#200A

#200B

#201

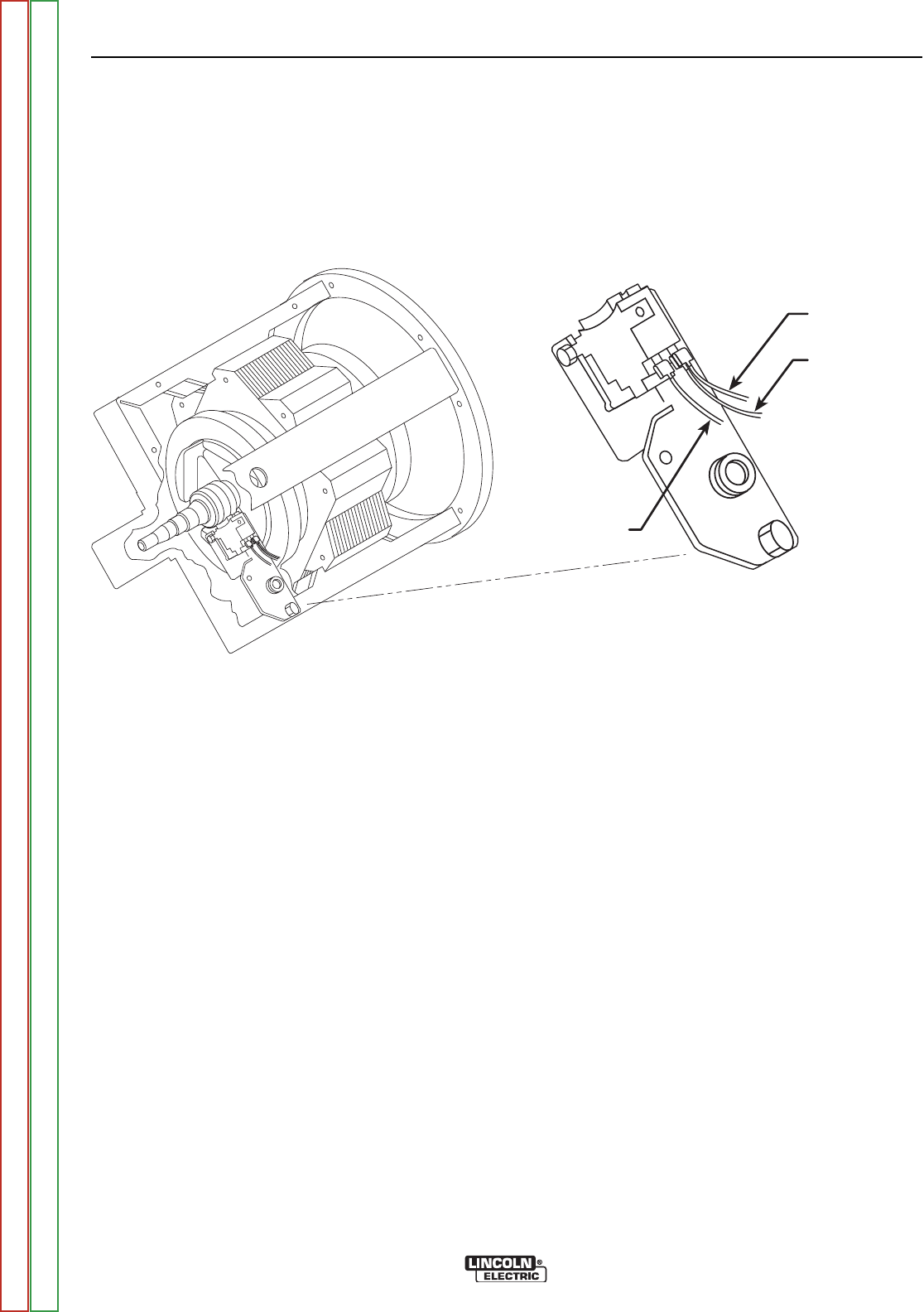

FIGURE F.9 – ROTOR BRUSH LOCATION

FLASHING AND ROTOR VOLTAGE TEST(CONTINUED)

PROCEDURE

1. Using the 3/8" wrench, remove the sheet metal

screws from the right front case side.

2. Carefully remove the right case side.

3. Set the volt/ohmmeter to the DC volts position.

4. Locate leads #200A and #201A at the rotor brush-

es.

NOTE: Cut any cable ties necessary to perform the

test.

5. Connect the positive meter probe to lead #200B

and the negative meter probe to lead #201.

6. Start the engine and run it at high idle speed (1900

RPM). Check the voltage reading on the meter. It

should read approximately 120 VDC.

7. If the voltage reading is low or not present, the gen-

erator field is not functioning properly. Perform the

Rotor Resistance Test. Also check the field diode

rectifier bridge, filter capacitor, and associated

leads and connections. See the Wiring Diagram.

NOTE: The normal flashing voltage is approximately

9VDC. This is battery voltage, which is

processed through the Pull Coil PC Board.

This voltage must be present during start-up to

"flash" the rotor field.

8. If the rotor voltage readings are normal, the field

circuit is functioning properly. Replace any cable

ties cut during the test. Install the right case side.

TROUBLESHOOTING AND REPAIR

F-32 F-32

VANTAGE® 500

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC