SECTION

10

AUTO

BODY

REPAIR

APPLICATION

CAUTION:

WELDING

CURRENT

can

dam

age

vehicle

computers

and

other

electronic

components.

Disconnect

both

battery

cables

before

weld

ing

on

a

vehicle.

Place

work

clamp

as

close

to

the

weld

as

pos

sible

to

avoid

long

electrical

paths.

Be

sure

gun

to

power

source

as

well

as

cable

connections

to

work

clamp

are

clean

and

tight.

To

minimize

risk,

disconnect

the

computer(s)

from

the

vehicle.

10-1.

POINTERS

FOR

WELDING

AUTO

BODY

SHEET

METAL

Before

using

this

equipment

to

weld

on

a

finished

piece

of

work,

make

a

few

practice

welds

on

a

sample

piece

of

material

the

same

as

that

of

the

finished

workpiece.

Whenever

possible,

weld

in

the

flat

position

since

this

is

the

easiest

position

to

learn.

Be

sure

that

the

material

to

be

welded

is

clean

and

free

of

paint

and

rust.

The

work

cable

clamp

must

be

attached

to

the

parts

being

welded.

Clean

surface

to

ensure

proper

grounding

and

to

com

plete

the

current

path.

Use

a

.030

or

.023

in.

(0.8

or

0.6

mm)

E7OS-6

wire

and

argon/carbon

dioxide

shielding

gas.

Use

direct

current

straight

polarity

for

reduced

burn

through.

To

obtain

straight

polarity

(electrode

wire

to

negative-work

lead

to

positive),

place

the

Negative/

Positive

weld

output

selector

plug

in

the

NEGATIVE

WELD

OUTPUT

RECEPTACLE

and

connect

the

work

(ground)

lead

to

the

POSITIVE

WELD

OUTPUT

RE-

CE

PTACLE.

IMPORTANT:

For

maximum

penetration

on

thicker

ma

terials

such

as

18

gauge

(1.22

mm)

and

thicker,

recon

nect

for

direct

current

reverse

polarity

(work

lead

to

negative,

electrode

wire

to

positive).

10-2.

PROCEDURE

FOR

WELDING

MILD

STEELS

The

following

are

some

basic

guidelines

that

can

be

used

when

using

this

welding

power

source

to

weld

mild

or

high

strength

steels:

1.

Use

a

power

wire

brush

or

sander

to

remove

paint

to

bare

metal

in

the

area

to

be

repaired.

Two

to

three

inches

(51-76mm)

on

either

side

of

the

weld

area

should

be

cleaned

for

applying

body

filler

af

ter

welding

is

completed.

2.

Remove

damaged

metal

using

hand

cutters,

shears,

or

a

power

hand

grinder

equipped

with

a

cutting

wheel.

3. Fit

a

new

piece

of

sheet

steel

over

the

section

which

was

removed.

The

new

material

should

overlap

the

cut

away

section

by

one

inch

(25

mm).

4.

Clamp

the

new

metal

in

place,

and

prepare

to

spot

weld.

5.

Rotate

the

FINE

TUNING

WIRE

SPEED

control

to

50%,

the

weld

timer

at

30

to

40

percent,

the

burnback

at

40

to

50

percent

and

the

selector

switch

to

the

SPOT

position.

6.

Install

the

spot

nozzle

on

the

gun.

7.

With

the

shielding

gas

and

power

source

turned

on,

place

the

spot

nozzle

and

press

firmly

against

the

new

material

about

1/2

to

3/4

in.

(12-18

mm),

from

the

edge.

Fit

up

must

be

tight

to

assure

good,

repeatable

spot

welds.

8.

Begin

spot

welding

from

the

center

Out

on

each

side.

Distortion

may

occur

if

welding

begins

at

the

corners.

9.

Space

spot

welds

1

to

1/2

in.

(25-38

mm)

apart

around

repair.

Spot

welds

should

be

about

3/16

in.

(5

mm)

in

diameter.

IMPORTANT:

Do

not

make

continuous

welds

around

the

repair

as

this

will

promote

distortion

and

warpage.

10.

After

welding,

remove

the

clamp

and

grind

spot

flush

to

surface.

11.

Smooth

the

joints

with

body

filler

and

finish.

10-3.

PROCEDURES

FOR

WELDING

DOOR

PAN

ELS

IMPORTANT:

Every

experienced

autobody

repairman

will

ha

ye

his

own

methodofperforming

the

following

pro

cedures.

However,

this

in

formation

is

presented

to

show

how,

in

most

cases,

this

welding

powersource

can

make

the

job

easier

and

less

time

consuming.

If

the

door

is

severely

damaged,

but

the

damage

is

pri

marily

in

the

outer

panel,

or

skin,

the

door

can

be

easily

repaired

without

necessarily

installing

a

whole

new

door.

1.

Remove

exterior

molding

and

hardware.

It

is

not

necessary

to

remove

window

regulator,

remote

control

mechanisms,

lock

or

runs.

2.

Remove

door

assembly,

and

place

on

flat

surface

with

edges

of

door

extending

over

edges

of

sur

face

to

provide

room

to

work.

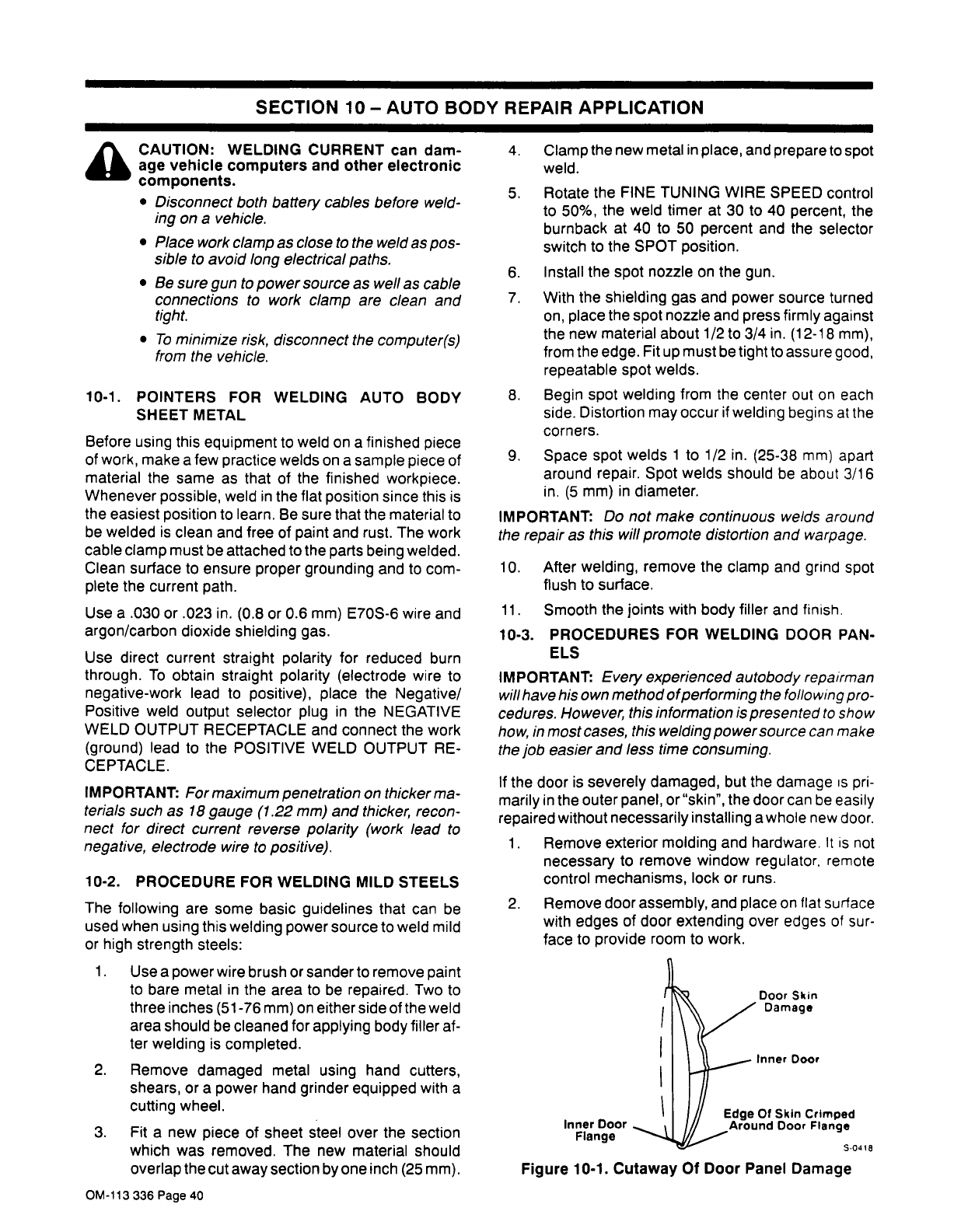

a

Door

Skin

Damage

Inner

Door

Inner

Door

Flange

Figure

10-1.

Cutaway

Of

Door

Panel

Damage

S

.~J4

18

OM-113

336

Page

40