A-15

INSTALLATION

POWER WAVE® AC/DC 1000

A-15

ELECTRODE AND WORK

CONNECTIONS

General Guidelines

The unique switching structure of the Power Wave

AC/DC 1000 allows it to produce DC positive, DC

negative or AC output waveforms without reposition-

ing the work and electrode leads. Additionally, no DIP

switch changes are required to switch between the dif-

ferent polarities. All of this is controlled internally by

the Power Wave AC/DC 1000, and based exclusively

on the weld mode selection.

The following recommendations apply to all output

polarities and weld modes:

• Select the appropriate size cables per the

"Output Cable Guidelines" below. Excessive volt-

age drops caused by undersized welding cables

and poor connections often result in unsatisfactory

welding performance. Always use the largest weld-

ing cables (electrode and work) that are practical,

and be sure all connections are clean and tight.

Note: Excessive heat in the weld circuit indicates

undersized cables and/or bad connections.

• Route all cables directly to the work and wire

feeder, avoid excessive lengths and do not coil

excess cable. Route the electrode and work cables

in close proximity to one another to minimize the

loop area and therefore the inductance of the weld

circuit.

• Always weld in a direction away from the work

(ground) connection.

TABLE A.1 - Output Cable Guidelines

Electrode Connections

Connect an electrode cable of sufficient size and

length (Per Table A.1) to the "electrode" stud on the

power source (located behind the cover plate on the

lower left side). For convenience, the cable can be

routed down through the two holes in the left cable

tray before being connected to the output terminals.

Connect the other end of the electrode cable to the

wire drive feed plate on the wire feeder. Be sure the

connection to the feed plate makes tight metal-to-

metal electrical contact.

For parallel applications with excessive electrode

cable lengths, a common bus connection should be

used. The common electrode connection serves to

minimize voltage drops associated with resistive loss-

es in the electrode path. It should be made of copper,

and located as close as possible to the power

sources. (See "Connection Diagram – Parallel

Machines")

Work Connections

Connect a work lead of sufficient size and length (Per

Table 1) between the "work" stud (located beneath the

spring loaded output cover on the top, front of the

machine) and the work piece. For convenience, the

work lead can be routed along the left cable tray, and

out the back of the machine. Be sure the connection

to the work makes tight metal-to-metal electrical con-

tact.

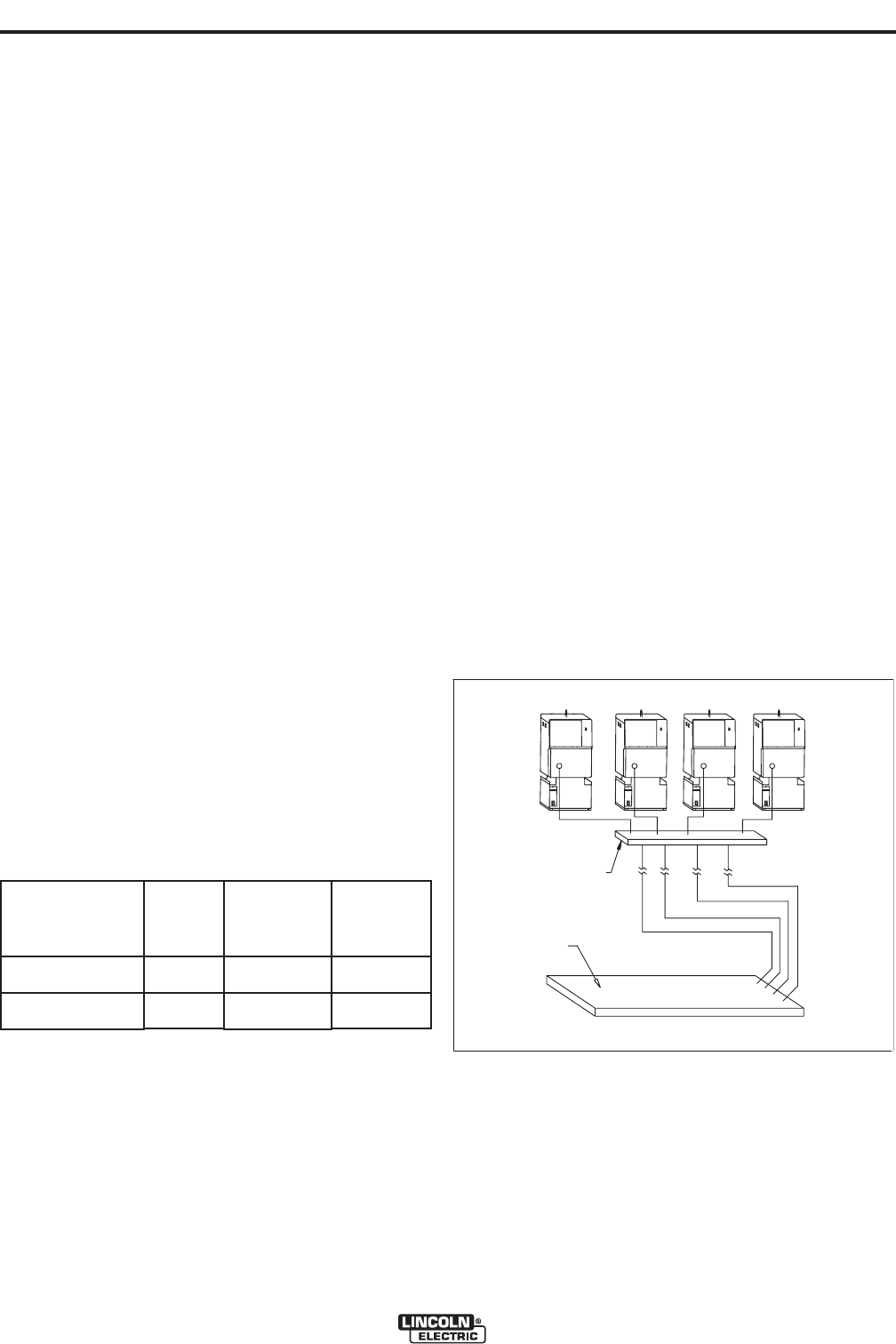

For parallel and/or multiple arc applications with

excessive ground path lengths, a common work con-

nection bus should be used. The common work con-

nection serves to minimize voltage drops associated

with resistive losses in the ground paths. It should be

made out of copper, and located as close as possible

to the power sources (See Common Connection

Diagram).

Total Cable Length

ft (m)

Electrode and Work

Combined

0 (0) to 250 (76.2)

0 (0) to 250 (76.2)

Duty Cycle

80%

100%

Number of

Parallel Cables

2

3

Cable Size

Copper

4/0 (120 mm

2

)

3/0 (95 mm

2

)

WORK PIECE

COMMON CONNECTION

(LOCATE

D

CLOSE TO

POWER SOUR

CES)

Common Connection Diagram