Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-12 F-12

CLASSIC II

TROUBLESHOOTING & REPAIR

TROUBLESHOOTING GUIDE Observe Safety Guidelines

detailed in the beginning of this manual.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con-

tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 216-

383-2531 or 1-800-833-9353.

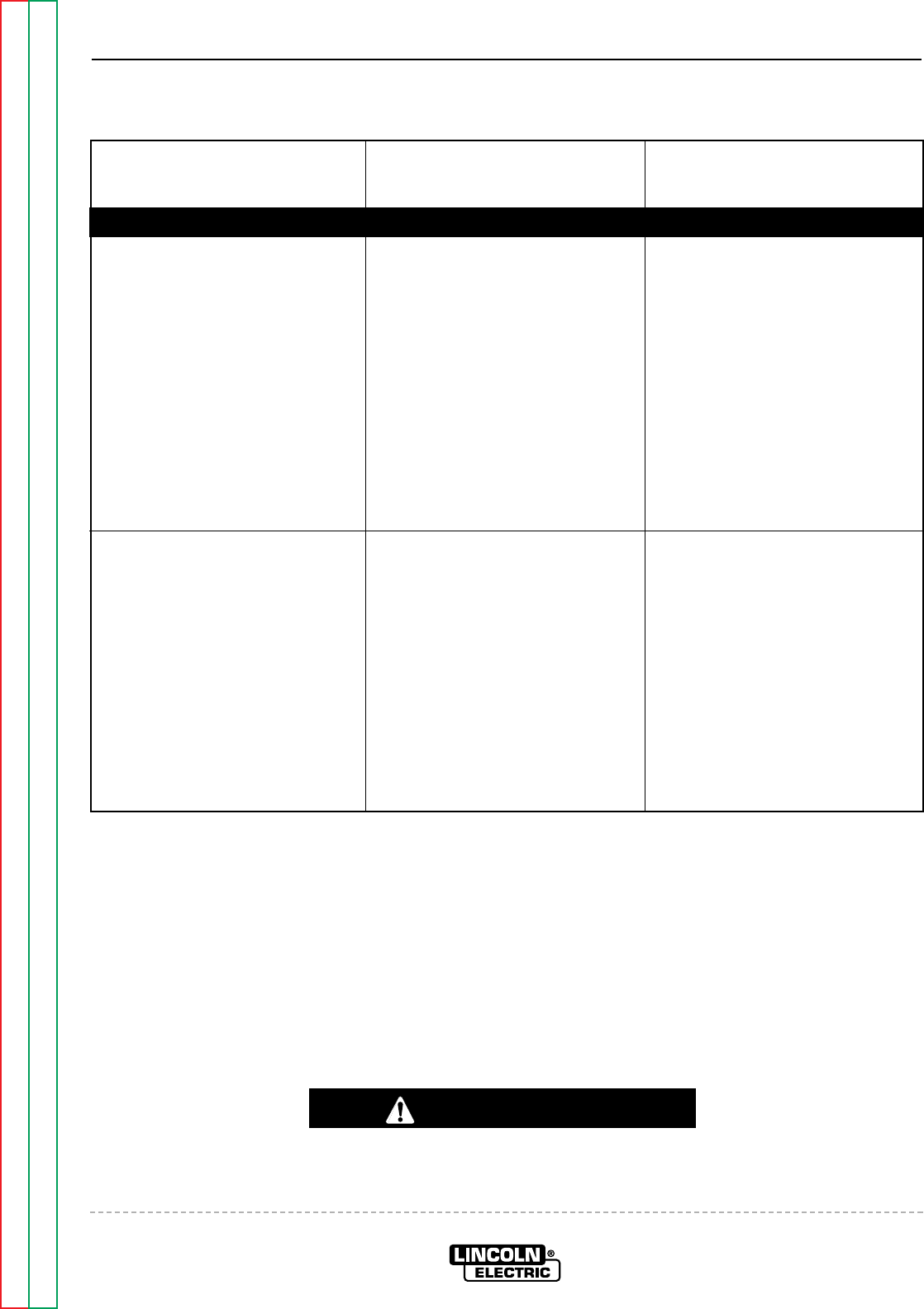

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

WELDING PROBLEMS

The welding arc is loud and spat-

ters excessively.

1. The current setting may be too

high for the electrode and

process.

2. The polarity may be wrong for

the electrode and process.

1. Check the engine speed. High

idle speed should be 1800

RPM.

2. Check the DC generator brush-

es for good commutation and

alignment. Contact the Lincoln

Electric Service Dept. at 1-216-

383-2531 or 1-800-833-9353

(WELD).

The welding arc frequently “pops

out.”

1. The Fine Current Control

Rheostat may be set too low for

the process and electrode.

2. Check the welding cables for

loose or faulty connections.

1. Check the engine speed. High

idle speed should be 1800

RPM.

2. The Current Range selector

switch may be faulty. Check for

proper operation.

3. Check the DC generator

brushes for good commutation

and alignment. Contact the

Lincoln Electric Service Dept. at

1-216-383-2531 or 1-800-833-

9353 (WELD).