G0675 10" Jointer/Planer Combo Machine

-35-

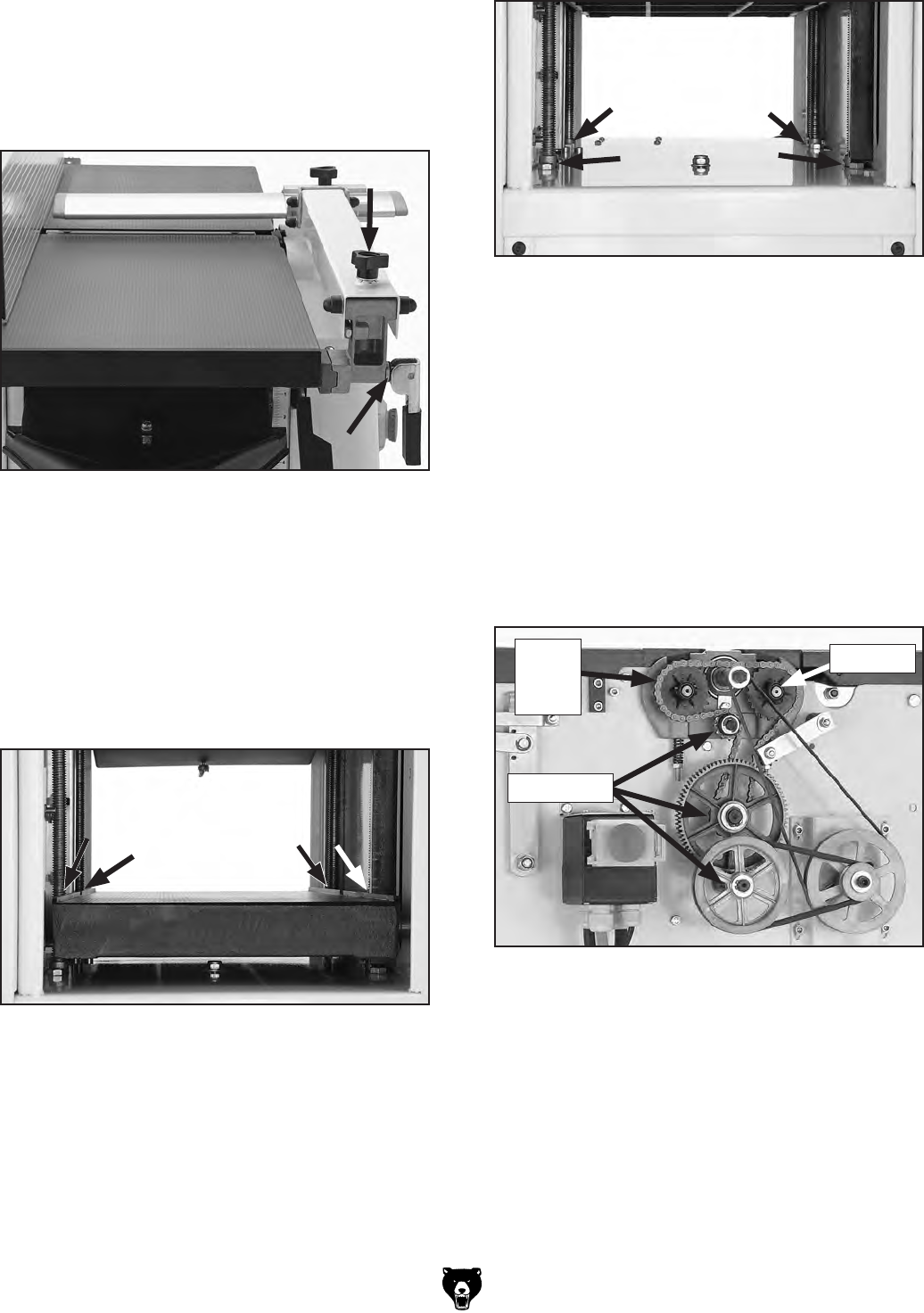

Figure 53. Feed roller chain, sprocket, and

cogwheel lubrication locations.

Cogwheels

Blade Guard Arm

Clean away any built up grime and debris with a

rag and mineral spirits, then place 1-2 drops of

light machine oil on the points shown in Figure

50 once a month.

Figure 50. Blade guard arm lubrication locations.

Feed Roller Chain, Sprocket and

Cogwheels

Inspect the feed roller chain and feed roller

sprockets monthly. Thoroughly clean debris and

grime with a rag and mineral spirits, then use a

brush or rag to apply a thin coat of multi-purpose

grease when needed, as shown in Figure 53.

Remove the front panel to access.

Lubricate the cogwheels with a thin coat of multi-

purpose grease every 40 operating hours.

Figure 52. Additional leadscrew lubrication

locations.

Leadscrews

Clean away debris and built-up grime on the lead-

screws with a rag and mineral spirits, then apply a

thin coat of SAE 10-30W oil with a clean rag to the

four leadscrews in the locations shown in Figures

51–52 after the first five hours and then every 20

hours. Move the planer table through its full range

of motion to distribute the lubricant.

Figure 51. Leadscrew-planer table lubrication

locations.

Photo Note: Show both sides like figure below.

Sprocket

Feed

Roller

Chain