Maintenance

6. To drain engine coolant loop:

a. Remove the eng

ine coolant loop (RC) cap.

b. Remove engine

guards as shown. Let the

guards rest on

theenginetoaccessthedrain

valve.

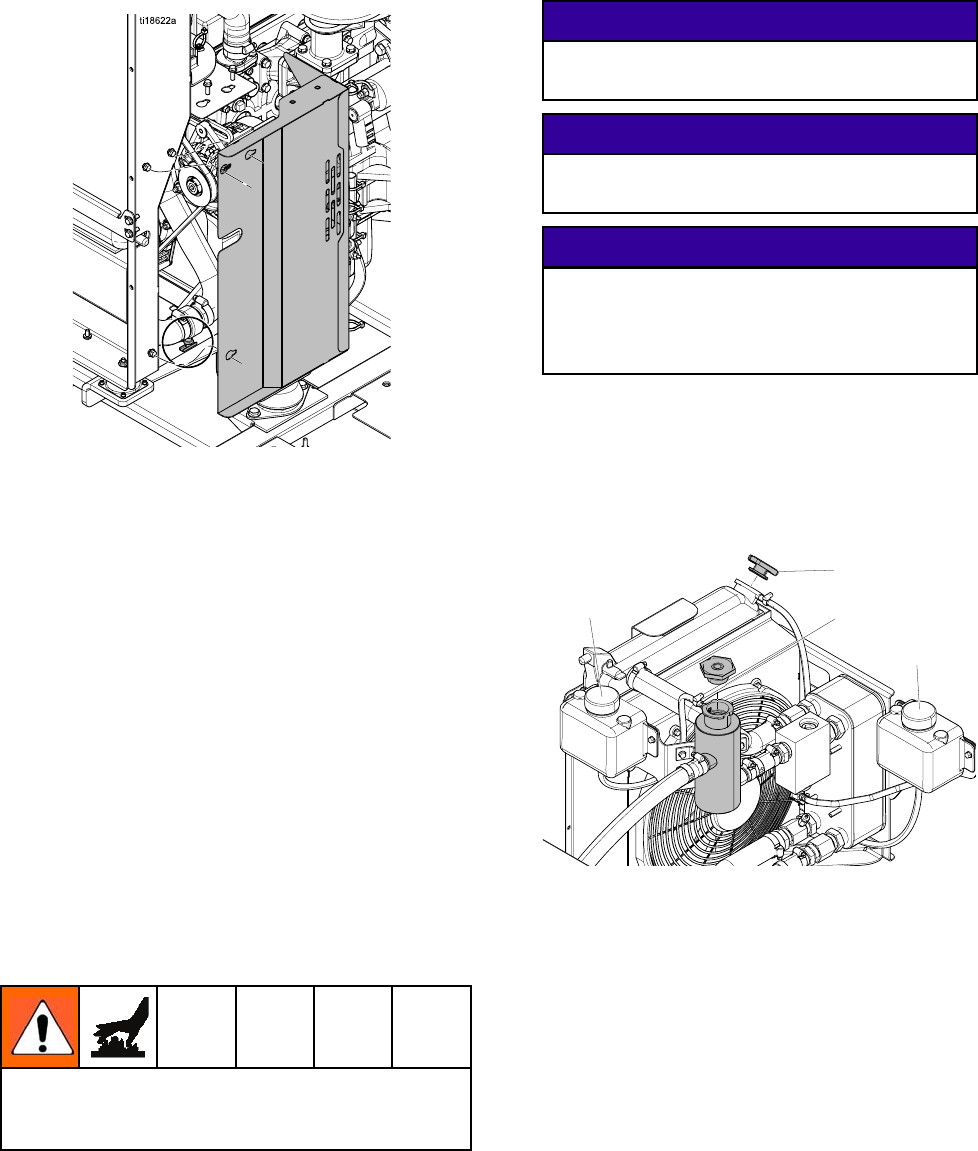

Engine Coolant Loop Drain Valve

Figure 43

c. Place a waste container under the drain

valve. Open the drain valve and drain

coolant.

d. To refill coolant loop, see

Refill Engine Coolant Loop, page 72.

e. Replace engine shrouds. Torque screws to

25 ft-lbs (33.8 N∙m)

Refill Proportioner Coolant Loop

Note

Air needs to be purged from the proportioner

coolant loop when it is filled with new coolant

or when air enters the coolant system. It

takes about one full warm-up and cool-down

cycle to purge air from coolant.

To

avoid burns, do not perform maintenance on

th

e coolant system until the coolant system has

re

ached ambient temperature.

Only use coolant solutions that are compatible with

the system. See Coolant Specifications, page 72.

1. Before refilli

ng coolant loop, perform steps 1–3

from Drain Coo

lant, page 69. Drain coolant loop

if necessary.

NOTICE

Do not refill with drained coolant. Use only

fresh, new coolant to avoid contaminants.

NOTICE

Do not use any “stop leak” additives to prevent

plugged filters and small orifices.

NOTICE

Do not inte

rchange the two caps between

the radiat

or and coolant bottle. The caps

have diff

erent pressure ratings that affect the

overflow.

2. Remove the caps from the metal proportioner

coolant loop fill bottle (HF) and expansion

bottle (HB). Fill the proportioner coolant loop fill

bottle (HF) to the top and add more coolant to

expansion bottle (HB) until the coolant is at the

cold fill line. See Coolant Specifications, page 72.

EB

HF

HB

RC

Coolant System Bottles

Figure 44

70 3A1705J