Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-29

TROUBLESHOOTING & REPAIR

F-29

POWER BOARD VOLTAGE TEST (continued)

INVERTEC V250-S

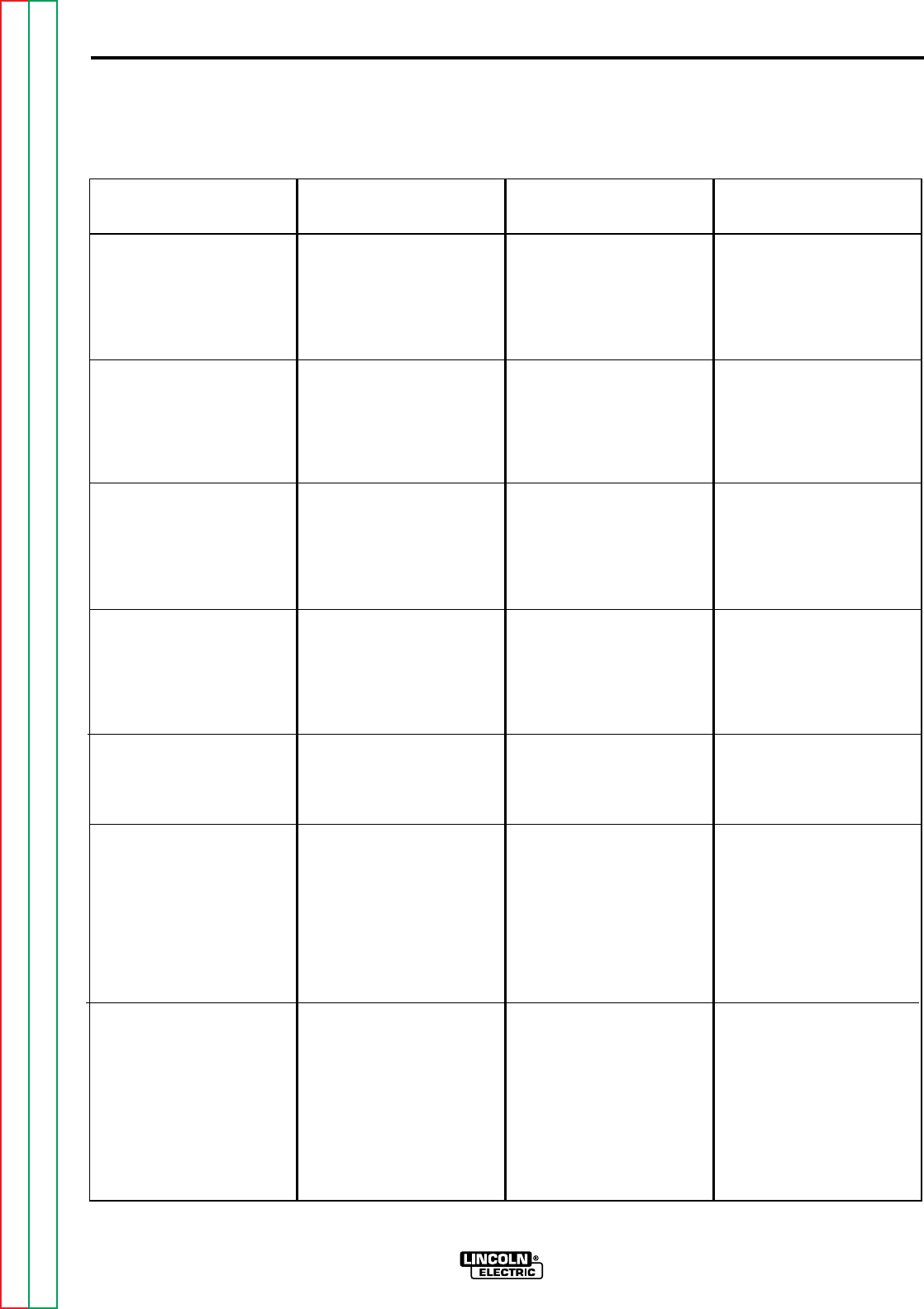

TABLE F.4. Power Board Voltage Test Points.

TEST DESCRIPTION

The PWM pulse drive from the

control board to the pulse

transformer primary located on

the power board.

The PWM pulse drive from the

control board to the pulse

transformer primary located on

the power board.

The PWM pulse drive from the

control board to the pulse

transformer primary located on

the power board.

The PWM pulse drive from the

control board to the pulse

transformer primary located on

the power board.

CR1 (charge relay) coil volt-

age.

This low voltage will be pre-

sent when the protection cir-

cuit has determined that the

filter capacitor voltage is

acceptable. Note: The CR1

charge relay should be acti-

vated.

This voltage will be present

unit the protection circuit

determines that the filter

capacitor is at an acceptable

level.

Note: The CR1 charge relay

will not be activated.

TEST POINTS

Lead #307 (2J6)

to

Negative output terminal

Lead #308 (1J6)

to

Negative output terminal

Lead #307 (2J6)

to

Negative output terminal

Lead #308 (1J6)

to

Negative output terminal

Lead #309 (6J6)+

to

lead #310 (3J6)

Lead #311 (4J6)+

to

lead #313 (5J6)-

Lead #311 (4J6)+

to

lead #313 (5J6)-

ACCEPTABLE

VOLTAGES

14VDC.

14VDC.

7VDC.

7VDC.

12VDC

0 to 1VDC.

15VDC.

TEST CONDITIONS

No load on the machine - the

mode switch in SMAW posi-

tion.

No load on the machine - the

mode switch in SMAW posi-

tion.

Machine loaded to 250Amps.

The output control R3 at the

maximum position.

Machine loaded to 250Amps.

The output control R3 at the

maximum position.

This voltage should be pre-

sent only after the protection

circuit as been satisfied.

If voltage protection circuit IS

satisfied.

If voltage protection circuit is

NOT satisfied.