MAINTENANCE

D1.5 D1.5

VANTAGE® 500

4. Slide the new element onto the grommet post on

the bottom of the filter header until the element no

longer easily moves up into the filter header. Now

rotate the element (it may take almost 1 full turn)

with a slight upward pressure until the element

begins to further engage the header. With the prop-

er orientation now established, apply additional

pressure to seat the element in the filter header.

You should feel the element “pop” into place when

properly seated.

NOTE: The element will only go on one way. Never use

excessive force when mounting the element to the

header.

5. Slide the quick change ring up over the element and

rotate counter clockwise until an audible click or

pop is heard. If you do not hear the click, you have

not rotated the ring far enough and the element is

not in the locked position. Another indication that

the ring is in the locked position is that one set (it

doesn’t matter which one) of arrows located on the

outside of the ring should be located directly under

the air vent valve.

6 . Open the fuel shutoff valve (lever in line with the

hose).

7 . Open the air vent valve on the front of the filter

header until fuel emerges free of air bubbles. Then

close the air vent valve.

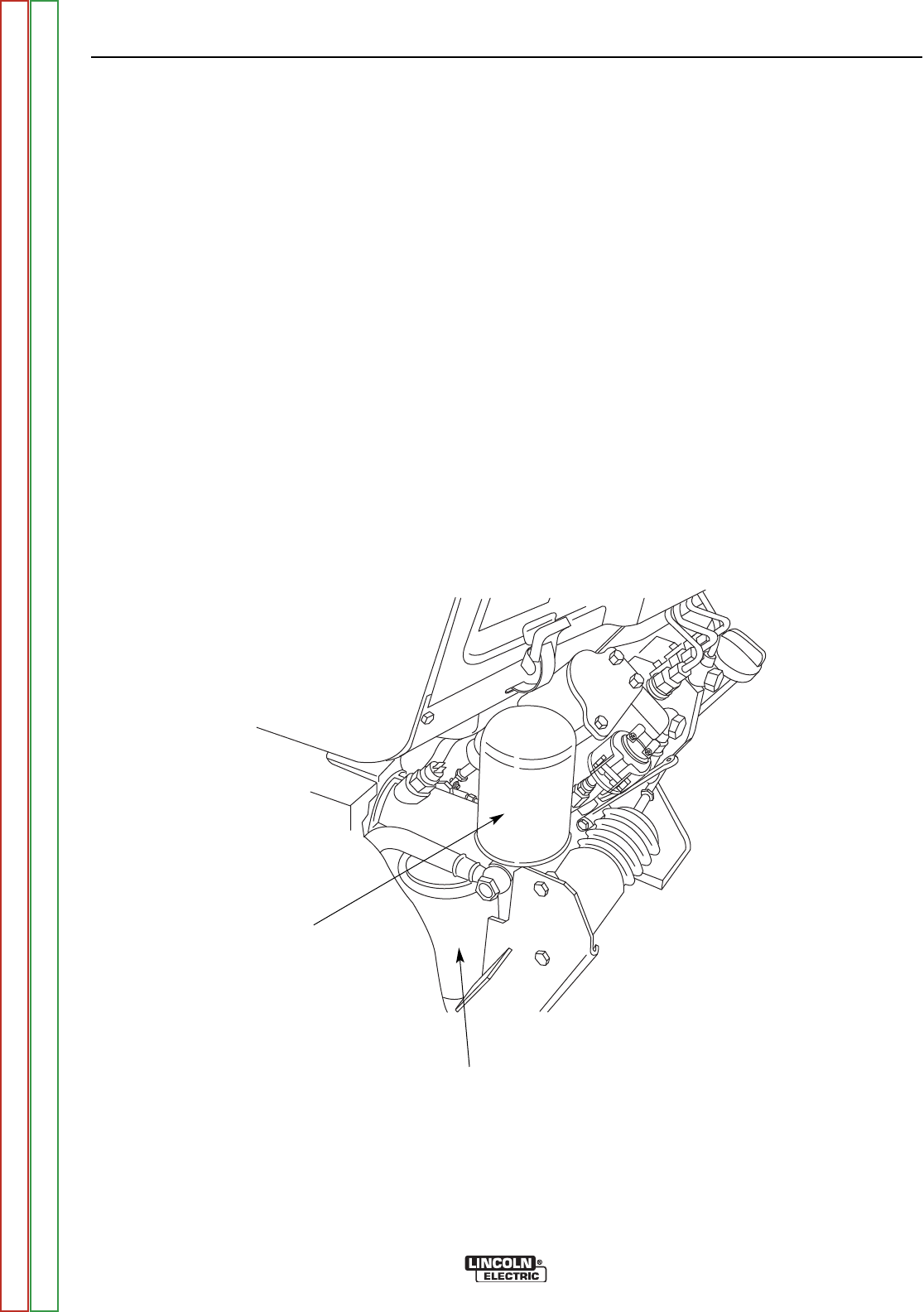

Secondary Fuel Filter: The Secondary Fuel Filter is a

spin-on cartridge type mounted directly to the engine.

Consult your engine Operator’s Manual for complete

information on service intervals and element changing

procedures.

FIGURE D1.3 – SECONDARY FUEL FILTER

SECONDARY

FUEL FILTER

OIL

FILTER

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC