9-4.

PLUG

WELDS

Plug

welds

provide

a

means

of

joining

two

pieces

of

metal

where

the

thickness

of

the

top

sheet

is

beyond

the

normal

range

of

the

welding

power

source

or

where

sheet

metal

sections

are

too

thin

to

be

spot

welded

or

pulsed

welded

without

producing

distortion

or

burn

throughs.

The

plug

weld

is

made

by

drilling

or

punching

a

hole

in

the

top

sheet,

clamping

the

metal

sections

tightly

together,

and

filling

the

hole

with

a

weldment.

The

plug

weld

can

be

timed

using

the

spot

timer

or

untimed.

Plug

welds

should

be

spaced

1

to

1-1/2

inches

(25-38

mm)

apart.

Plug

welds

on

sample

materials

should

be

made

so

that

proper

parameters

can

be

set.

9-5.

SKIP

WELDING

Skip

welding

provides

a

means

of

making

a

series

of

short

welds,

usually

less

than

3/4

in.,

(18

mm)

in

length

each,

consistent

in

size

and

appearance.

Skip

welding

can

be

accomplished

with

this

unit

by

setting

a

spot

weld

time

and

jogging

the

gun

trigger

off

and

on

again

each

time

the

spot

timer

times

out.

Skip

welds

on

sample

material

should

be

made

so

that

proper

parameters

can

be

set.

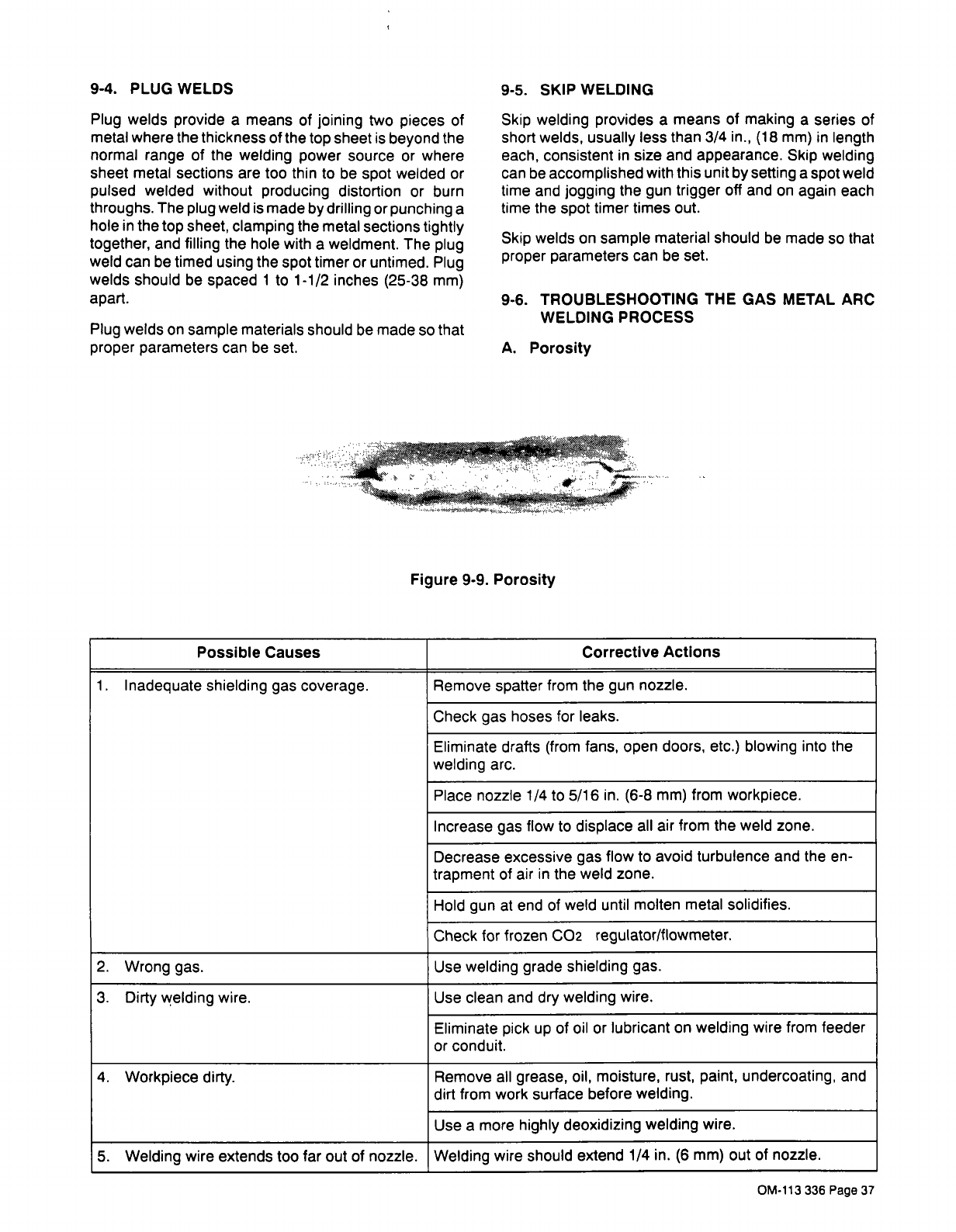

9-6.

TROUBLESHOOTING

THE

GAS

METAL

ARC

WELDING

PROCESS

A.

Porosity

Figure

9-9.

Porosity

Remove

spatter

from

the

gun

nozzle.

Check

gas

hoses

for

leaks.

Eliminate

drafts

(from

fans,

open

doors,

etc.)

blowing

into

the

welding

arc.

Place

nozzle

1/4

to

5/16

in.

(6-8

mm)

from

workpiece.

Increase

gas

flow

to

displace

all

air

from

the

weld

zone.

Decrease

excessive

gas

flow

to

avoid

turbulence

and

the

en

trapment

of

air

in

the

weld

zone.

Hold

gun

at

end

of

weld

until

molten

metal

solidifies.

Check

for

frozen

C02

regulator/flowmeter.

2.

Wrong

gas.

Use

welding

grade

shielding

gas.

3.

Dirty

welding

wire.

Use

clean

and

dry

welding

wire.

Eliminate

pick

up

of

oil

or

lubricant

on

welding

wire

from

feeder

or

conduit.

4.

Workpiece

dirty.

Remove

all

grease,

oil,

moisture,

rust,

paint,

undercoating,

and

dirt

from

work

surface

before

welding.

Use

a

more

highly

deoxidizing

welding

wire.

5.

Welding

wire

extends

too

far

out

of

nozzle.

Welding

wire

should

extend

1/4

in.

(6

mm)

out

of

nozzle.

Possible

Causes

1.

Inadequate

shielding

gas

coverage.

Corrective

Actions

OM-113

336

Page

37