A-23

INSTALLATION

POWER WAVE® AC/DC 1000

A-23

WIRE DRIVE GEAR RATIO SETTING

Changing the wirefeeder gear ratio requires a gear

change in the wire drive, and a configuration change

at the power source. The Power Wave AC/DC 1000

can be configured to support up to 4 unique gear

ratios. The gear ratio configuration is selected via a

DIP switch on the Feed Head PC Board and a jumper

on the External I/O connector (S7 - located beneath

the spring loaded output cover on the top, front of the

machine).

As shipped from the factory, the low speed (high

torque) gear is installed. To change the gear ratio of

the feeder, see the Wirefeeder Instruction Manual. To

achieve the correct speed, the power source must

also be configured for the actual gear ratio installed in

the wire drive per the instructions below:

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrodes with your skin or wet

clothing.

• Insulate yourself from the work and

ground.

• Always wear dry insulating gloves.

-----------------------------------------------------------

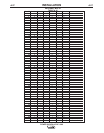

(See Figure A.3a)

1. Turn off power to the power source at the dis-

connect switch. All configuration changes must

be made with the power OFF.

2. Access the Feed Head board and External I/O con-

nector to configure the power source per table

A.9a.

3. Replace the cover and screws as required. The

Feed Head PC board will "read" the new configura-

tion at power up, and automatically adjust all control

parameters for the speed range selected.

WARNING

WARNING

S1S1

FEFEEEDHEDHEAADD

P.P.CC.. BOA BOARRDD

EXEXTTEERRNNAL I/OAL I/O

CCOONNNNEECTORCTOR

FIGURE A.3a

ETHERNET CONFIGURATION

Ethernet capability is provided for data monitoring, or

to enable parallel machine operation. To utilize these

features the network settings of each Power Wave

AC/DC 1000 must be properly configured. This is

accomplished through the use of the Weld Manager

software utility. Follow the instructions provided with

the utility to properly configure the Ethernet address.

When used in a system with parallel machines, the

Submerged Arc Cell Configuration software utility

must be used to map the master/slave relationships

within and between the different arc groups. This utili-

ty allows the user to configure the system by selecting

from a list of master and slave machines (as deter-

mined by their individual dip switch settings).

NOTE: Each machine must be configured as either a

Master or Slave via the dip switches on the

Ethernet PC Board. Furthermore, Master

machines must be configured for either inter-

nal synchronization (stand alone applica-

tions), or external synchronization (multiple

arc applications utilizing a Power Wave

System Interface). See the "Internal Controls"

section of this document.

Ratio

142:1

95:1

57:1*

Reserved*

(Presently57:1)

Dip Switch #8

(Feed Head PCB - Bank S1)

OFF

ON

OFF

ON

External I/O Jumper

(Pin 5 to Pin 12)

NO

NO

YES

YES

* These Gear Ratios options are enabled in

S25564-11 and later Feed Head software.

TABLE A.9a

1

2

3

4

5

6

7

8

9

10

11

12

JUMPER PIN 5

J

UMPER PIN 12