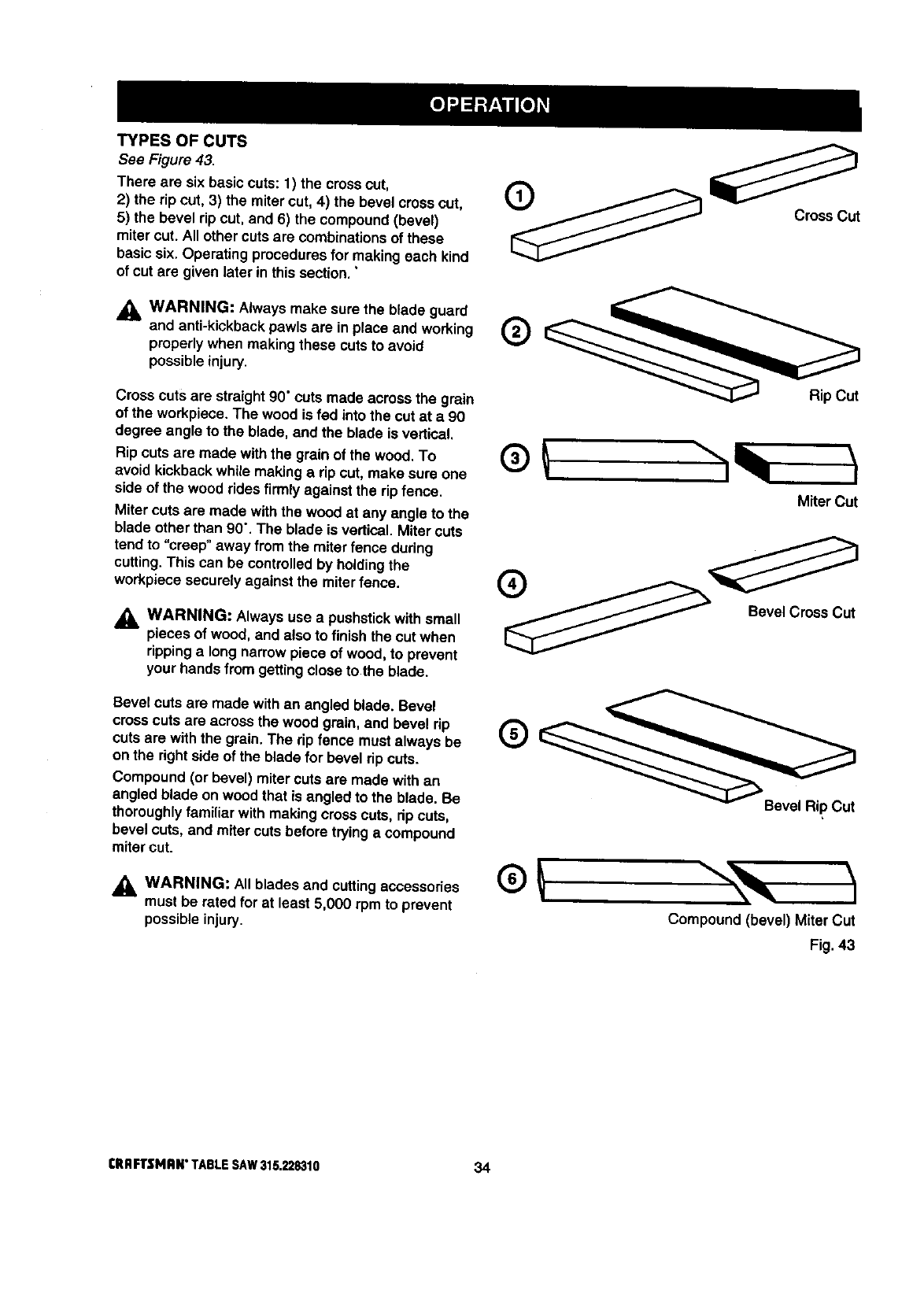

TYPES OF CUTS

See Figure 43.

There are sixbasic cuts: t ) the crosscut,

2) the ripcut, 3) the mitercut, 4) the bevel crosscut,

5) the bevel rip cut, and 6) the compound(bevel)

miter cut. Allother cuts are combinations of these

basicsix. Operating proceduresfor making each kind

of cutare given later in this sect'lon."

_. WARNING: Always make sure the blade guard

and anti-kickbackpawls are in place and working

properlywhen making these cuts toavoid

possibleinjury.

Cross cuts are straight90" cutsmade across the grain

ofthe workpiece. The wood is fed intothe cut at a 90

degree angle tothe blade, and the blade isvertical,

Ripcuts are made withthe grain of the wood. To

avoid kickbackwhile makinga rip cut, make sure one

side of the woodrides firmly against the rip fence.

Mitercuts are made withthe wood at any angle to the

bladeother than 90". The blade is vertical. Miter cuts

tend to "creep" away from the miter fence during

cutting.This can be controlledbyholdingthe

workpiece securelyagainst the miterfence.

_, WARNING: Always use a pushstickwith small

pieces of wood, and also tofinish the cut when

rippinga longnarrowpiece ofwood, to prevent

your handsfrom gettingcloseto the blade.

Bevel cuts are made with an angled blade. Bevel

crosscuts are across the wood grain, and bevel rip

cuts are with the grain.The ripfence must always be

on the rightside ofthe blade for bevel rip cuts.

Compound (or bevel) miter cutsare made with an

angled blade on woodthat is angled tothe blade. Be

thoroughlyfamiliar with making cross cuts, dp cuts,

bevel cuts, and miter cutsbefore tryinga compound

mitercut.

_, WARNING: All blades and cuttingaccessodes

mustbe rated for at least 5,000 rpm to prevent

possibleinjury.

CrossCut

®

MiterCut

o

Bevel Cross Cut

Bevel Rip Cut

Compound (bevel) Miter Cut

Fig. 43

tRRFTSNRN"TABLESAW315.228310 34