F-17

TROUBLESHOOTING & REPAIR

F-17

6. If the Input Rectifier does not meet

the acceptable readings outlined in

Table F.2. the component may be

faulty. Replace.

Note: Before replacing the Input

Rectifier(D9) check the input

power switch (S1) and perform

the

Power Board Resistance

Test

. Also check for leaky or

faulty filter capacitors.

7. When installing a new Input

Rectifier, torque the mounting nuts to

44IN-LBS. A thin coating of Dow

Corning 340 Heat Sink Compound

(Lincoln E1868) is recommended.

Torque the lead terminals to 31IN-

LBS. See

Input Rectifier Bridge

Removal And Replacement

.

8. If the Input Rectifier is good be sure

to reconnect leads #207, #207A and

#209 to the correct terminals and

torque to 31IN-LBS. See wiring dia-

gram and Figure F.2.

INPUT RECTIFIER TEST (continued)

INVERTEC V250-S

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

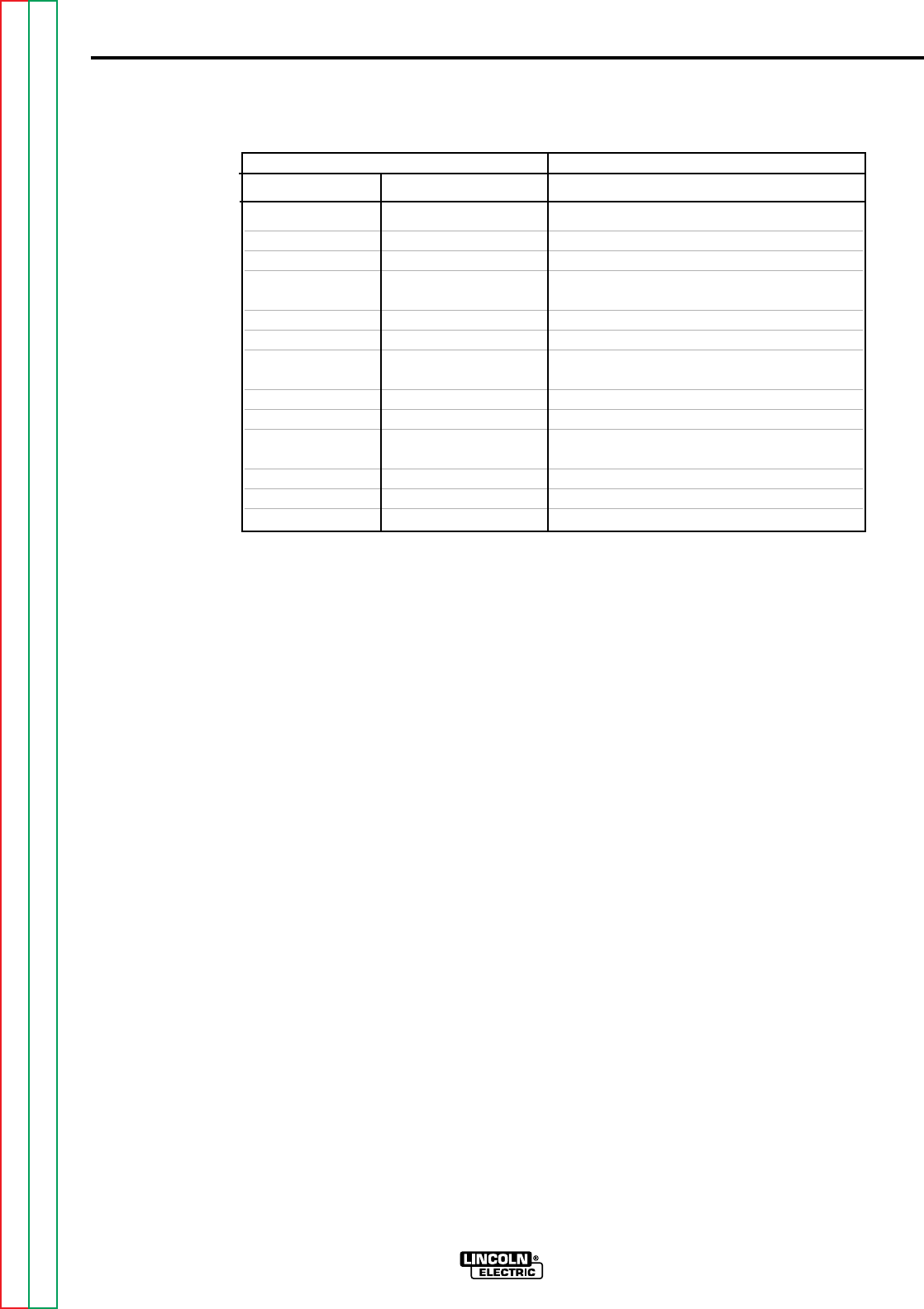

TEST POINT TERMINALS ANALOG METER X10 RANGE

+ Probe - Probe Acceptable Meter Readings

A 207 Greater than 1000 ohms

B 207 Greater than 1000 ohms

C 207 Greater than 1000 ohms

A 209 Less than 100 ohms

B 209 Less than 100 ohms

C 209 Less than 100 ohms

207 A Less than 100 ohms

207 B Less than 100 ohms

207 C Less than 100 ohms

209 A Greater than 1000 ohms

209 B Greater than 1000 ohms

209 C Greater than 1000 ohms

TABLE F.2 Input Rectifier Test Points