TROUBLESHOOTING AND REPAIR

CURRENT TRANSDUCER TEST (continued)

F-39 F-39

V350-PRO

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

9. Check the feedback voltage from the current

transducer using a resistive load bank and

with the V350-PRO in mode 200. Mode 200 is

a constant current test mode. This mode can

be accessed from the front panel of the V350

by pressing and holding the Mode Select but-

ton while turning the machine on. Then, rotate

the output knob while still holding the Mode

Select button in until the displays read “Mode

200”. Release the Mode Select Button and

the machine will be in mode 200. With the

V350-PRO in mode 200, apply the grid load

across the output of the V350-PRO, set

machine output to 300 amps and enable

WELD TERMINALS. Adjust the grid load to

obtain 300 amps on the external ammeter and

check feedback voltages per Table F.5.

A. Pin 1 (lead 801) to Pin 6 (lead 806) should

read 2.4 VDC (machine loaded to 300

amps).

10. If for any reason the machine cannot be

loaded to 300 amps, Table F.5. shows what

feedback voltage is produced at various cur-

rent loads.

11. If the correct supply voltages are applied to

the current transducer, and with the machine

loaded, the feedback voltage is missing or not

correct the current transducer may be faulty.

Before replacing the current transducer, check

the leads and plugs between the control board

(J8) and the current transducer (J90). See The

Wiring Diagram. For access to plug J90 and

the current transducer refer to: Current

Transducer Removal and Replacement

Procedure.

12. Remove input power to the V350-PRO.

13. Replace the control box top and any cable ties

previously removed.

14. Install the case wraparound cover using the

5/16” nut driver.

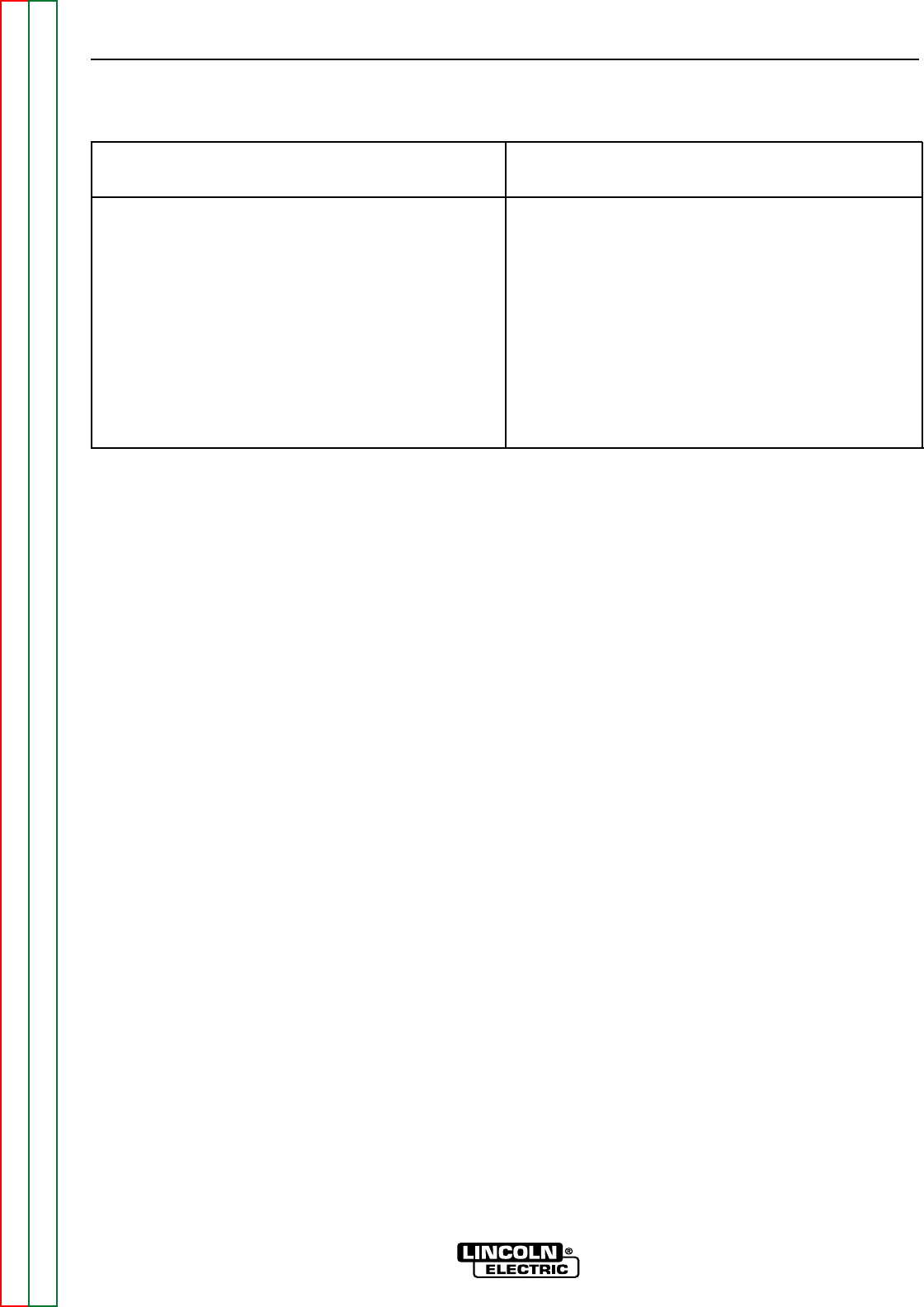

TABLE F.5

OUTPUT LOAD CURRENT

EXPECTED TRANSDUCER FEEDBACK

VOLTAGE

300

250

200

150

100

2.4

2.0

1.6

1.2

0.8