OPERATION

ENGINE OPERATION

STARTING THE ENGINE

1. Open the engine compartment door and check that

the fuel shutoff valve is in the open position (lever to

be in line with the hose).

2. Check for proper oil level and coolant level. Close

engine compartment door.

3. Remove all plugs connected to the AC power recep-

tacles.

4. Set IDLER switch to “AUTO”.

5. Set the RUN/STOP switch to “RUN”. Observe that

the engine protection and battery charging lights are

on. The engine protection light may turn off after 5

seconds or remain on until the engine is started.

6. Within 30 seconds, press and hold the engine

START button until the engine starts. If the engine

does not start within 30 seconds the RUN/STOP

switch must be returned to the STOP position, then

return to step 5.

7. Release the engine START button when the engine

starts.

8. Check that the engine protection and battery charg-

ing lights are off. Investigate any indicated problem.

NOTE: The engine will go through a 3 minute warm-up

cycle if cold. If the engine coolant is still warm

from recent operation, the engine will go imme-

diately to high idle and then to low idle if the idle

switch is in the “AUTO” position.

COLD WEATHER STARTING

With a fully charged battery and the proper weight oil,

the engine should start satisfactorily even down to

about 0°F(-18°C). If the engine must be frequently

started below 10°(-12°C), it may be desirable to install

the optional ether start kit (K887-1). Installation and

operating instructions are included in the kits.

STOPPING THE ENGINE

Switch the RUN/STOP switch to “STOP”. This turns off

the voltage supplied to the shutdown solenoid. A back-

up shutdown can be accomplished by shutting off the

fuel valve located on the fuel line.

BREAK-IN PERIOD

The engine used to supply power for your welder is a heavy

duty, industrial engine. It is designed and built for rugged use.

It is very normal for any engine to use small quantities of oil

until the break-in is accomplished. Check the oil level twice a

day during the break-in period. In general this takes 50 to 100

hours of operation.

IMPORTANT

IN ORDER TO ACCOMPLISH THIS BREAK-IN, THE UNIT

SHOULD BE SUBJECTED TO HEAVY LOADS, WITHIN

THE RATING OF THE MACHINE. AVOID LONG IDLE RUN-

NING PERIODS.

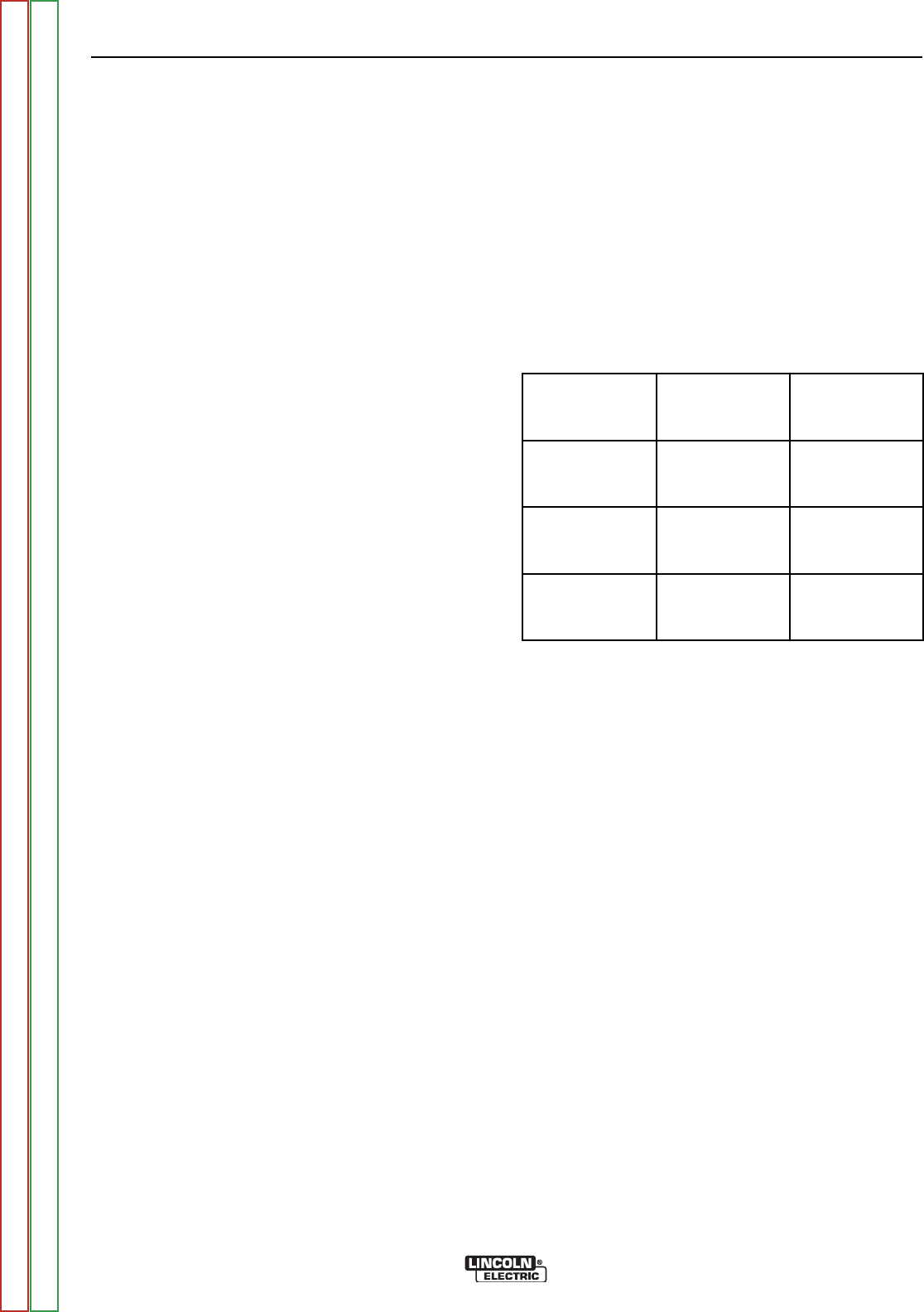

TYPICAL FUEL CONSUMPTION

Refer to Table B1.1 for typical fuel consumption of the VAN-

TAGE 500 Engine for various operating scenarios.

B1.7 B1.7

VANTAGE® 500

Table B1.1 – DEUTZ F3L 912

ENGINE FUEL CONSUMPTION

Deutz F3L 912

44.2 HP

@1800 rpm

Running Time

for 25 Gallons

(Hours)

High Idle

No Load

1900 rpm

.66 gallons/hour

(2.50 liters/hour)

37.9

DC-CC

Welding

500A @40V

1.94 gallons/hour

(7.34 liters/hour)

12.9

Auxiliary Power

12,000 VA

1.31 gallons/hour

(4.96 liters/hour)

19.1

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC