TO USE THE CLASSIC II FOR DC

CONSTANT CURRENT STICK OR TIG

WELDING:

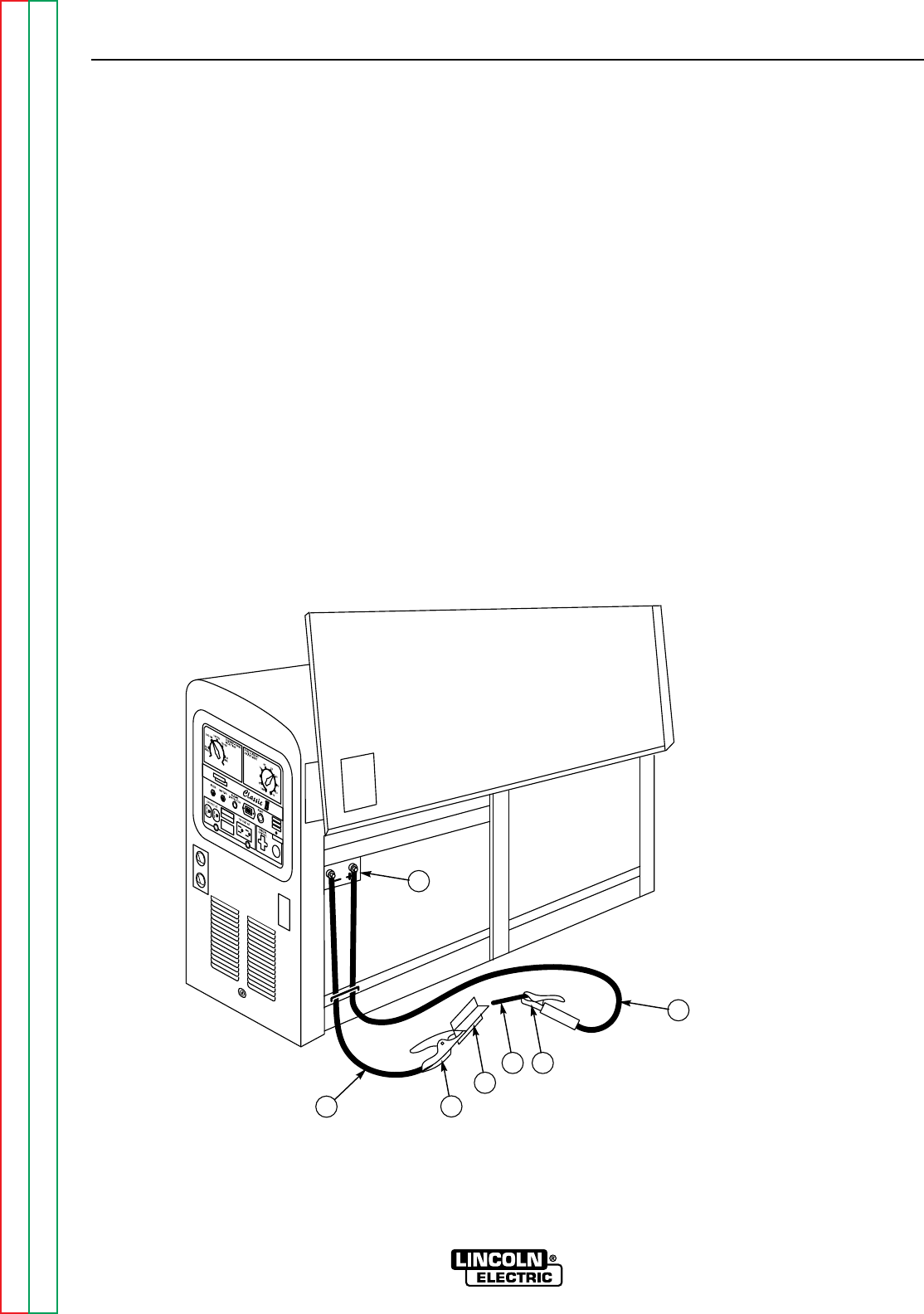

1. Remove the flange nuts from the weld output ter-

minals and place the work and electrode welding

cables over the terminals. For positive electrode,

connect the electrode cable to the + terminal and

the work cable to –. For negative electrode,

reverse the electrode and work cables at the

welder’s output terminals. See Figure B.4.

Replace and tighten the flange nuts securely. Be

sure the connections are tight.

2. Select the appropriate electrode.

3. Attach the work clamp securely to the work you are

welding.

4. Insert the electrode into the electrode holder.

5. Start the Diesel Engine. See

Engine Operation

in

this section of the manual.

6. Set the Idler Switch to "AUTO."

7. Set the CURRENT RANGE SELECTOR to a set-

ting equal to or slightly higher than the desired

welding current.

8. Set the FINE CURRENT ADJUSTMENT to the set-

ting that gives the best arc characteristics for the

range selected. See

Control of Welding Current

in this section of the manual.

9. Strike an arc and begin welding.

After you finish welding:

1. Stop the engine. See

Engine Operation

in this

section of the manual.

2. Allow the electrode and work to cool completely.

3. Remove the work clamp from the work.

4. Remove any remaining piece of electrode from the

electrode holder.

OPERATION

B-11 B-11

CLASSIC II

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE B.4 – WELDING CIRCUIT CONNECTIONS FOR STICK WELDING

80

1

2

34

5

6

7

1. OUTPUT TERMINALS

2. ELECTRODE CABLE

3. ELECTRODE HOLDER

4. ELECTRODE

5. WORK PIECE

6. WORK CLAMP

7. WORK CABLE