7. Label and remove the four leads connected to the

two wire feeder circuit breakers. Pliers may be

necessary.

8. Label and remove the two leads connecting to the

CB2 circuit breaker. Pliers may be necessary.

9. Label and remove the seven leads from the

reconnect panel. Pliers may be necessary.

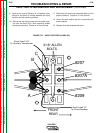

10. Using a crescent wrench, remove the large plastic

nut from around the input power line located at

bottom of the rear assembly. See Figure F.41.

11. Locate the steel nut located directly on the other

side of the rear assembly behind the plastic nut

that was previously removed. See Figure F.41.

12. Using a hammer and a flathead screwdriver, firm-

ly tap the metal nut from the bottom of one of its

ribs. This tapping will loosen the nut. Note: Be

sure to tap from the bottom so the nut loosens in

a counter clockwise fashion if viewed from the

front of the machine.

13. Using a 3/8” wrench label and remove leads #202,

#203, #206, #207A from the reconnect switches.

See Figure F.41.

TROUBLESHOOTING & REPAIR

CURRENT TRANSDUCER REMOVAL AND REPLACEMENT (continued)

F-91 F-91

V350-PRO

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

WARNING

REMOTE

POWER

OFF

ON

A

AMPS

A

V

VOLTS

WELD TERMINALS

SELECT

OUTPUT

LINCOLN

ELECTRIC

INVERTEC V350-PRO

Metal Nut

Plastic Nut

#203

#207A

#206

#202

FIGURE F.41 LEAD LOCATIONS