A-17

INSTALLATION

POWER WAVE® AC/DC 1000

A-17

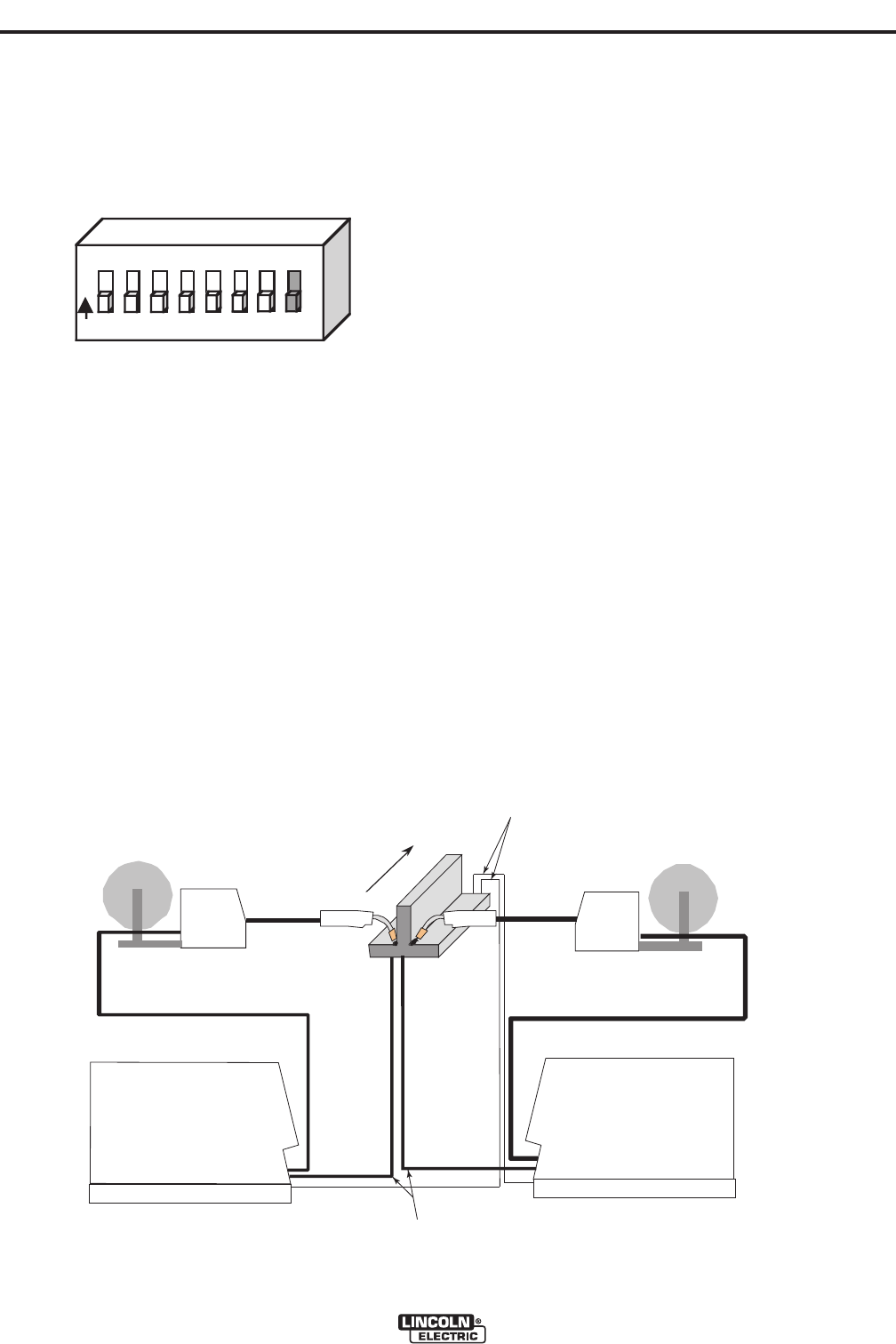

c. Locate the 8-position DIP switch on the control

board and look for switch 8 of the DIP switch.

d. Using a pencil or other small object, slide the

switch to the OFF position if the work sense lead

is NOT connected. Conversely, slide the switch

to the ON position if the work sense lead is pre-

sent.

e. Replace the cover and screws. The PC board will

read the switch at power up, and configure the work

voltage sense lead appropriately.

Voltage Sensing for "Slave" machines

If "Slave" machines are configured to use remote volt-

age sensing they receive these signals directly from

the "Master" machine. The K1795 control cable used

for parallel connection of machines contains both the

ELECTRODE sense lead (67) and the WORK sense

lead (21). No other external sense lead connections

are required for "Slave" machines.

NOTE: All of the machines of a given arc group

(both Master and Slaves) must have their

work voltage sensing configured identical-

ly. All must either use a remote lead or

sense directly from the stud. For addition-

al information see the "Work Voltage

Sensing" section of this document.

VOLTAGE SENSING CONSIDERATIONS FOR

MULTIPLE ARC SYSTEMS

Special care must be taken when more than one arc

is welding simultaneously on a single part. Multiple

arc applications do not necessarily dictate the use of

remote work voltage sense leads, but they are strong-

ly recommended.

If Sense Leads ARE NOT Used:

• Avoid common current paths. Current from adja-

cent arcs can induce voltage into each others cur-

rent paths that can be misinterpreted by the power

sources, and result in arc interference.

If Sense Leads ARE Used:

• Position the sense leads out of the path of the

weld current. Especially any current paths com-

mon to adjacent arcs. Current from adjacent arcs

can induce voltage into each others current paths

that can be misinterpreted by the power sources,

and result in arc interference.

• For longitudinal applications, connect all work

leads at one end of the weldment, and all of the

work voltage sense leads at the opposite end of the

weldment. Perform welding in the direction away

from the work leads and toward the sense leads.

(See Figure A.2)

1 2 3 4 5 6 7 8

O

N

DIRECTION

OF TRAVEL

CONNECT ALL

WORK LEADS AT

THE BEGINNING

OF THE WELD.

CONNECT ALL SENSE

LEADS AT THE END

OF THE WELD.

FIGURE A.2