODES 11180, 11415 & 11468 DEuTz) paGE 1

G4848

VA

NTA

GE 500

DE

UT

Z

MAC

HI

N

E SC

HEM

ATIC

NONE

G4487

B.

M

UTER

N.S.

DO NO

T

SC

AL

E

T

HIS DR

A

WING

D

RAWN

BY:

DESIG

N

I

NFO

RMATI

ON

ENG

I

NEER:

AP

PRO

VED

:

EQ

UIP

M

ENT

TYPE:

SUBJECT:

SCA

L

E:

UF

CRM36466

1

PAGE ___ OF

___

2

E

NGI

N

EE

RI

NG

CO

NT

RO

LLE

D

MA

NU

FA

CT

URE

R:

No

THIS DOCUMENT CONTAINS PROPRIETAR

Y

INFORMATION OWNED B

Y

LINCOLN GLOBA

L, INC.

AND MA

Y

NOT BE DUPLICATED, COMMUNICATED

TO O

THER PARTIES OR US

ED FOR

AN

Y

PURPOS

E WITHOU

T

THE EXPRES

S WRIT

TEN PERMISSION

OF LINCOLN GLOBAL, INC.

PRO

PRIETARY & C

ONFIDENTIAL:

A

08/03/2004

t

MAT

ERI

A

L TO

L

ER

ANC

E ("

"

) TO A

GR

EE

WITH

PU

B

LI

SH

ED

ST

ANDARD

S.

ON A

LL

AN

GL

E

S I

S ± .5 OF

A D

E

GR

EE

ON

3

PLACE

D

E

CIM

ALS

IS

± .

002

ON 2

PL

AC

E D

ECIM

AL

S I

S ± .02

UNLESS OTHERWISE SPECIFIED TOLERANCE:

M

ANUF

ACTURING TO

L

ER

ANC

E

P

ER

E

2056

R

ele

ased A.01 from

X

CHAN

GE

D

ET

AIL:

REFER

ENCE:

MA

T

ERI

AL

DIS

PO

SI

T

ION:

AP

PRO

VA

L

DA

T

E:

PROJ

EC

T

NUMBER:

DOCUMEN

T

NUMBER:

DOCUMEN

T

REV

ISI

ON:

G4848

TH

RE

E

PHASE

RE

CTIFI

ER

3200uf

300vdc

SHUNT

50

M

V=400

AM

PS

206S

204S

LEFT CHOKE

CURRE

NT L

EV

EL

FE

E

D

BAC

K

SI

GN

AL

POSITI VE

OUTPUT

TERMINAL

NEGATI VE

OUTPUT

TERMINAL

B

Y-

PASS

P

C

BOA RD

206B

208

5A

A

C

AU

X.

POWER

42 V

OLT

AC

WI

R

E F

EEDER

POWER

41

42

FO

U

R

P

OL

E 1800

R

PM

ALT

ERN

AT

OR

120 V

OLT

AC

POWE

R F

OR

R

OT

O

R FI

EL

DCI

RC

UIT

12 V

OLT

B

ATT

ERY

EN

GI

NE

ST

A

RT

ER

S

OL

EN

OI

D

ST

A

RT

B

UTT

O

N

S

WIT

CH

RU

N-STOP SWIT

CH

SHOWN I

N RUN

POS.

FR

AM

E

GROUND

W2

W2

W3

W3

W5

W4

W5

W4

W1

W1

W6

W6

3

5

6A

PERIPHERAL

PCBOARD

PULLCOIL

PCBOARD

(J31-9)

5T

229

(J31-4)

232F

405 (J31

-11)

(J32-6)

234

(J31-6)

262A

270 (J31

-8)

271 (J32

-7)

SENDER

SENDER

S

WIT

CH

TEM

PER

AT

URE

OIL

PRESSURE

S

WIT

CH

EN

G.

PRO

T.

FU

EL

TEM

P.

241

228

405 (J43

-5)

271 (J43

-4)

200 (J43

-3)

227 (B1)

IDL

E

S

OL.

P

ULL

C

OIL

5S (

B4)

232N (

B2)

SH

UT

DOW

N

C

OIL

+12

V

OLT

S

RUN

EN

GI

NE

ST

A

RT

ER

+12

V

OLT

S

RUN

+12

V

OLT

S

RUN

201

200

200A

HOUR

MET

ER

+

21

WI

R

EF

EEDER

V

OLTM

ET

ER

P

OL

A

RIT

Y

S

WIT

CH

206A

208A

231

238A

+

160 V

DC

6

5H

270 (J43

-6)

_

+

236B

232H

232D

C

B 15

A

238B

236A

C

E

LEFT

CHOPPE

R

P

C

BOARD

G

AT

E SI

GN

AL

IG

BT (8)

B7

B8

B6

B3

B5

B2

B4

B1

+CO

M

FLY

BACK

DI

ODE

S (6)

FILTE

R

CAPA

CIT

OR

S (4)

+

10,000u

F x4

p/n L118

45-1

C

E

RI

G

HT

CHOPPPPE

R

P

C

BOA RD

G

AT

E SI

GN

AL

IG

BT (8)

B7

B8

B6

B3

B5

B2

B4

B1

+CO

M

FLY

BACK

DI

ODE

S (6)

FILTE

R

CAPA

CIT

OR

S (4)

+

10,000u

F x4

p/n L118

45-1

RIGHT

C

HOKE

D

C

BU

S

V

OLT

AGE

90+/-10V

D

C

@

HI I

DL

E

AR

C

V

OLT

AG

E F

EEDBAC

K SI

GN

AL

R1

O

UT

P

UT

CO

NT

R

OL 10

K

77 (J7-

1)

76 (J7-

4)

75 (J7-

5)

R2

ARC

CO

NT

R

OL 10

K

279 (J7

-6)

278 (J7

-7)

277 (J7

-8)

(J3-14)

257

(J3-7)

256

IDL

E

R

S

WIT

CH

(J1-4)

2

(J1-3)

4

W

EL

D T

E

RM.

S

W.

MO

DE

S

WIT

CH

CC

CV

PI

PE

TIG

(J7-9)

214

(J7-14)

218

(J7-15)

220

(J7-16) 222

260 (J3

-4)

261 (J3

-3)

TO

R

OI

D-

SENSE

S

AC

POWE

R T

O

A

CTI

V

AT

E

IDL

ER

WE L DC ON T RO L

PCBOARD

(J2-5) 2

26

(J2-4) 4

04

204S (J6-1)

206S (J6-2)

208B (J3-15)

23(J3-10)

25(J3-9)

5G (J2-3)

R

EM

OT

E

CO

NT

R

OL 10

K

77A (J1-11)

76A (J1-14)

75A (J1-10)

10 V

0-10 V

0 V

10 V

-15 V (

W/

O

P

OT.)

0 V

0 V

15 V

15 V

0 V

TWI

ST

ED

P

AI

R

(TO

AM

PHEN

OL)

(TO

AM

PHEN

OL)

2A

4A

(TO

AM

PHEN

OL)

31

32

41A

A

B

C

D

E

F

77A

21

42A

75A

GN

D-

A

4A

2A

76A

77B

76B

75B

GROU

ND

AMPHEN

OL

IN

P

UT T

O

AM

PHEN

OL

115V

AC

CO

NT

AC

T

OR

W

OR

K

RE

MOTE

CO

NT

RO

L

42V

AC

GROU

ND

AMPHEN

OL

J

A

D

C

H

B

K

E

F

G

I

77B

76B

75B

GN

D-

B

4B

2B

4B

2B

13(J3-8)

14(J3-16)

(J1-5) 5

00

(J1-13)

500

500 I.D. J

UM

PE

R (

Part

of amphe

nol plug a

nd

lead asse

mbly.)

+15

V

@ L

O

W I

DL

E T

O

P

ULL

C

OIL

BOARD

LO

W I

DL

E

S

OL

EN

OI

D

H

OL

D

C

OIL (0

V

@ L

O

W I

DL

E)

TWI

ST

ED

P

AI

R

TWI

ST

ED

P

AI

R

R

OT

O

R FL

AS

HI

NG

Located o

n back of

control pa

nel.

P/

N

G4107-1

Located o

n wiring behind

receptacle

s.

Open

Circuit

Volts:

CC

Max

Min

5858

58

58

58

26

12

12

CV

P

ipe

Tig

Control board com

mon is

at welder positive outp

ut

and shunt

Control board circuits

associated with J2 are

part

of engine

electrical syst

em and a

re comm

on to

frame g

round (

negative b

attery te

rminal.

Rotor Flashing: +12 volts

@ 0.5 amps

until gene

rator buil

ds up

then +160 volts @ 0 am

ps.

S

wich closed for high idle.

W

EL

D

AMM

ET

ER

W

EL

D

V

OLTM

ET

ER

(J4-1 to

10)

(J5-1 to

10)

Meters dis

play setpoin

t volts or a

mps when not welding.

Meters dis

play actual v

olts and a

mps when

welding.

Hold function displays act

ual volts an

d amps fo

r

approxim

ately 5 seco

nds after welding stop

s.

During this hold display t

he right

most deci

mal point will blink.

23A(J3-12)

25A(J3-11)

14A

13A

14

13

TWI

ST

ED

P

AI

R

(J2-6) 2

32D

+12

V F

R

OM

RU

N/

ST

O

P

S

WIT

CH

R4

50

OH

M

100 W

R4 is located on top of

chopper

power module

assembly.

5J

1

1

1

4

4

4

404 (J43

-8)

IDL

E

S

OL.

H

OL

D

C

OIL

405A (J31-12)

247 (J32

-1)

+12

V

OLT

S

RUN

FIEL

D FL

AS

HI

N

G

ALT

ERN

AT

OR

IG

BT'

S, FL

YBAC

K

DI

ODE

S

AND

FILTE

R

CAPA

CIT

OR

S

AR

E I

NT

EGR

AL

TO

CHOPPE

R M

OD

UL

E

S

AN

D

N

OT

INDI

VI

DU

ALL

Y

RE

PL

ACEA

BL

E.

STAT

OR

W

EL

D

WI

N

DI

NGS

R

OT

O

R FI

EL

D

SLI

P

RI

NGS

RE

MOT E

CO

NT

RO

L

OIL

PRES

S.

FU

EL L

VL.

SENSOR

Chokes are mounted

on

power module assem

bly

behind ou

tput ter

minal pan

el.

Po

wer

Supply

to Control

Board

P

WM

S

ignal to Chopper

15 volt @ 20 kHz

Chopper modules a

re located

on power

module as

sembly be

hind outp

ut termin

al

panel.

Rectifier is located on p

ower module

assembly b

ehind out

put contr

ol panel.

Shunt on back of positiv

e

output te

rminal

Located o

n back of

output pa

nel

between terminals

60 TO 65 V

A

C

PHAS

E T

O

PHASE

AT

HI

G

H IDL

E

REV

OL

VI

N

G FI

EL

D

RE

SI

ST

ANC

E

APPRO

X.

25 O

HM

S

@ 75F

Field capa

citor and

diode brid

ge

located on

lower rear of fan b

affle

on right si

de of mac

hine.

Battery voltage:

12.6 volts

at rest

14 volts en

gine

running

Located o

n lower left

side of con

trol

compart

ment

Located o

n rear

of control

panel

left side.

0.2 O

HM

11 O

HM

S

3.5 O

HM

S

Oil

Pressure

S

witch

closes on low

oil pressur

e.

Temper

ature S

witch

closes on hi

gh

tempera

ture.

Engine protection

circuit. La

mp test

and 30sec

ond

delay one

ngine

start.

+20

Volts from pull

coil board

+10

Volts

Voltage

Regulators

+10

Volts

+20

Volts

YEL

LO

W

LED

230 O

HM

S

EM

PT

Y

30 O

HM

S F

ULL

10 O

HM

S

@ 0

P

SI

100 O

HM

S

@ 75

P

S1

500-600

O

HM

S

C

OL

D

50-100 OHM

S

H

OT

(S

E

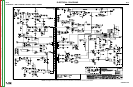

E

SHE

ET 2 F

OR

SIMPLIFI

ED

CO

NT

R

OL

BOARD

SCH

EM

ATI

C)

(SIM

PLIFI

E

D

BOARD

SCH

EM

ATI

C)

(SIM

PLIFI

ED

BOARD

SCH

EM

ATI

C)

250 (J3

-5)

250 (J3

-1)

Jumper

required

for outp

ut.

Low oil

pressure

or

high

tempera

ture

shutdown

4

3 TO 5 - 120 V

A

C 1

PHASE

6A T

O 5 -120

VA

C 1

PHASE

3 TO 6

A - 240

VA

C 1

PHASE

3, 4 A

N

D 6

A - 240

VA

C 3

PHASE

LO

CKO

UT

S

WIT

CH

6

5H

Located in

top of fu

el tank

Located o

n front p

anel

Located in

engine bl

ock

Right side, rear

Located in

engine th

ermostat

housing

Located o

n front p

anel

Located in

side engin

e blower housing

Solenoids located on rig

ht front

of engine

J55-3

J55-4

J54-1

J55-2

J54-2

281 (J43

-2)

AL

T.

YEL

LO

W

LED

243 (J32

-4)

239 (J32

-8)

W

B-

B+

D+

ALT

ERN

AT

OR

3/4 Second Timer

LE

A

D

C

OL

O

R

COD

E:

B-

BL

AC

K

O

R

GRAY

G-

GREEN

O-

ORANGE

R-

RE

D

O

R

PI

NK

U-

BL

UE

W-

W

HIT

E

Y-

Y

ELL

OW

C

OM

PONE

NT

V

AL

U

E

U

NIT

S:

CAPA

CIT

O

R: MF

D/

V

OLT

S

RE

SI

ST

O

R:

O

HM

S/

W

ATT

S

CONNE

CT

O

R

PI

N

N

UM

BER

S:

VI EW

OF

CONNEC

TO

RONPCBOARD

1

2

6

7

12

LA

TCH

EX.

12

PI N CONNEC

TO

R

LABELS:

C

OMM

ON

FR

AM

E

GROUND

EA

RT

H

GROUND

G-10

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC