E-5

TROUBLESHOOTING

E-5

POWER WAVE® AC/DC 1000

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

Observe all Safety Guidelines detailed throughout this manual

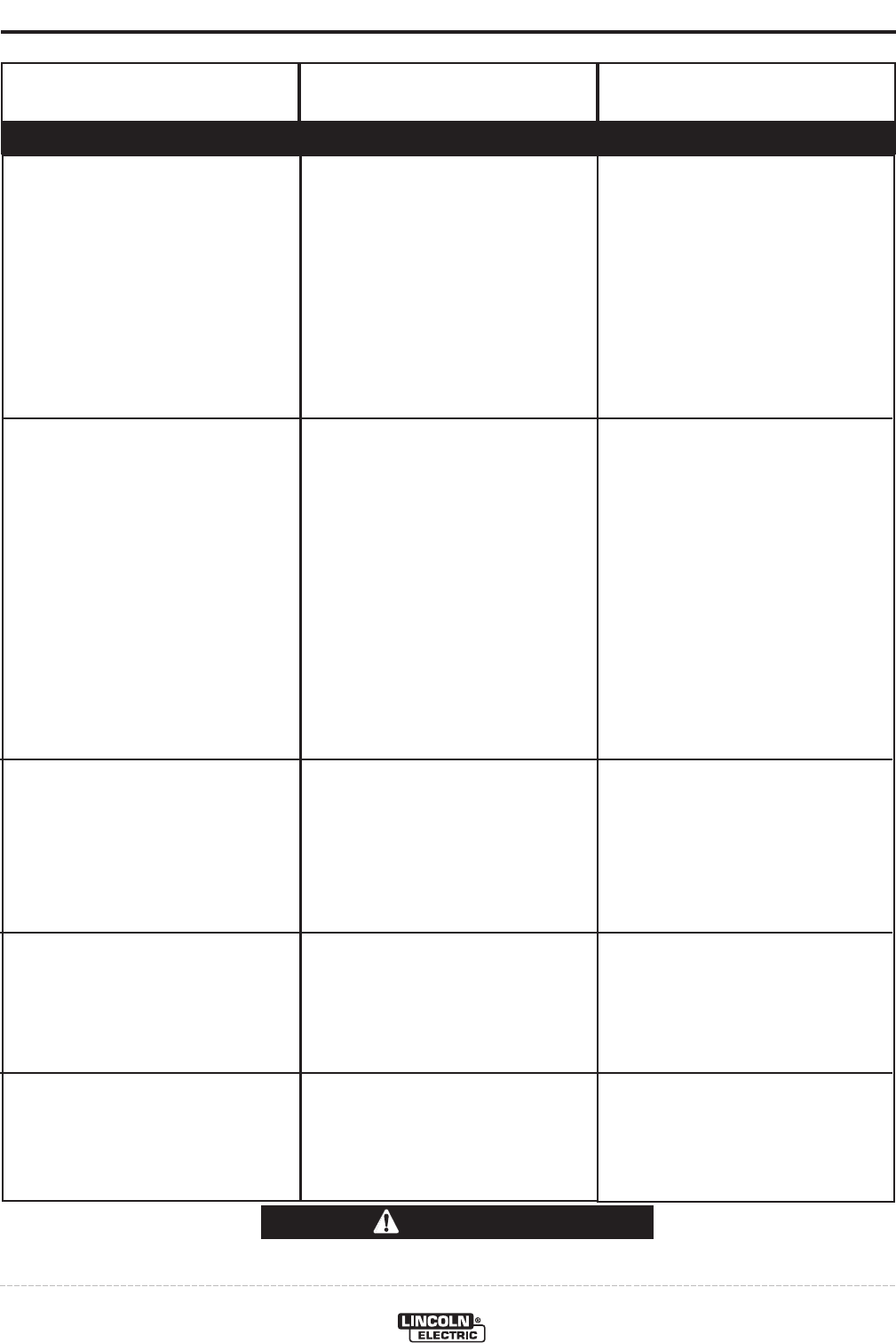

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Cannot weld AC.

Machine output shuts down during a

weld.

Machine won’t produce full output.

Excessively long and erratic arc.

1. Improper Ethernet I/O

Configuration.

2. AC Switch Problem.

1. Secondary current limit has been

exceeded, and the machine

shuts down to protect itself.

2. Single phase input (loss of L2).

3. Re-strike Time exceeded.

1. Input voltage may be too low,

limiting output capability of the

power source.

2. Machine calibration.

1. Voltage sensing problem.

2. Machine calibration.

1. Verify Ethernet board DIP Switch

settings.

2. If major physical or electrical

damage is evident when the

sheet metal cover is removed

from the AC Switch (lower sec-

tion of the machine).Contact your

local authorized Lincoln Electric

Field Service facility for technical

assistance.

1. Adjust procedure or reduce load

to lower current draw from the

machine.

2. Single phase input (loss of L2). A

single phase input (loss of L2)

will reduce the secondary current

limit and cause secondary over

current shutdown at lower output

levels. Check the input fuses and

supply lines.

3. Adjust the process parameters to

avoid excessive arc loss time or

increase the re-strike time.

1. Make certain that the input volt-

age is proper, according to the

Rating Plate located on the rear

of the machine.

2. Calibrate secondary current and

voltage.

1. Check for proper configuration

and implementation of voltage

sensing circuits.

2. Calibrate secondary current and

voltage.

WELD AND ARC QUALITY PROBLEMS