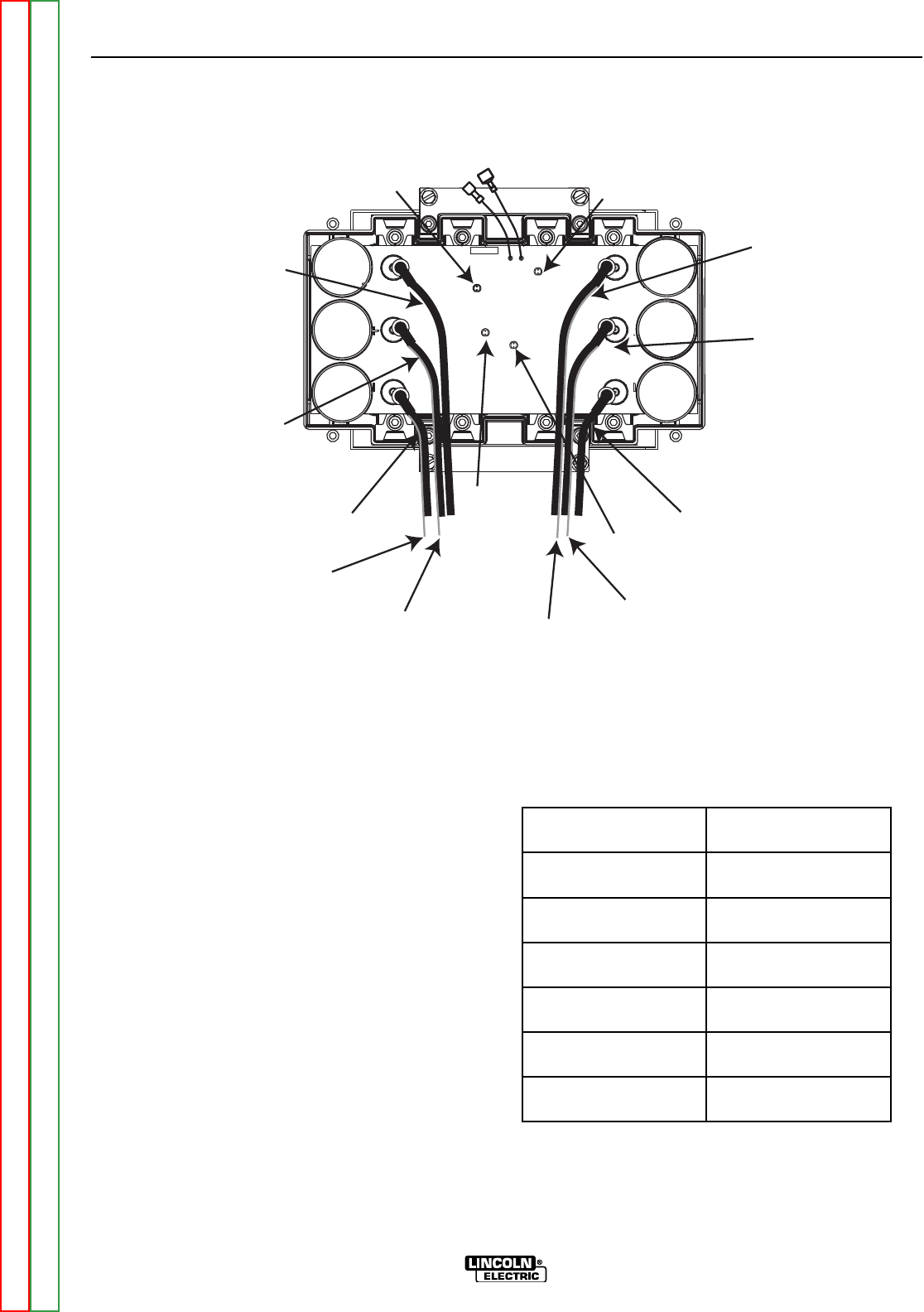

FIGURE F.18 - MODULE LEAD LOCATIONS

CHOPPER MODULE REMOVAL AND REPLACEMENT (CONTINUED)

PROCEDURE

REMOVAL

1. Turn the engine off.

2. Perform the Case Cover Removal

Procedure.

3. Perform the Chopper Module Capacitor

Discharge procedure.

4. Disconnect leads 23 and 25 at their in-line

couplings.

5. Using the 7/16” socket wrench, remove the fol-

lowing leads. Label the leads before removal.

Cut cable ties as needed. Note placement of

leads and fasteners: screw, lock washer, flat

washer, small lead, heavy lead.

6. Using a 3/8” socket wrench, remove the three

screws holding the power module assembly to

its brackets on the vertical baffle. Remove the

plastic strip with the top two screws. Be sure

to support the Power Module as you remove

the last screw.

7. Remove the Power Module assembly from the

machine.

TROUBLESHOOTING & REPAIR

F-92 F-92

VANTAGE® 400

B1

B2

B3

B6

B5

B4

23

25

SL302

SL301

HL W9

HL W4

HL W6

SL14

SL13

B8

HL W8

HL W5

HL W11

LED1LED1

LED4LED4

LED2LED2

LED3LED3

L12683-1

LED1 (B1,B2,B3)

Chopper Working

LED3 (B4,B5,B6)

Chopper Working

LED4

PWM Signal

LED2

Voltage from

Rectifier

TERMINAL LEADS

B4

Heavy lead W11,

Small lead 14

B5

Heavy lead W5,

Small lead 13

B6

Heavy lead W8

B1

Heavy lead W6

B2

Heavy lead W4,

Small lead 301

B3

Heavy lead W9,

Small lead 302

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC