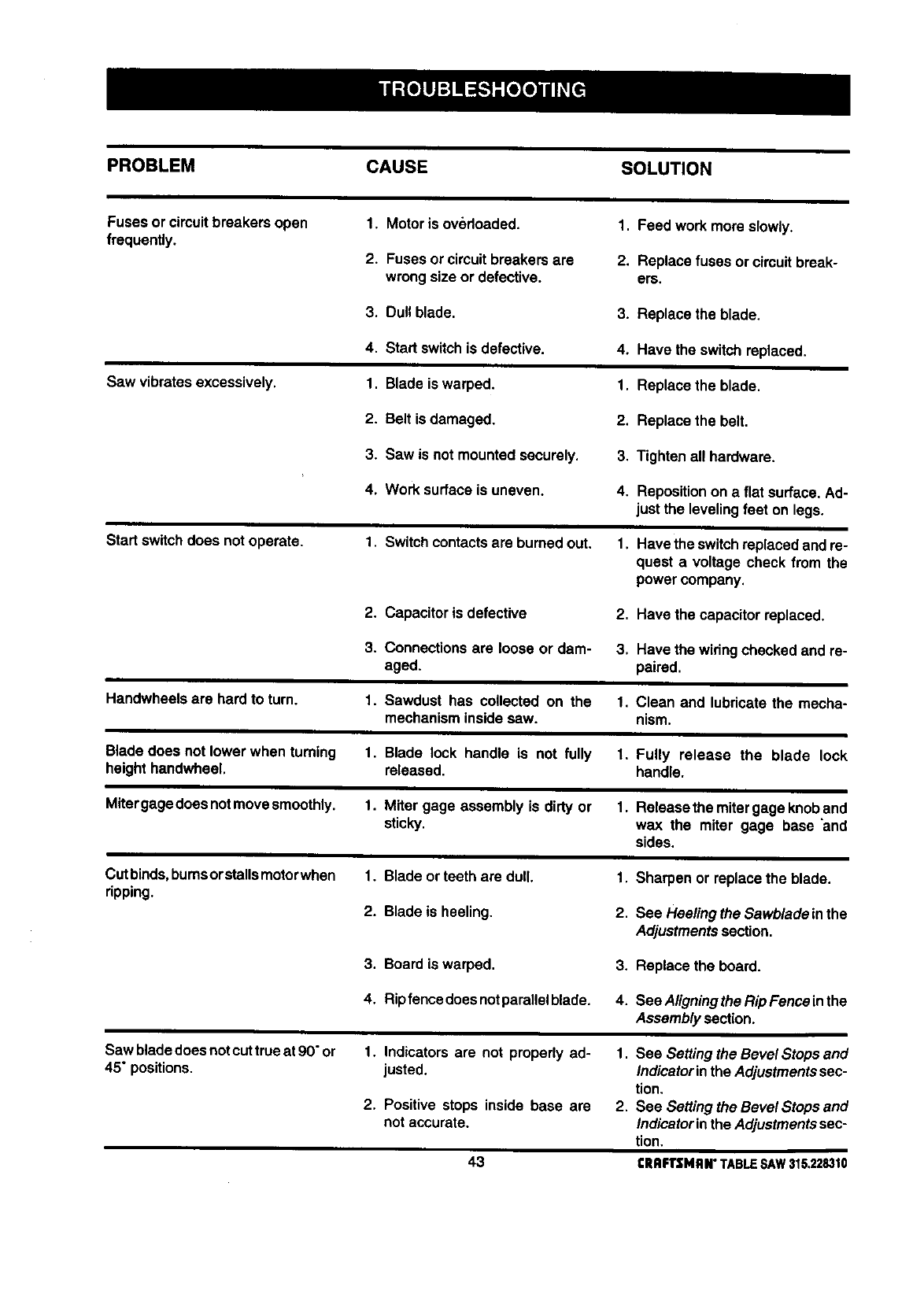

PROBLEM CAUSE SOLUTION

Fuses or circuitbreakers open

frequently.

1. Motor isoverloaded.

2. Fuses or circuitbreakersare

wrongsize or defective.

1. Feed work more slowly.

2. Replace fuses or circuit break-

ers,

3. Dull blade. 3. Replace theblade.

Saw vibratesexcessively.

4. Startswitchis defective.

1. Blade iswarped.

4. Have the switchreplaced.

1. Replacethe blade.

2. Belt isdamaged,

2. Replacethe belt.

3. Saw is not mountedsecurely. 3, Tighten all hardware.

4. Work surface isuneven.

4. Repositionon a flat surface.Ad-

justthe leveling feet on legs.

Start switchdoes not operate.

1. Switch contactsare burned out. 1. Havetheswitchreplaced andre-

quest a voltage check from the

powercompany.

2. Capacitoris defective

2. Havethe capacitor replaced.

3. Connectionsare loose or dam- 3. Havethe widngchecked and re-

aged. paired.

Handwheelsare hard to turn.

1. Sawdust has collected on the 1. Clean and lubricatethe mecha-

mechanisminsidesaw. nism.

Bladedoes not lowerwhen turning

heighthandwheel.

1. Blade lock handle is not fully 1. Fully release the blade lock

released, handle.

Mitergagedoesnotmovesmoothly.

1. Miter gage assembly is dirty or 1. Release themitergage knoband

sticky, wax the miter gage base _and

sides.

Cutbinds,bumsorstallsmotorwhen

ripping.

1. Blade orteeth are dull,

2. Blade isheeling.

1. Sharpen or replacethe blade.

2. See Hee/ingtheSawbladeinthe

Adjustmentssection.

3. Board iswarped. 3. Replace the board.

4. Ripfencedoesnotparallelblade. 4. SeeAligningtheRipFenceinthe

Assemblysection.

Saw bladedoes notcut trueat90"or 1.

45" positions.

2.

Indicators are not properly ad-

justed.

Positive stops inside base are

notaccurate.

1. See SettingtheBevel Stops and

Indicatorinthe Adjustmentssec-

tion.

2. See Setting theBevel Stops and

Indicatorinthe Adjustmentssec-

tion.

43 CRAFTSMRN"TABLESAW315.228310