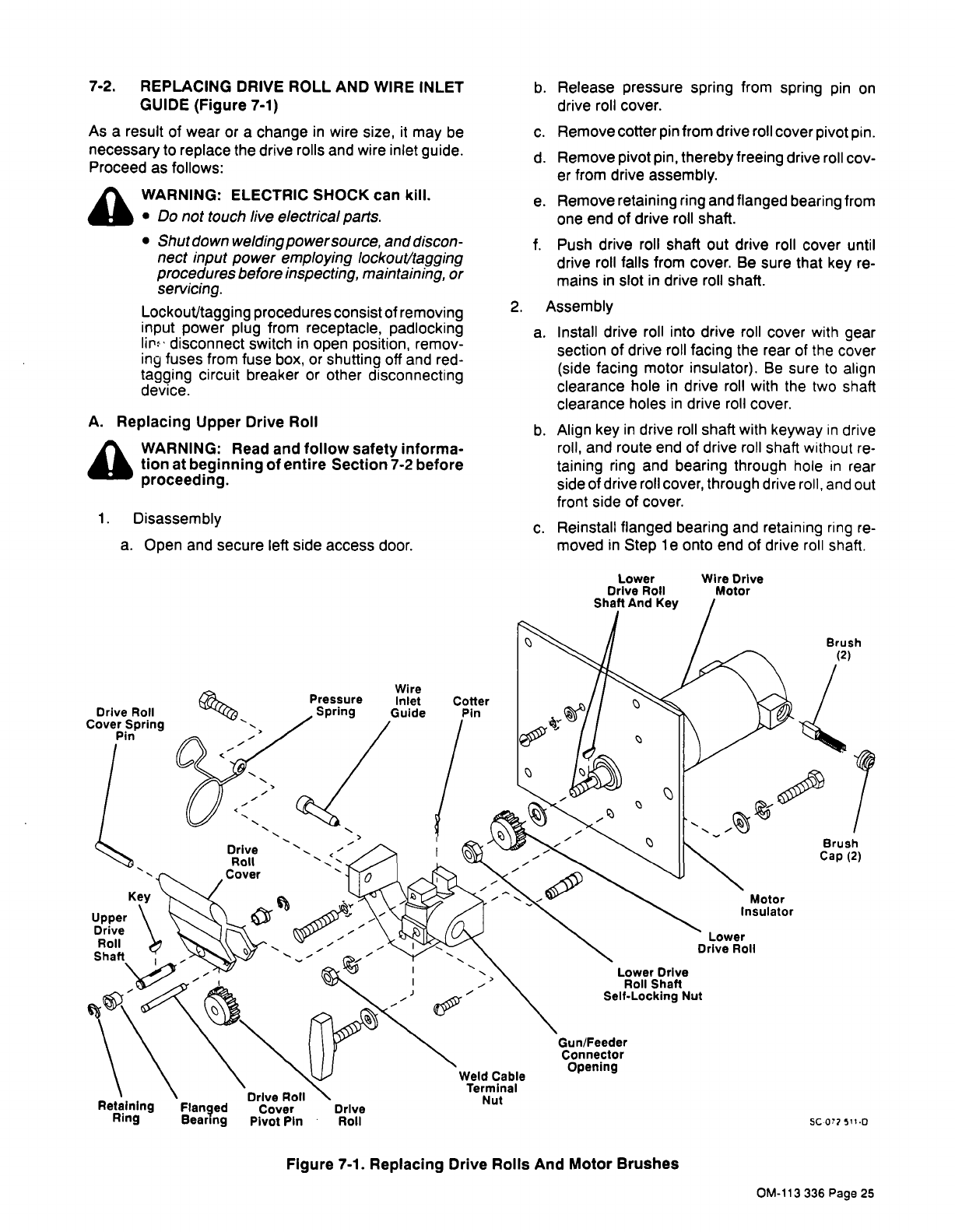

7-2.

REPLACING

DRIVE

ROLL

AND

WIRE

INLET

GUIDE

(Figure

7-1)

As

a

result

of

wear

or

a

change

in

wire

size,

it

may

be

necessary

to

replace

the

drive

rolls

and

wire

inlet

guide.

Proceed

as

follows:

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shut

down

welding

powersource,

and

discon

nect

input

power

employing

lockouVtagging

procedures

before

inspecting,

maintaining,

or

seivicing.

Lockout/tagging

procedures

consist

of

removing

input

power

plug

from

receptacle,

padlocking

lir~

disconnect

switch

in

open

position,

remov

ing

fuses

from

fuse

box,

or

shutting

off

and

red-

tagging

circuit

breaker

or

other

disconnecting

device.

A.

Replacing

Upper

Drive

Roll

a

WARNING:

Read

and

follow

safety

informa

tion

at

beginning

of

entire

Section

7-2

before

proceeding.

1.

Disassembly

a.

Open

and

secure

left

side

access

door.

b.

Release

pressure

spring

from

spring

pin

on

drive

roll

cover.

c.

Remove

cotter

pin

from

drive

roll

cover

pivot

pin.

d.

Remove

pivot

pin,

thereby

freeing

drive

roll

cov

er

from

drive

assembly.

e.

Remove

retaining

ring

and

flanged

bearing

from

one

end

of

drive

roll

shaft.

f.

Push

drive

roll

shaft

out

drive

roll

cover

until

drive

roll

falls

from

cover.

Be

sure

that

key

re

mains

in

slot

in

drive

roll

shaft.

Install

drive

roll

into

drive

roll

cover

with

gear

section

of

drive

roll

facing

the

rear

of

the

cover

(side

facing

motor

insulator).

Be

sure

to

align

clearance

hole

in

drive

roll

with

the

two

shaft

clearance

holes

in

drive

roll

cover.

b.

Align

key

in

drive

roll

shaft

with

keyway

in

drive

roll,

and

route

end

of

drive

roll

shaft

without

re

taining

ring

and

bearing

through

hole

in

rear

side

of

drive

roll

cover,

through

drive

roll,

and

out

front

side

of

cover.

c.

Reinstall

flanged

bearing

and

retaining

ring

re

moved

in

Step

le

onto

end

of

drive

roll

shaft.

2.

Assembly

a.

Lower

Wire

Drive

Drive

Roll

Motor

Shaft

And

Key

Wire

Inlet

Guide

Cotter

Pin

Drive

Roll

Cover

spring

Pin

Brush

(2)

Brush

Cap

(2)

Motor

Insulator

Lower

Drive

Roll

Lower

Drive

Roll

Shaft

Self-Locking

Nut

Gun/Feeder

Connector

Opening

Weld

Cable

Terminal

Nut

Drive

Roll

Retaining

Flanged

Cover

Drive

Ring

Bearing

Pivot

Pin

Roll

FIgure

7-1.

Replacing

Drive

Rolls

And

Motor

Brushes

OM-113

336

Page

25