3-1.

VOLT-AMPERE

CURVES

(Chart

3-1)

3-3.

DESCRIPTION

(~3*

RATED

OUTPUT

The

volt-ampere

curves

show

the

voltage

and

amper

age

output

capabilities

of

the

unit.

Voltage

and

amper

age

adjustment

is

provided

by

the

FINE

TUNING

WIRE

SPEED

control.

Curves

of

other

setting

fall

between

the

curves

shown.

With

the

use

of

the

volt-ampere

curves,

it

is

possible

to

determine

the

weld

amperage

at

any

particular

load

volt-

age.

3-2.

DUTY

CYCLE

(Chart

3-2)

The

duty

cycle

is

the

percentage

of

a

ten

minute

period

that

a

welding

power

source

can

be

operated

at

a

given

output

without

overheating

and

damaging

the

unit.

This

welding

power

source

is

rated

at

60

percent

duty

cycle

when

operated

at

150

amperes.

The

unit

can

be

oper

ated

at

150

amperes

for

six

consecutive

minutes,

but

it

must

operate

at

no

load

for

the

remaining

four

minutes

to

allow

proper

cooling.

If

the

welding

amperes

decrease,

the

duty

cycle

increases.

Refer

to

the

Duty

Cycle

chart

(Chart

3-2)

to

determine

the

output

of

the

welding

power

source

at

various

duty

cycles.

a

CAUTION:

EXCEEDING

DUTY

CYCLE

RATINGS

will

damage

the

welding

power

source.

Do

not

exceed

indicated

duty

cycles.

This

unit

is

a

single-phase

constant

voltage

dc

arc

weld

ing

power

source

and

wire

feeder

system.

This

unit

is

de

signed

for

Gas

Metal

Arc

Welding

(GMAW)

with

short

circuit

or

spray

transfer.

It

is

designed

primarily

for

use

as

a

dc

Electrode

Positive/Reverse

Polarity

machine.

Rated

weld

output

is

150

amperes,

23

volts

dc,

at

60%

duty

cycle.

Models

with

the

optional

SPOT/PULSE

WELD

PANEL

provide

the

controls

for

regulating

spot

weld

time/pulse

on

time,

burnback

time,

and

pulse

off

time.

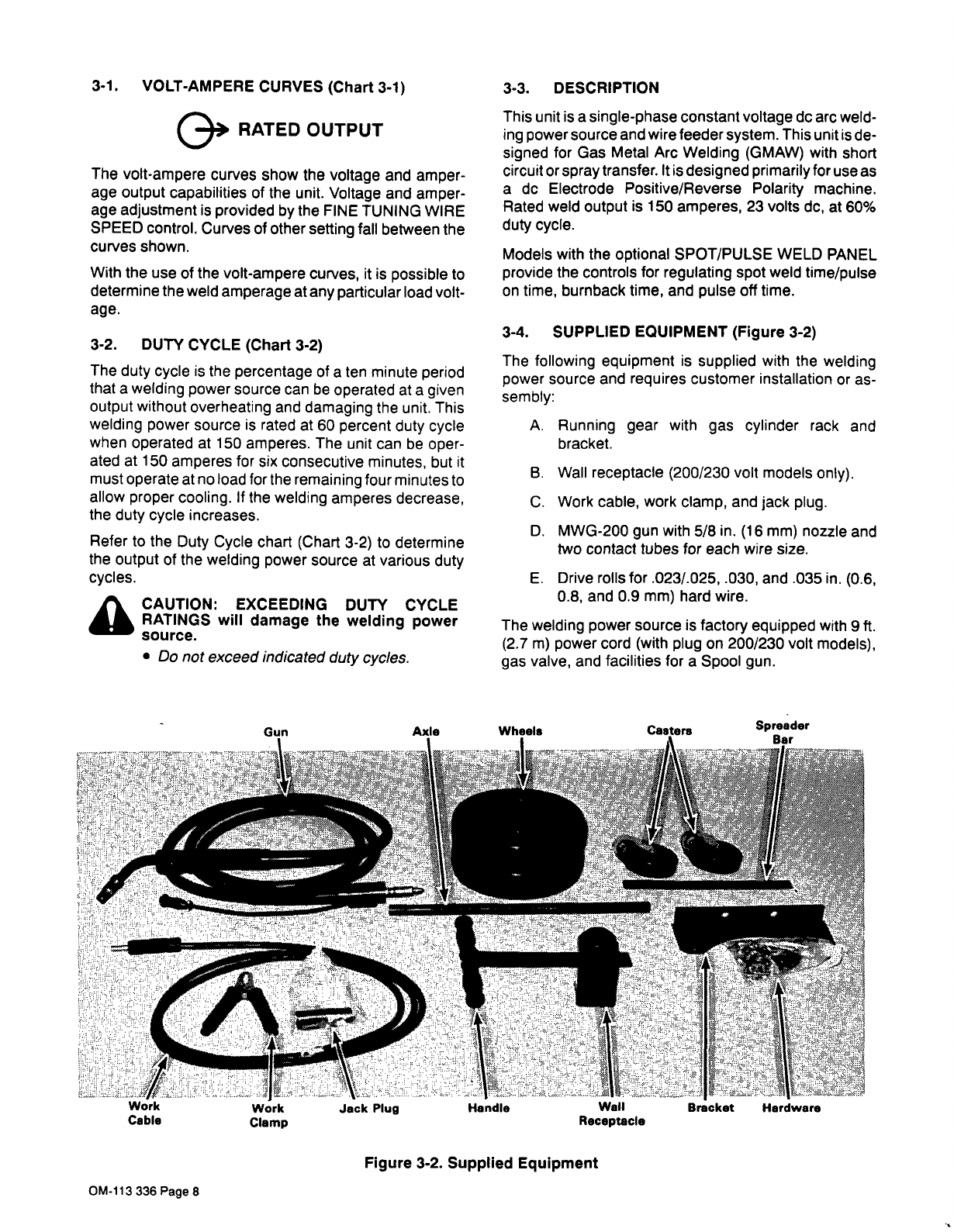

3-4.

SUPPLIED

EQUIPMENT

(Figure

3-2)

The

following

equipment

is

supplied

with

the

welding

power

source

and

requires

customer

installation

or

as

sembly:

A.

Running

gear

with

gas

cylinder

rack

and

bracket.

B.

Wall

receptacle

(200/230

volt

models

only).

C.

Work

cable,

work

clamp,

and

jack

plug.

D.

MWG-200

gun

with

5/8

in.

(16

mm)

nozzle

and

two

contact

tubes

for

each

wire

size.

E.

Drive

rolls

for

.023/.025,

.030,

and

.035

in.

(0.6,

0.8,

and

0.9

mm)

hard

wire.

The

welding

power

source

is

factory

equipped

with

9

ft.

(2.7

m)

power

cord

(with

plug

on

200/230

volt

models),

gas

valve,

and

facilities

for

a

Spool

gun.

Spreader

Bar

Figure

3-2.

Supplied

Equipment

Wall

Bracket

Receptacle

OM-113

336

Page

8