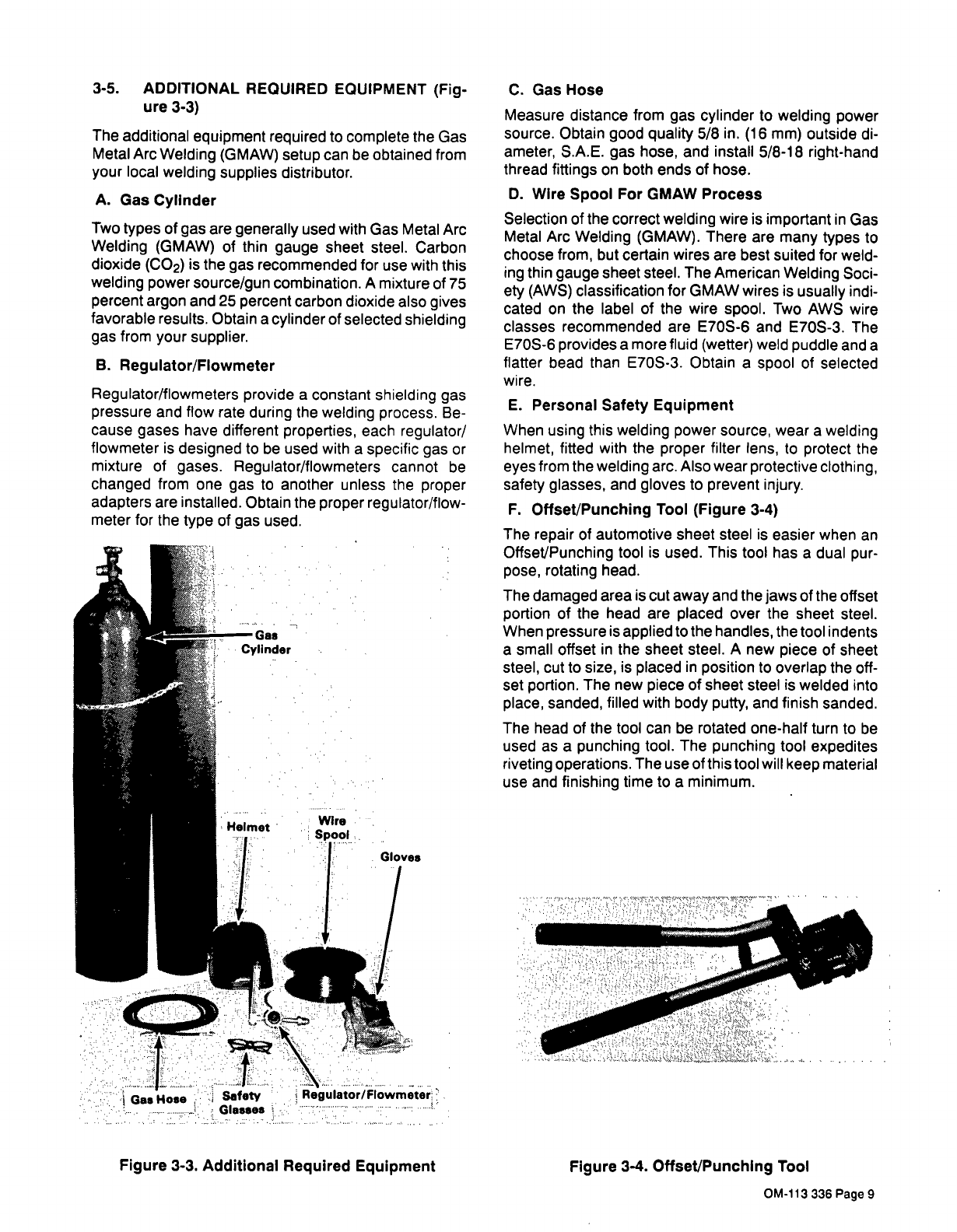

3-5.

ADDITIONAL

REQUIRED

EQUIPMENT

(Fig

ure

3-3)

The

additional

equipment

required

to

complete

the

Gas

Metal

Arc

Welding

(GMAW)

setup

can

be

obtained

from

your

local

welding

supplies

distributor.

A.

Gas

Cylinder

Two

types

of

gas

are

generally

used

with

Gas

Metal

Arc

Welding

(GMAW)

of

thin

gauge

sheet

steel.

Carbon

dioxide

(002)

is

the

gas

recommended

for

use

with

this

welding

power

source/gun

combination.

A

mixture

of

75

percent

argon

and

25

percent

carbon

dioxide

also

gives

favorable

results.

Obtain

a

cylinder

of

selected

shielding

gas

from

your

supplier.

B.

Regulator/Flowmeter

Regulator/flowmeters

provide

a

constant

shielding

gas

pressure

and

flow

rate

during

the

welding

process.

Be

cause

gases

have

different

properties,

each

regulator!

flowmeter

is

designed

to

be

used

with

a

specific

gas

or

mixture

of

gases.

Regulator/flowmeters

cannot

be

changed

from

one

gas

to

another

unless

the

proper

adapters

are

installed.

Obtain

the

proper

regulator/flow-

meter

for

the

type

of

gas

used.

Gas

Hose

Safety

Regulator/Flowmeter

Glasses

Figure

3-3.

Additional

Required

Equipment

C.

Gas

Hose

Measure

distance

from

gas

cylinder

to

welding

power

source.

Obtain

good

quality

5/8

in.

(16

mm)

outside

di

ameter,

S.A.E.

gas

hose,

and

install

5/8-18

right-hand

thread

fittings

on

both

ends

of

hose.

D.

Wire

Spool

For

GMAW

Process

Selection

of

the

correct

welding

wire

is

important

in

Gas

Metal

Arc

Welding

(GMAW).

There

are

many

types

to

choose

from,

but

certain

wires

are

best

suited

for

weld

ing

thin

gauge

sheet

steel.

The

American

Welding

Soci

ety

(AWS)

classification

for

GMAW

wires

is

usually

indi

cated

on

the

label

of

the

wire

spool.

Two

AWS

wire

classes

recommended

are

E7OS-6

and

E705-3.

The

E7OS-6

provides

a

more

fluid

(wetter)

weld

puddle

and

a

flatter

bead

than

E7OS-3.

Obtain

a

spool

of

selected

wire.

E.

Personal

Safety

Equipment

When

using

this

welding

power

source,

wear

a

welding

helmet,

fitted

with

the

proper

filter

lens,

to

protect

the

eyes

from

the

welding

arc.

Also

wear

protective

clothing,

safety

glasses,

and

gloves

to

prevent

injury.

F.

Offset/Punching

Tool

(Figure

3-4)

The

repair

of

automotive

sheet

steel

is

easier

when

an

OffsetlPunching

tool

is

used.

This

tool

has

a

dual

pur.

pose,

rotating

head.

The

damaged

area

is

cutaway

and

the

jaws

of

the

offset

portion

of

the

head

are

placed

over

the

sheet

steel.

When

pressure

is

applied

to

the

handles,

the

tool

indents

a

small

offset

in

the

sheet

steel.

A

new

piece

of

sheet

steel,

cut

to

size,

is

placed

in

position

to

overlap

the off

set

portion.

The

new

piece

of

sheet

steel

is

welded

into

place,

sanded,

filled

with

body

putty,

and

finish

sanded.

The

head

of

the

tool

can

be

rotated

one-half

turn

to

be

used

as

a

punching

tool.

The

punching

tool

expedites

riveting

operations.

The

use

of

this

tool

will

keep

material

use

and

finishing

time

to

a

minimum.

Figure

3-4.

Offset/Punching

Tool

Gas

Cylinder

Helmet

Wire

Spool

Gloves

Li.

/

1.

I

OM-113

336

Page

9