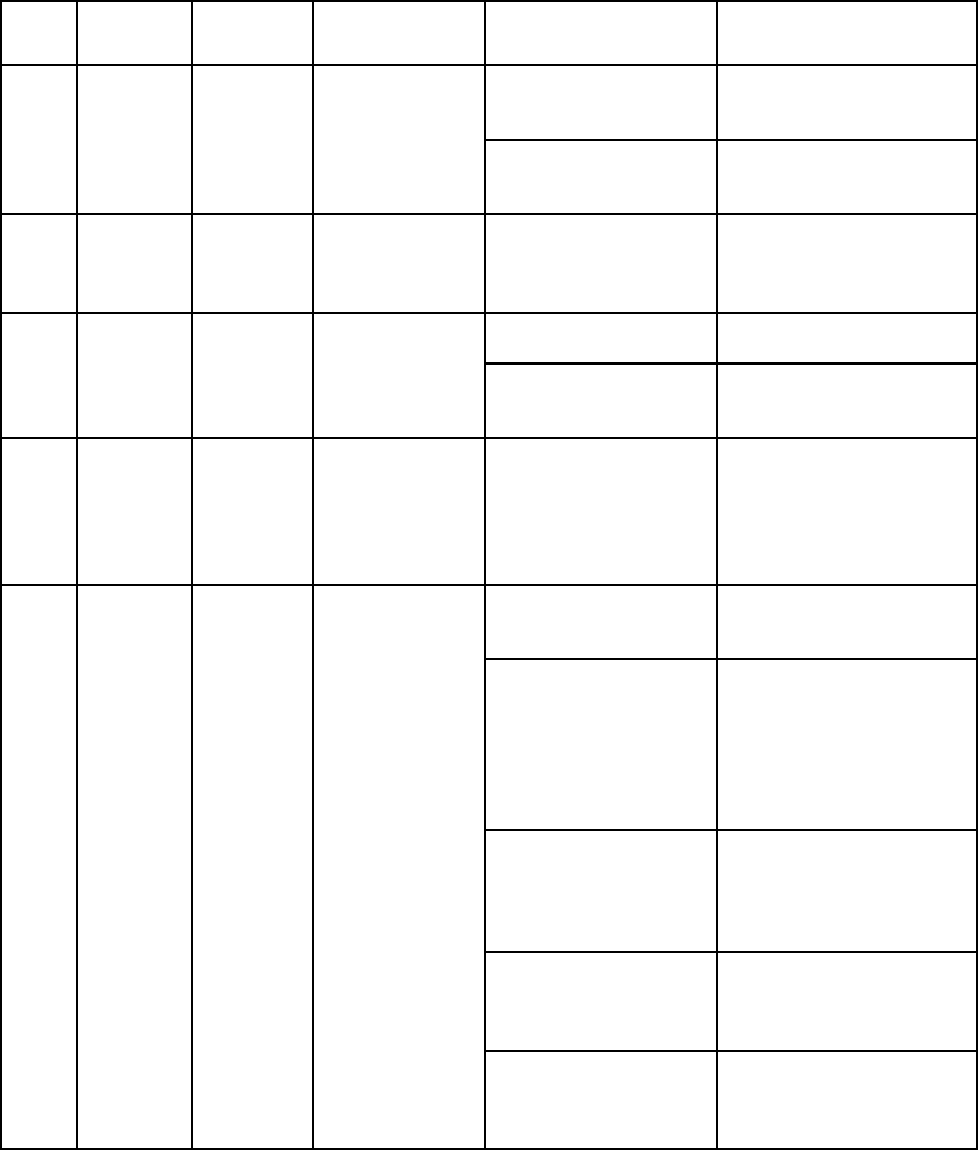

Troubleshootin

g

Error

Code

Error

Position

Type Name

Cause Solution

Flow is too high at current

setpoint.

Use a smaller mix chamber

that is rated for the unit in

use.

T2DA

T2DB

Boost A

Boost B

ALARM

Low Chemical

Temperature

Bad heater(s

)

Confirm resis

tance of heater

is 23–26.5 oh

ms. Replace if

OL/open loop

.

T2DH Hose ALARM

Low Chemical

Temperature

Cold chemical in

unheated portion of

system passed hose FTS

at startup.

Recirculate

heated chemical

back to drum

in cold

conditions

before startup.

Radiator fan will not stop. Replace fan relay. See

system repair manual.

T2DE Heat

Exchanger

ADVISORY

Low Temperature

Coolant Outlet

Engine thermostat is

stuck open.

Replace t

hermostat. See

Perkins d

istributor to

replace.

T3NM

MCM ADVISORY

High Mot

or

Tempera

ture

Motor is

operating

outside

of pressure

flow curv

e. The system

is runni

ng at a lower

setpoin

ttopreserve

motor l

ife.

Run the s

ystem at a

lower du

ty cycle or with a

smaller

mix chamber. See

Perform

ance Charts, page

99.

Manual valve switch (MV)

on load center board is in

the ON position.

Open cabinet cover and turn

switch to the OFF position.

A or B side control valve

solenoid is stuck in the

open position. Debris

in valve diaphragm

or plunger preventing

spring-loaded closed

function.

Disconnect connector

from valve solenoid coil.

If temperature does not

decrease, rebuild solenoid.

Shortonloadcenter

board. If the blue and red

LEDsareonwhilethe

heat is off, then the load

center board is bad.

See Load Center

Diagnostics in the system

repair manual.

(T

4BE only) J6 connector

on

load center “Heat

Va

lves” location is not

ce

ntered.

Reconnect J6 connector

on load center in centered

location.

T4AE

T4BE

Heat

Exchan

ger

ALARM

High Chemical

Temperature Hx A

(T4AE)

High Chemical

Temperature Hx B

(T4BE)

A

and B heat

e

xchanger RTD cables

c

ross-connected to

s

plitter cable.

See System Repair Manual

for correct connection.

82 3A1705J