B.

Circuit

Breaker

CB2

a

WARNING:

Read

and

follow

safety

informa

tion

at

beginning

of

entire

Section

7-6

before

proceeding.

Circuit

breaker

CB2

protects

the

24

volts

ac

winding

of

transformer

Ti

from

overload.

CB2

is

located

under

the

access

door.

Should

CB2

open,

the

contactor

W

coil

would

open

thereby

stopping

all

output

from

the

welding

power

source.

If

CB2

opens,

manually

reset

the

breaker.

7-7.

THERMAL

OVERLOAD

PROTECTION

Rectifier

SRi

is

protected

from

overheating

by

a

normally-closed

thermostat

TP3

wired

in

series

with

relay

CR1

and

contactor

W

coil

circuit.

Should

overheat

ing

occur,

TP3

would

open

causing

CR1

and

thereby

the

contactor

to

drop

out

(deenergize)

and

the

wire

drive

motor

to

stop,

thereby

stopping

all

weld

output.

If

this

condition

occurs,

it

will

be

necessary

to

allow

a

cooling

period

before

resuming

operation.

7-8.

PRINTED

CIRCUIT

BOARD

REPLACEMENT

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shutdown

welding

powersource,

and

discon

nect

input

power

employing

lockout/tagging

procedures

before

inspecting,

maintaining,

or

servicing.

Lockout/tagging

procedures

consist

of

removing

input

power

plug

from

receptacle,

padlocking

line

disconnect

switch

in

open

position,

remov

ing

fuses

from

fuse

box,

or

shutting

off

and

red-

tagging

circuit

breaker

or

other

disconnecting

device.

CAUTION:

ELECTROSTATIC

DISCHARGE

(ESD)

can

damage

circuit

boards.

Put

on

properly

grounded

wrist

strap

BE

FORE

handling

circuit

boards.

Transport

circuit

boards

in

proper

static-

shielding

carriers

or

packages.

Perform

work

only

at

a

static-safe

work

area.

INCORRECT

INSTALLATION

or

misaligned

plugs

can

damage

circuit

board.

Be

sure

that

plugs

are

properly

installed

and

aligned.

EXCESSIVE

PRESSURE

can

break

circuit

board.

Use

only

minimal

pressure

and

gentle

move

ment

when

disconnecting

or

connecting

board

plugs

and

removing

or

installing

board.

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shutdown

welding

powersource,

and

discon

nect

input

power

employing

lockout/tagging

procedures

before

inspecting,

maintaining,

or

servicing.

Lockout/tagging

procedures

consist

of

removing

input

power

plug

from

receptacle,

padlocking

line

disconnect

switch

in

open

position,

remov

ing

fuses

from

fuse

box,

or

shutting

off

and

red-

tagging

circuit

breaker

or

other

disconnecting

device.

MOVING

PARTS

can

cause

serious

injury.

Keep

away

from

moving

parts.

HOT

SURFACES

can

cause

severe

burns.

Allow

cooling

period

before

servicing.

Troubleshooting

to

be

performed

only

by

qualified

persons.

7-9.

TROUBLESHOOTING

a

a

It

is

assumed

that

the

unit

was

properly

installed

accord

ing

to

Section

4

of

this

manual,

the

operator

is

familiar

with

the

function

of

controls,

the

welding

power

source

was

working

property,

and

that

the

trouble

is

not

related

to

the

welding

process.

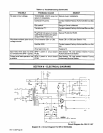

The

following

table

is

designed

to

diagnose

and

provide

remedies

for

some

of

the

troubles

that

may

develop

in

this

welding

power

source.

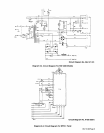

Use

this

table

in

conjunction

with

the

circuit

diagram

while

performing

troubleshoot

ing

procedures.

If

the

trouble

is

not

remedied

after

per

forming

these

procedures,

contact

the

nearest

Factory

Authorized

Service

Station.

In

all

cases

of

equipment

malfunction,

strictly

follow

the

manufacturers

proce

dures

and

instructions.

OM-113

336

Page

28