G-2

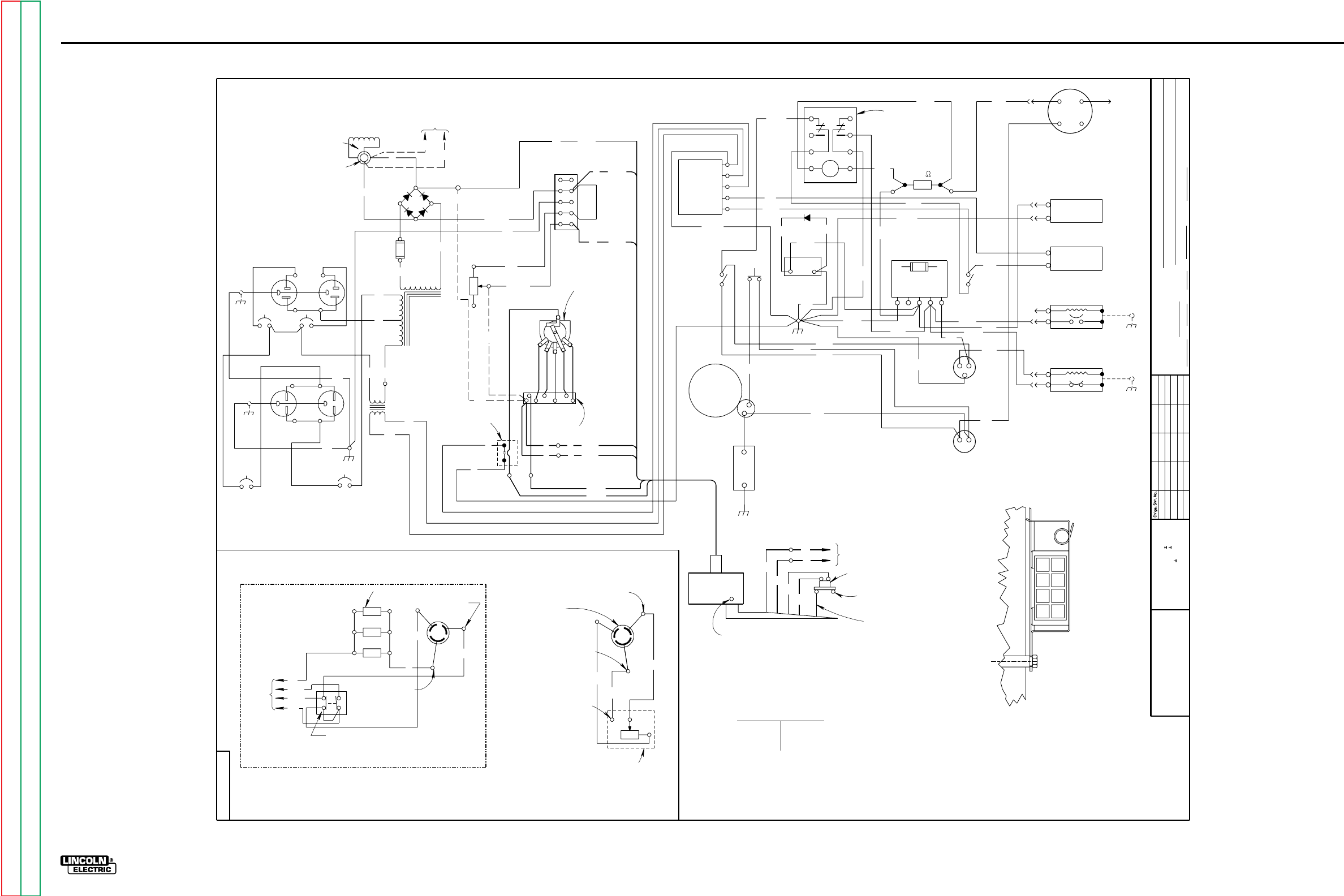

ELECTRICAL DIAGRAMS

CLASSIC II

Wiring Diagram (Code 9805 )

8594

5-1-92

CLASSIC II (WITH CV ADAPTER)

WIRING DIAGRAM

JE

NONE

8594

7-9-91

t

UNLESS OTHERWISE SPECIFIED TOLERANCE

ON HOLE SIZES PER E2056

ON 2 PLACE DECIMALS IS .02

WITH PUBLISHED STANDARDS.

ON 3 PLACE DECIMALS IS .002

ON ALL ANGLES IS .5 OF A DEGREE

MATERIAL TOLERANCE (" ") TO AGREE

THE LINCOLN ELECTRIC CO.

CLEVELAND, OHIO U.S.A.

EQUIP.

TYPE

SCALE

SUBJECT

DR

DATE

CHK

REF.

SUP'S'D'G

SHT.

NO.

THE LINCOLN ELECTRIC CO.

THIS SHEET CONTAINS PROPRIETARY INFORMATION

OWNED BY AND IS

NOT TO BE REPRODUCED, DISCLOSED OR USED

THE LINCOLN ELECTRIC CO.

L

L

WITHOUT THE EXPRESS PERMISSION OF

B

R

+

-

+

-

Y

R

W

BB

U

U

ALTERNATOR ROTOR

SLIP RINGS

SLIP RING NEAREST

TO IRON

R

N

A

54

3

2

1

ALTERNATOR

AUXILIARY

POWER

WINDINGS

CURRENT

TRANSFORMER

CB3

CB1

115 VOLT

RECEPTACLE

230 VOLT

RECEPTACLE

Y

N

U

Y

W

+

-

TO WELDING

GENERATOR

NEGATIVE

N

SELECTOR

SWITCH

WELDER

LEAD BLOCK

AC

AC

POTENTIOMETER

CR2 REED

RELAY

602

42

41

600

600A

41

42

602A

IDLER

P.C.

BOARD

U

U

R

W

Y

IGNITION

SWITCH

START

STARTING

MOTOR

-

+

ENGINE

HOUR METER

+

60D

53B

58B

57

56A

60

60A

7

9

A

B

CR1

59

53A

52

50A

51A

60C

60B

FUSE

(SFE-14)

D+

D-B+

W

21

56

IDLER

SWITCH

+

A

51

54B

50

TERMINAL

STRIP

GNONCS B

FUEL

SOLENOID

IDLER

SOLENOID

OIL TEMPERATURE

SENSOR

OIL PRESSURE

SENSOR

8

7

3

4

5

6

G

W

B

COPPER

TERMINAL

GROUND TERM.

(WIDE SLOT)

RESISTORS

SWITCH FOR

CONTROL SHOWN IN

LOCAL OR REMOTE

LOCAL POSITION.

SEE

BELOW

*

REMOTE CONTROL (OPTIONAL)

REMOTE CONTROL PANEL & SWITCH

COPPER

TERMINAL

GROUND TERM.

(WIDE SLOT)

W

G

CONNECT

TO CASE

PLUG FOR

REMOTE CONTROL

POTENTIOMETER

REMOTE CONTROL

POTENTIOMETER BOX

B

*

WITH MACHINE NOT RUNNING, REMOVE JUMPER 42 TO

600 AT THE TERMINAL STRIP. CONNECT THESE LEADS

STRIP.

TO THE CORRESPONDING NUMBERS AT THE TERMINAL

CONTROL PANEL COMPONENTS

SHOWN AS VEIWED FROM REAR.

LEAD COLOR CODE

B-BLACK

G-GREEN

N-BROWN

R-RED

U-BLUE

W-WHITE

Y-YELLOW

ELECTRICAL SYMBOLS PER E1537

1

3

4

5

6

7

8

2

PIN CONFIGURATION

ON ENGINE

CONNECTOR

ALTERNATOR

G

G

41

602

600

42

CV ADAPTER

W

Y

W

Y

608

609

TO WELDING

GENERATOR

SA-250 THERMOSTAT

ASSEMBLY

#2 HEAVY LEAD

+

-

NEGATIVE CV OUTPUT TERMINAL

CONNECT TO NEGATIVE

BRUSH HOLDER

B

R

W

610

N

N

509

503

U

U

VV OUTPUT

TERMINAL

POSITIVE CV &

VV OUTPUT

TERMINAL

POS

NEG

600

602

54

58

OIL PRESSURE

GAUGE

53

54A

SI

60E

GND

55

CB2

CB4

58C

60F

FUSE

15A.

4

6

1

3

61

BOTTOM VIEW

SHOWN

()

59A

58D

R1

58A

ENGINE

PROTECTION

RELAY

50

G-2

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The wiring diagram specific to your code is pasted inside one of the enclosure panels of your machine.