Setup

Connect Press

ure Relief Lines

Do not operate Reactor without all covers and

shrouds in place.

1. Recommended: Connect high pressure

hose (R) to relief fittings (BA, BB) of both

PRESSURE RELIEF/SPRAY valves. Route

hose back to component A and B drums. See

Typical Installation, with circulation, page 13.

2. Alternately: Secure supplied bleed tubes (N)

in grounded, sealed waste containers (H). See

Typical Installation, without circulation, page 14.

Install Fluid Temperature Sensor

The Fluid Temperature Sensor (FTS) is supplied.

Install FTS between main hose and whip hose. See

Heated Hose manual for instructions.

Connect Heated Hose

See Heated Hose manual for detailed instructions on

connecting heated hoses.

Note

The FTS (C) and whip hose (D) must be used

with heated hose. Hose length, including

whip hose, must be 60 ft (18.3 m) minimum.

NOTICE

Apply grease on all system and hose fluid fittings.

This lubricates the threads and prevents material

from hardening on the threads.

1. Turn main power switch OFF .

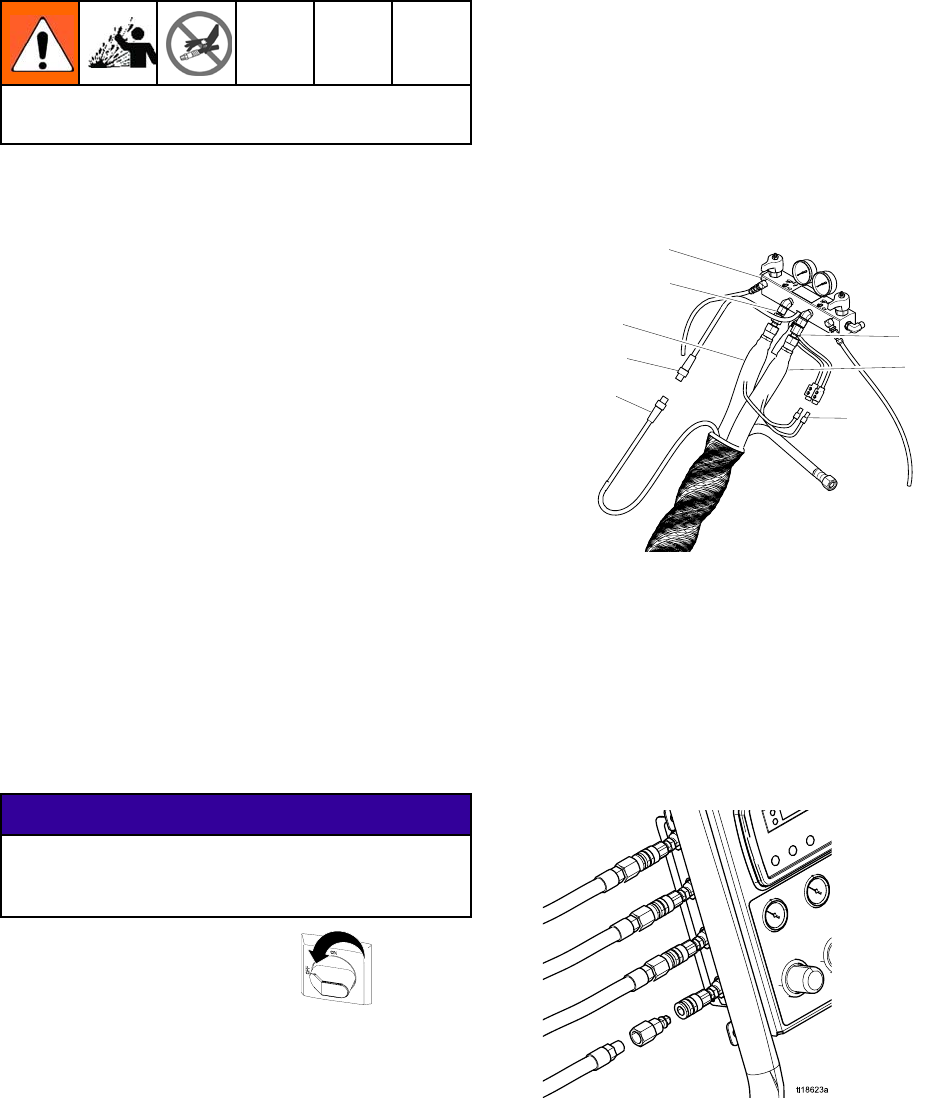

2. Assemble heated hose sections, FTS, and whip

hose.

3. Connect A and B hoses to A and B outlets on

Reactor fluid manifold (FM). Hoses are color

coded: red for component A (ISO), blue for

component B (RES). Fittings are sized to prevent

connection errors.

Note

Manifold hose adapters (HA, HB) allow

use of 1/4 in. and 3/8 in. ID fluid hoses.

To use 1/2 in. (13 mm) ID fluid hoses,

remove adapters from fluid manifold and

install as needed to connect whip hose.

FM

HA

A

V

B

HB

C

SC

Figure 32

4. Connect cables (C). Connect electrical

connectors (V). Be sure cables have slack

when hose bends. Wrap cable and electrical

connections with electrical tape.

5. Connect quick-disconnect pin fitting to 4 ft air

hose, shipped loose. Connect other hose end to

the gun air hose in the heated hose bundle. Push

pin fitting into the lowest air panel outlet (PJ).

Figure 33

40 3A1705J