Startup

Startup

To prevent serious injury, only operate Reactor

with all covers and shrouds in place.

NOTICE

Proper system setup, startup, and shutdown

procedures are critical to electrical equipment

reliability. The following procedures ensure steady

voltage. Failure to follow these procedures will

cause voltage fluctuations that can damage

electrical equipment and void the warranty.

1. Check generator fuel level.

Running out of fuel will cause voltage fluctuations

that can damage electrical equipment.

2. Check coolant levels.

Inspect the level of coolant inside the engine

coolant expansion bottle (EB) and heat

exchanger coolant expansion bottle (HB).

COLD

HOT

COLD

HOT

3. Check fluid inlet screens.

Before daily startup, ensure that the

fluid inlet screens are clean. See

Flush Inlet Strainer Screen, page 67

4. Check ISO lubrication reservoir.

Check level and condition of ISO lube daily. See

Pump Lubrication System, page 68.

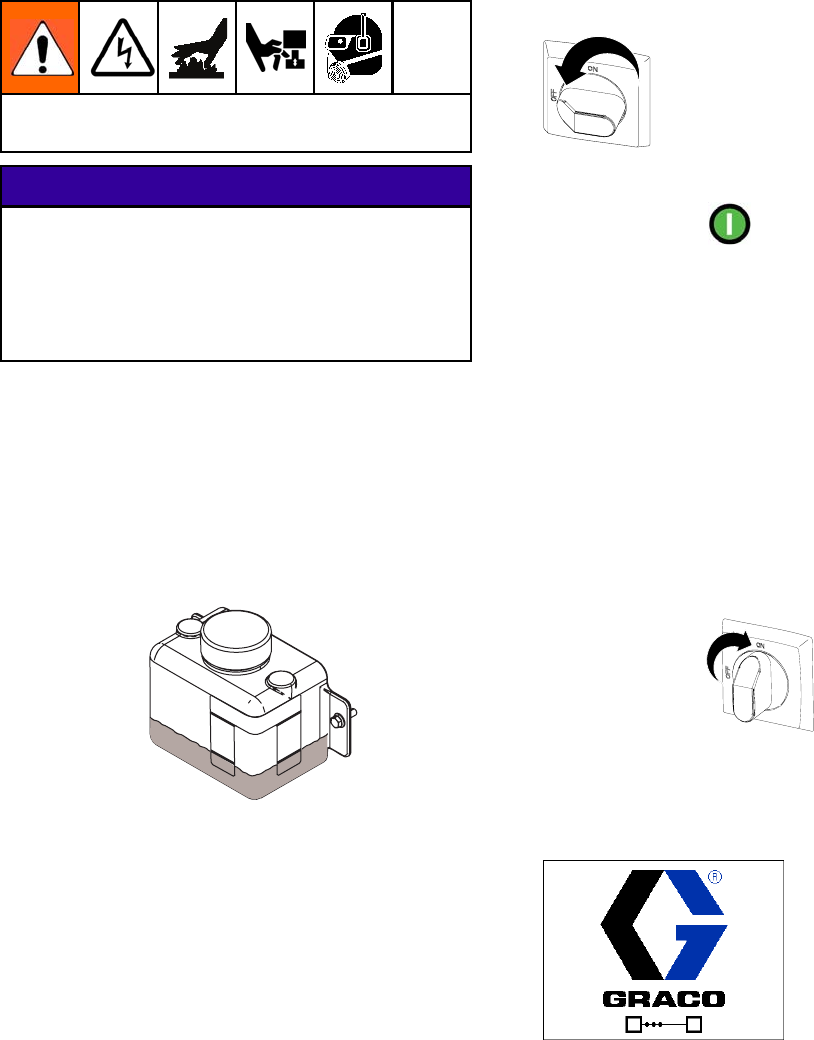

5. Confirm main power switch is OFF before starting

generator.

6. Start the generator.

Press start button

twice on the engine

control module. The controller will automatically

sequence glow plug warming and crank

operations. Allow engine to reach full operating

speed.

Note

Engine will not start if main power switch

is in the on position.

Note

If the engine control module screen

does not light up after the start button is

pressed, see the system repair manual.

7. Turn main power switch ON.

When the system is powered up by turning the

main power switch (MP) to the ON position, the

splash screen will display until communication

and initialization is complete.

3A1705J 55