Maintenance

Drain Coolant

To avoid burns, do not perform maintenance on

the coolant system until the coolant system has

reached ambient temperature.

Drain coolant from the engine and proportioner

coolant loops once a year or if the coolant lines need

to be disconnected, in order to install a wall between

the generator and proportioner.

1. Perform Shutdown, page 63.

2. Remove the cabinet door from the front of the

proportioner.

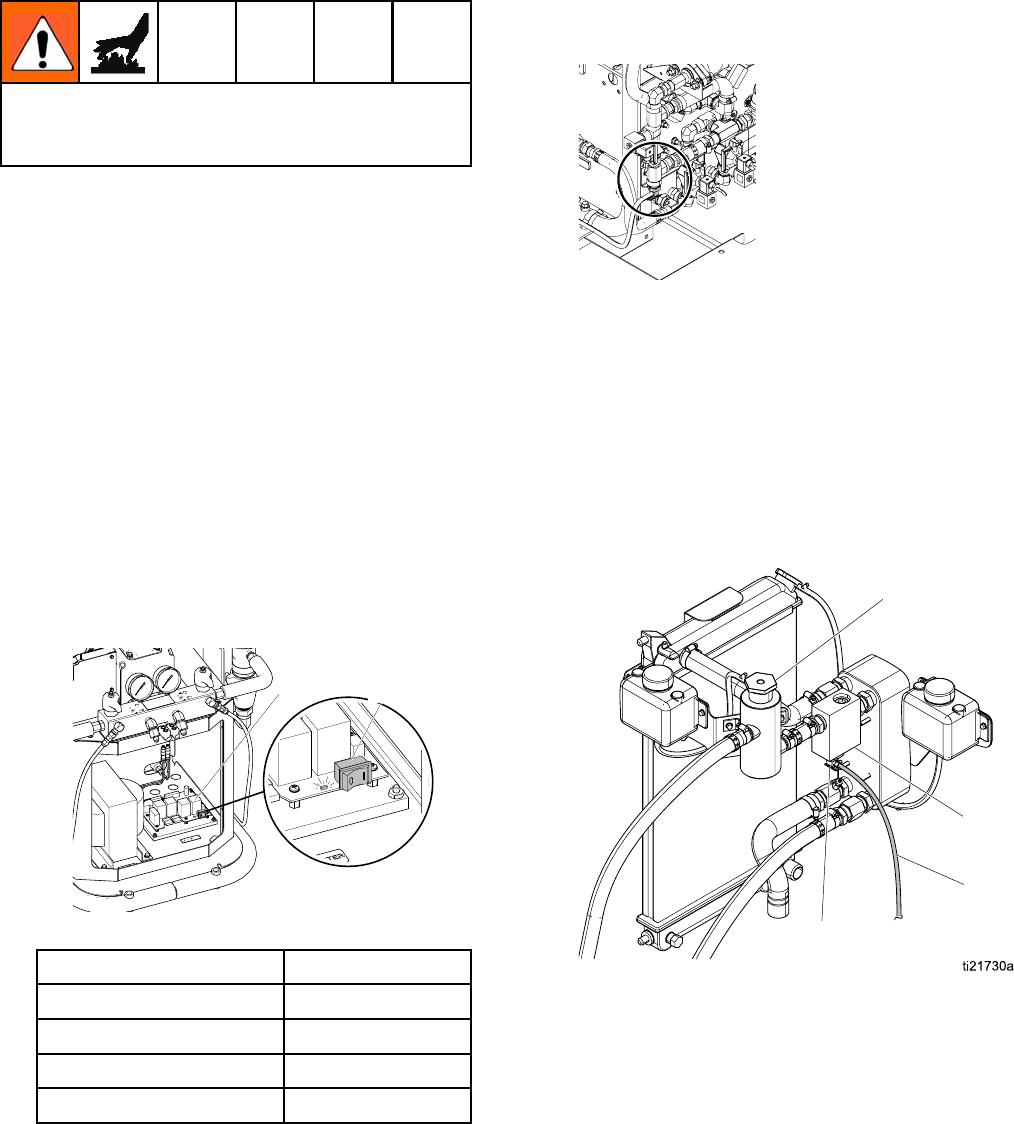

3. Turn on manual valve switch (MV), located on

the load center (LC), to manually open the A

and B heat exchanger control valves and bypass

control valve.

Note

The battery must be connected to

operate valves. The load center (LC)

LEDs will stay on when the manual valve

switch (MV) is in the ON position.

LC

MV

Figure 40

LED Component LED Color

Manualvalveswitch(MV)

Red

A Side Control Valve

Red

B Side Control Valve

Blue

Bypass Valve

Green

4. To drain proportioner coolant loop:

a. Remove the proportioner coolant loop fill

bottle (HF) cap.

b. Place the other end of the drain tube in a

waste container. Open the drain valve. Drain

coolant until coolant is no longer visible in

the sight glass.

Proportioner Coolant Loop Drain Valve

Figure 41

c. To refill coolant loop, see

Refill Proportioner Coolant Loop, page 70.

5. To drain proportioner coolant loop from filter

housing. Only available on Series B systems.

a. Remove the proportioner coolant loop fill

bottle cap (HF).

D

H

T

HF

Filter Housing Drain Valve (D)

Figure 42

b. Place the other end of the filter housing drain

tube (T) in a waste container. Open the drain

valve (D).

c. To refill coolant loop, see

Refill Engine Coolant Loop, page 72.

3A1705J 69