G0675 10" Jointer/Planer Combo Machine

-51-

7. Locate the chain on the underside of the

table.

8. Loosen the idler sprocket (see Chain Tension

instructions on Page 48).

9. Mark the location of one tooth in the sprocket

that you are adjusting.

10. Move the chain away from only the sprocket

you want to adjust so only that sprocket can

be turned independent of the chain.

Note: If the left side of the table is too high

(viewed from the planer table infeed), the

front and rear left sprockets will need to be

adjusted. Each tooth on the sprocket rep-

resents .007" of vertical movement as the

cogs are turned. Make sure, as you turn the

sprockets, to keep an accurate tooth count to

ensure that the table is adjusted equally.

11. Carefully turn the sprocket (clockwise to

lower the table; counterclockwise to raise the

table) just enough to position the next tooth at

the marked location, then fit the chain around

sprocket again.

12. Repeat Steps 9–11 with each sprocket that

needs to be adjusted until the table-to-cutter-

head clearance is within 0.007" from one side

to the other.

13. Make sure the chain is properly fitted on the

sprockets, and tighten the idler sprocket lock

nuts.

14. Place the table back on the base with the

forklift, relatch the base to the jointer/planer,

and reinstall the access panels.

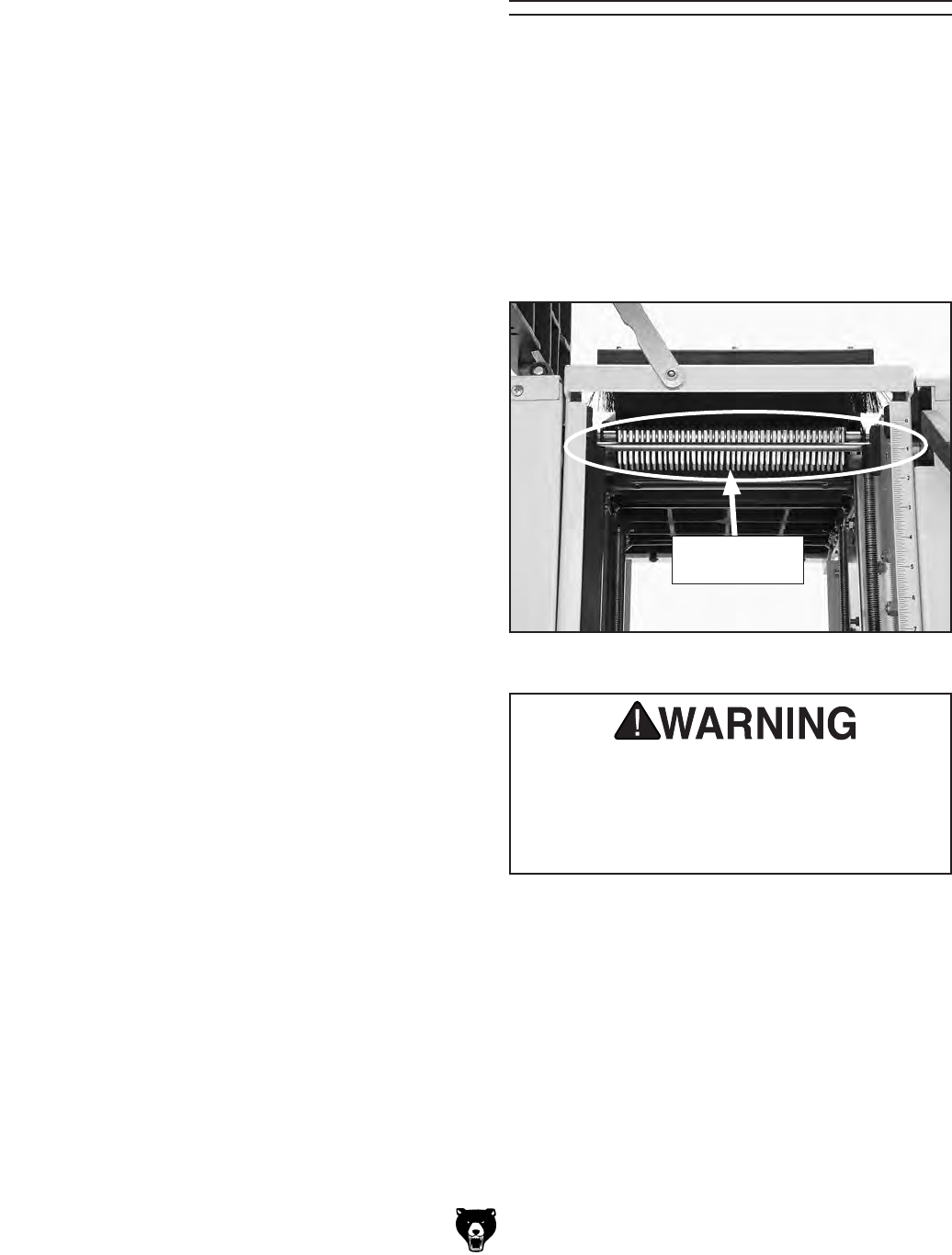

Anti-Kickback

Fingers

The Model G0675 provides an anti-kickback sys-

tem as a safety feature. The anti-kickback fingers

hang from a rod suspended across the cutterhead

casting. The anti-kickback fingers should be

inspected regularly.

Check the fingers (Figure 85) to ensure that they

swing freely and easily. If the fingers do not swing

freely and easily, clean them with a wood resin

solvent.

Do not apply oil or other lubricants to the anti-

kickback fingers. Oil or grease will attract dust,

restricting the free movement of the fingers.

Figure 85. Anti-kickback fingers.

Anti-Kickback

Fingers

Proper operation of the anti-kickback fin-

gers is essential for the safe operation of

this machine. Failure to ensure that they

are working properly could result in serious

operator injury.