B-3

OPERATION

B-3

1. Power Switch - Place the lever in the “ON” position

to energize the machine. When the power is on, the

fan will operate and the output will be energized in

SMAW modes. GTAW mode requires remote trig-

ger to energize the output.

2. Output Control - This controls the output current.

Control is provided over the entire output range of

the power source with 1 turn of the control knob.

This control may be adjusted while under load to

change power source output. When using remote

control this function becomes the limit setting.

3. Local/Remote Switch - Place in the “LOCAL” posi-

tion to allow output adjustment at the machine.

Place in the “REMOTE” position to allow output

adjustment at remote pot or amptrol. In Remote, the

machine output control pot is the limit setting for

remote control.

4. Mode Switch

GTAW

Optimized for touch start use. Triggering at

amphenol is required using an Arc Start Switch,

Amptrol or similar means. Short circuit current is

limited to approximately 25 amps to aid in touch

starting.

CC Soft

Best for EXX18 thru EXX28 stick elec-

trodes. Output energized when machine is on.

CC Crisp

Use this mode for stick welding with

EXX10 thru EXX14 electrodes. Output energized

when machine is on.

5. Hot Start - Controls the amount of starting energy

in SMAW.

INVERTEC V250-S

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

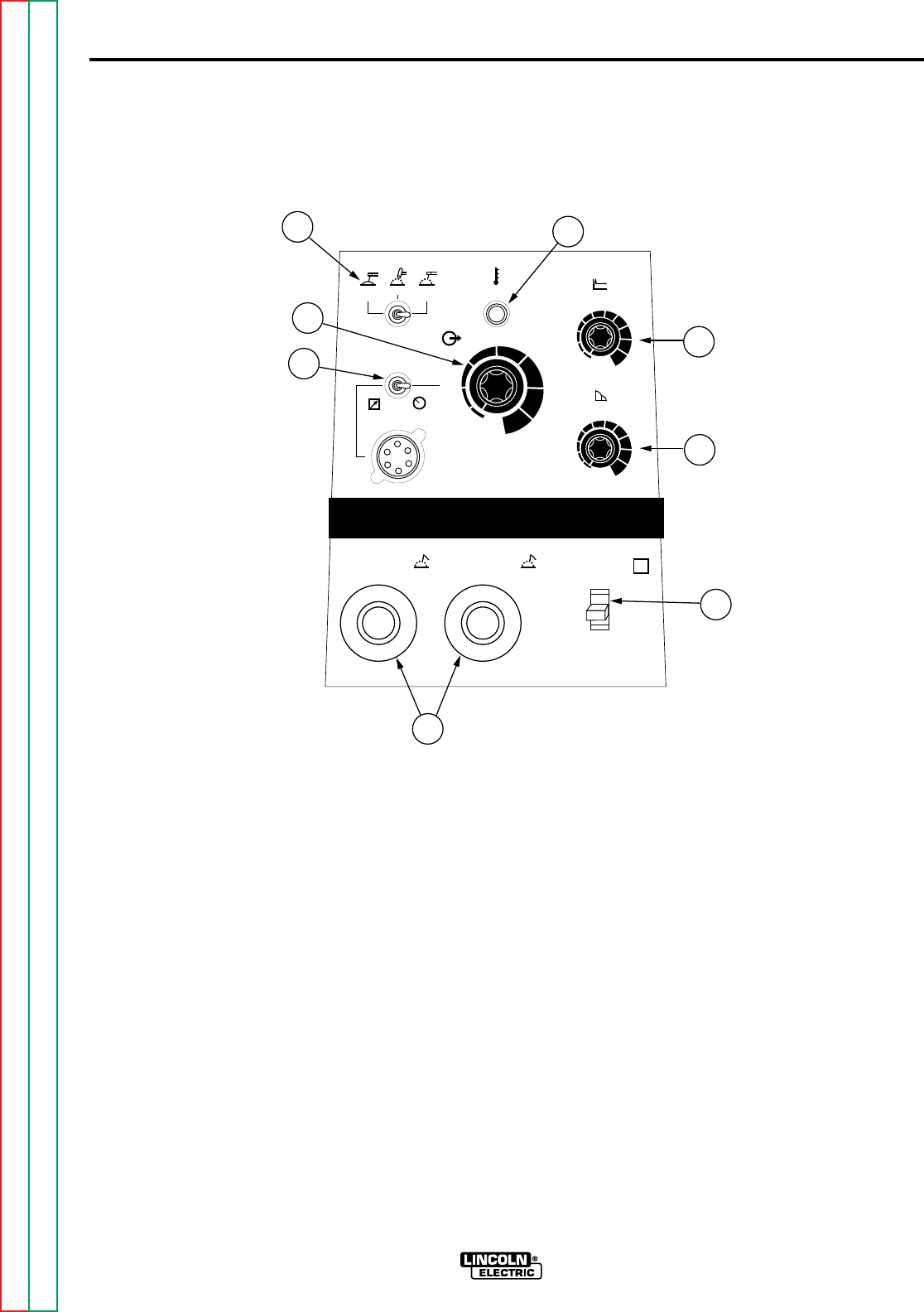

CONTROLS AND SETTINGS

All operator controls and adjustments are located on the case front of the V250-S. Refer to Figure B.1 and corre-

sponding explanations.

FIGURE B.1 — CASE FRONT CONTROLS.

O

I

INVERTEC V250-S

®

S

-

+

1

15

50

85

120

170

230

250

A

OUTPUT

SMAW

SOFT

GTAW

SMAW

CRISP

REMOTE

LOCAL

THERMAL

HOT START

1

2

3

4

6

7

8

9

10

5

0

ARC FORCE

1

2

3

4

6

7

8

9

10

5

0

1

2

3

4

5

6

7

8