Maintenance

Engine Maintenance

The engine ins

tructions that accompany your

unit detail sp

ecific procedures for maintenance of

the engine. Fo

llowing the engine manufacturer’s

recommendati

ons will extend engine work life.

Daily

• Cooling System Coolant Level — Check

• Engine Air Cleaner Service Indicator — Inspect

• Engine Oil Level — Check

Every 500 Se

rvice Hours or 1 Year

• Engine Air Cleaner Element (Dual Element) —

Clean/Replace

• Engine Oil and Filter — Change

• Fuel System Filter — Replace

• Battery Voltage — Check. See

Appendix A: Engine Control Module, page 93.

Contact an Authorized Perkins Dealer or Distributor

for replacement filter elements. Refer to Perkins

engine part number GN66141N for compatible parts.

Fuel Tan

k

Fuel quality is critical to the performance and to the

service life of the engine. Water in the fuel tank

can cause excessive wear to the fuel system. See

the supplied Perkins engine manual for fuel tank

maintenance recommendations.

Flush

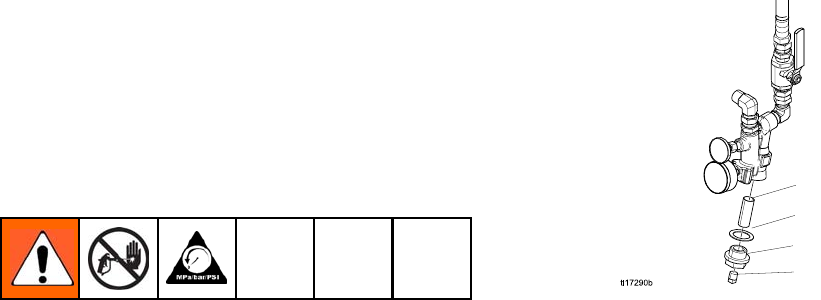

Inlet Strainer Screen

The inlet strainers filter out particles that can plug the

pump inlet check valves. Inspect the screens daily as

part of the startup routine, and clean as required.

Isocyanate can crystallize from moisture

contamination or from freezing. If the chemicals used

are clean and proper storage, transfer, and operating

procedures are followed, there should be minimal

contamination of the A-side screen.

Note

Clean the A-si

de screen only during

daily startup

. This minimizes moisture

contaminatio

n by immediately flushing

out any isocya

nate residue at the start of

dispensing op

erations.

1. Close the fluid inlet valve at the pump inlet and

shut off the appropriate feed pump. This prevents

material from being pumped while cleaning the

screen.

2. Place a container under the strainer base to catch

drain off when removing the strainer plug (C).

3. Remove the screen (A) from the strainer

manifold. Thoroughly flush the screen with

compatible solvent and shake it dry. Inspect the

screen. No more than 25% of the mesh should

be restricted. If more than 25% of the mesh is

blocked, replace the screen. Inspect the gasket

(B) and replace as required.

4. Ensurethepipeplug(D)isscrewedintothe

strainer plug (C). Install the strainer plug with the

screen (A) and gasket (B) in place and tighten.

Do not overtighten. Let the gasket make the seal.

5. Open the fluid inlet valve, ensure that there are

no leaks, and wipe the equipment clean. Proceed

with operation.

A

B

C

D

Figure 38

3A1705J 67