7-5.

INSPECTING

AND

REPLACING

MOTOR

BRUSHES

(Figure

7-1)

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shutdown

welding

powersource,

and

discon

nect

input

power

employing

lockout/tagging

procedures

before

inspecting,

maintaining,

or

servicing.

Lockout/tagging

procedures

Consist

of

removing

input

power

plug

from

receptacle,

padlocking

line

disconnect

switch

in

open

position,

remov

ing

fuses

from

fuse

box,

or

shutting

off

and

red-

tagging

circuit

breaker

or

other

disconnecting

device.

1.

Open

access

door.

2.

Remove

the

brush

caps

(two).

3.

Remove

brushes.

4.

Examine

brushes.

Replace

brushes

if

they

are

chipped

or

broken

or

if

less

than

1/4

in.

(6

mm)

of

brush

material

remains.

5.

Install

brushes,

and

secure

with

caps.

a

CAUTION:

DISASSEMBLY

OF

THE

MOTOR

FIELD

MAGNETS

can

result

in

personal

in

jury

and

equipment

damage.

Limit

drive

motor

repairs

to

brush

replace

ment.

The

field

magnets

are

very

strong.

If

disassem

bly

is

attempted,

injury

to

fingers

and

hands

may

result

from

the

rotor

being

drawn

back

into

the

motor.

The

field

magnets

are

matched

sets,

and

operation

may

be

affected

if

the

magnets

are

tampered

with.

Warranty

is

void

if

the

motor

is

tampered

with.

6.

Close

and

secure

access

door.

7-6.

OVERLOAD

PROTECTION

WARNING:

ELECTRIC

SHOCK

can

kill.

.

Do

not

touch

live

electrical

parts.

Shutdown

welding

powersource,

and

discon

nect

input

power

employing

lockout/tagging

procedures

before

inspecting,

maintaining,

or

servicing.

Lockout/tagging

procedures

consist

of

removing

input

power

plug

from

receptacle,

padlocking

line

disconnect

switch

in

open

position,

remov

ing

fuses

from

fuse

box,

or

shutting

off

and

red-

tagging

circuit

breaker

or

other

disconnecting

device.

A.

Circuit

Breaker

CB1

a

WARNING:

Read

and

follow

safety

informa

tion

at

beginning

of

entire

Section

7-6

before

proceeding.

The

drive

motor

is

protected

from

damage

due

to

over

load

by

circuit

breaker

CB1,

located

under

the

access

door.

Should

an

overload

on

CB1

occur,

the

contactorW

coil

would

open

thereby

stopping

all

output

from

the

welding

power

source.

If

CB1

opens,

manually

reset

the

circuit

breaker

as

fol

lows:

1.

Open

access

door.

2.

Check

for

jammed

wire

or

clogged

gun

liner,

and

correct

problem.

If

motor

overload

occurs

repeat

edly,

repair

or

replace

the

motor

or

liner.

3.

Check

for

binding

drive

gear

or

misaligned

drive

rolls,

and

correct

problem.

4.

Reset

circuit

breaker

CB1

(depress

button);

it

may

be

necessary

to

allow

a

cooling

period

before

the

breaker

can

be

reset.

5.

Close

and

secure

access

door.

6.

Resume

operation.

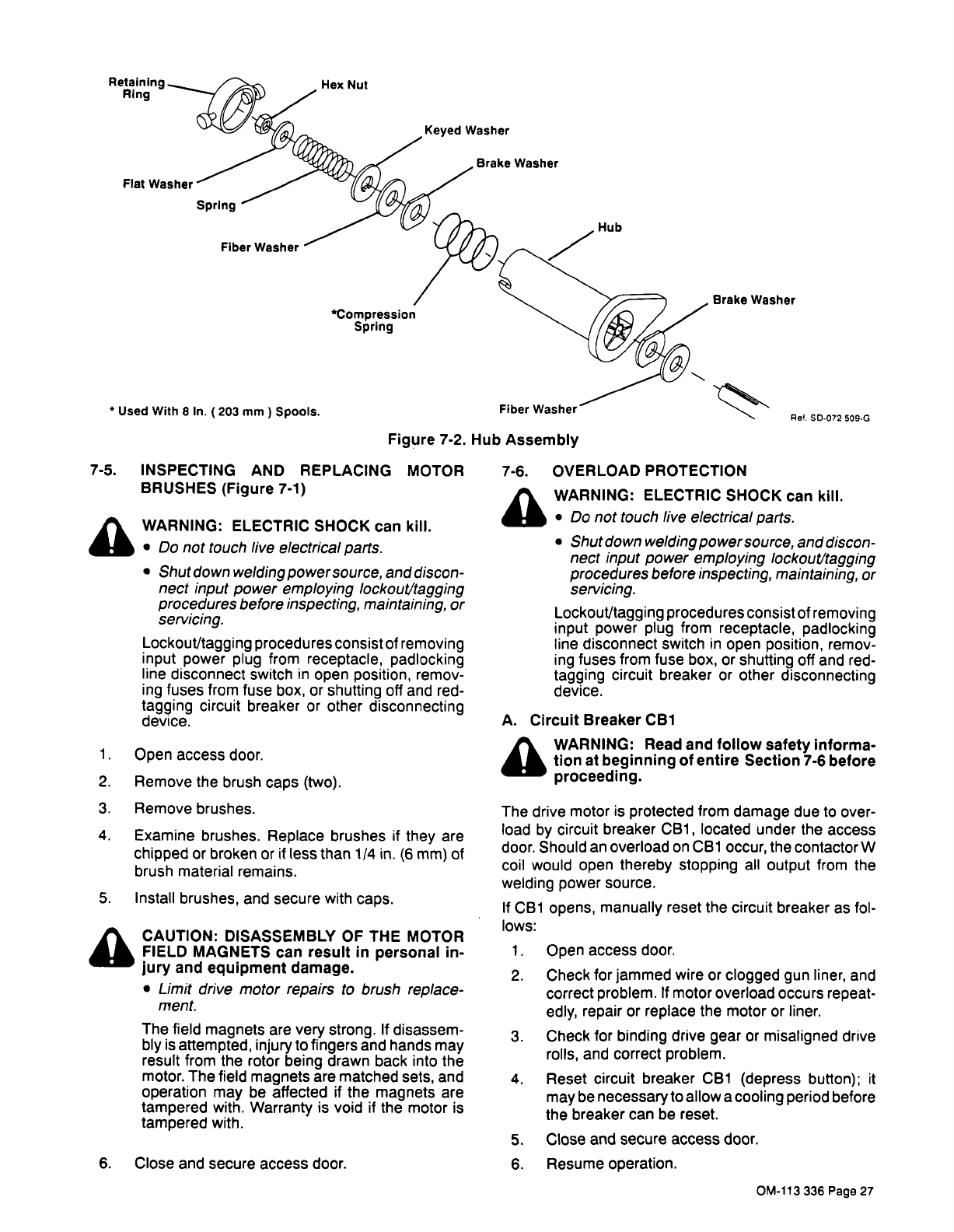

Hex

Nut

Keyed

Washer

Washer

Fiber

Washer

Retaining

Ring

Spring

*COmpreSsion

Spring

*

Used

With

8

In.

(203

mm)

Spools.

Hub

Brake

Washer

Fiber

Washer

Figure

7-2.

Hub

Assembly

Pef.

SD.072

509G

OM-113

336

Page

27