d.

Reinstall

drive

roll

cover

and

pivot

pin

into

drive

roll

assembly.

e.

Reinstall

cotter

pin

onto

pivot

pin.

f.

If

installing

or

changing

lower

drive

roll,

proceed

to

Section

7-2B;

otherwise,

reengage

pressure

spring

over

spring

pin

on

drive

roll

cover,

and

close

and

secure

access

door.

B.

Replacing

Lower

Drive

Roll

a

WARNING:

Read

and

follow

safety

informa

tion

at

beginning

of

entire

Section

7-2

before

proceeding.

1.

Disassembly

a.

If

applicable,

release

pressure

spring

from

spring

pin

on

drive

roll

cover.

b.

If

applicable,

pivot

upper

drive

roll

up,

awayfrom

lower

drive

roll.

c.

Remove

self-locking

nut

from

end

of

lower

drive

roll

shaft,

and

remove

drive

roll.

Be

sure

that

key

remains

in

slot

in

drive

roll

shaft.

2.

Assembly

a.

Install

drive

roll

onto

lower

drive

roll

shaft

align

ing

keyway

in

drive

roll

clearance

hole

with

key

in

drive

roll

shaft.

(Drive

roll

must

be

installed

with

gear

section

facing

the

motor

insulator.)

b.

Reinstall

self-locking

nut

onto

drive

roll

shaft.

c.

Adjust

horizontal

position

of

lower

drive

roll

in

or

out

as

necessary.

To

move

the

drive

roll

in

to

wards

the

motor

insulator,

rotate

the

self-lock

ing

nut

clockwise.

To

move

the

drive

roll

out

away

from

the

center

panel

of

the

unit,

rotate

the

nut

counterclockwise.

IMPORTANT:

Be

sure

that

upper

and

lower

drive

roll

gears

are

properly

meshed

and

the

drive

roll

grooves

are

aligned

when

adjusting

horizontal

position

of

lower

drive

roll.

d.

Reengage

pressure

spring

over

spring

pin

on

drive

roll

cover.

e.

If

replacing

wire

inlet

guide,

proceed

to

Section

7-20;

otherwise,

close

and

secure

side

access

door.

C.

Replacing

Wire

Inlet

Guide

1.

Loosen

wire

guide

securing

screw.

2.

Remove

wire

guide

from

drive

housing.

3.

Install

new

wire

guide

through

mounting

hole

in

left

side

of

drive

housing

(see

Figure

7-1).

IMPORTANT:

Wire

guide

should

be

installed

as

close

to

the

drive

rolls

as

possible

without

touching

them.

4.

Tighten

wire

guide

securing

setscrew.

5.

Close

and

secure

side

access

door.

7-3.

DRIVE

HOUSING

REALIGNMENT

(Figure

4-7)

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shutdown

welding

powersource,

and

discon

nect

input

power

employing

lockout/tagging

procedures

before

inspecting,

maintaining,

or

servicing.

Lockout/tagging

procedures

consist

of

removing

input

power

plug

from

receptacle,

padlocking

line

disconnect

switch

in

open

position,

remov

ing

fuses

from

fuse

box,

or

shutting

off

and

red-

tagging

circuit

breaker

or

other

disconnecting

device.

The

wire

drive

housing

is

made

with

mounting

holes

of

sufficient

clearance

to

provide

adjustment

of

the

wire

guides

up

or

down

in

relation

to

the

drive

rolls.

This

ad

justment

has

been

factory

set,

but

if

readjustment

be

comes

necessary

proceed

as

follows:

1.

Open

access

door.

2.

Loosen

mounting

bolts

and

the

weld

terminal

nut,

securing

wire

drive

housing

to

the

air

baffle.

3.

Slide drive

housing

upward

or

downward

until

the

wire

can

be

fed

straight

through

the

guides

while

seated

in

the

drive

roll.

4.

Tighten

mounting

bolts

and

weld

terminal

nut.

5.

Close

and

secure

access

door.

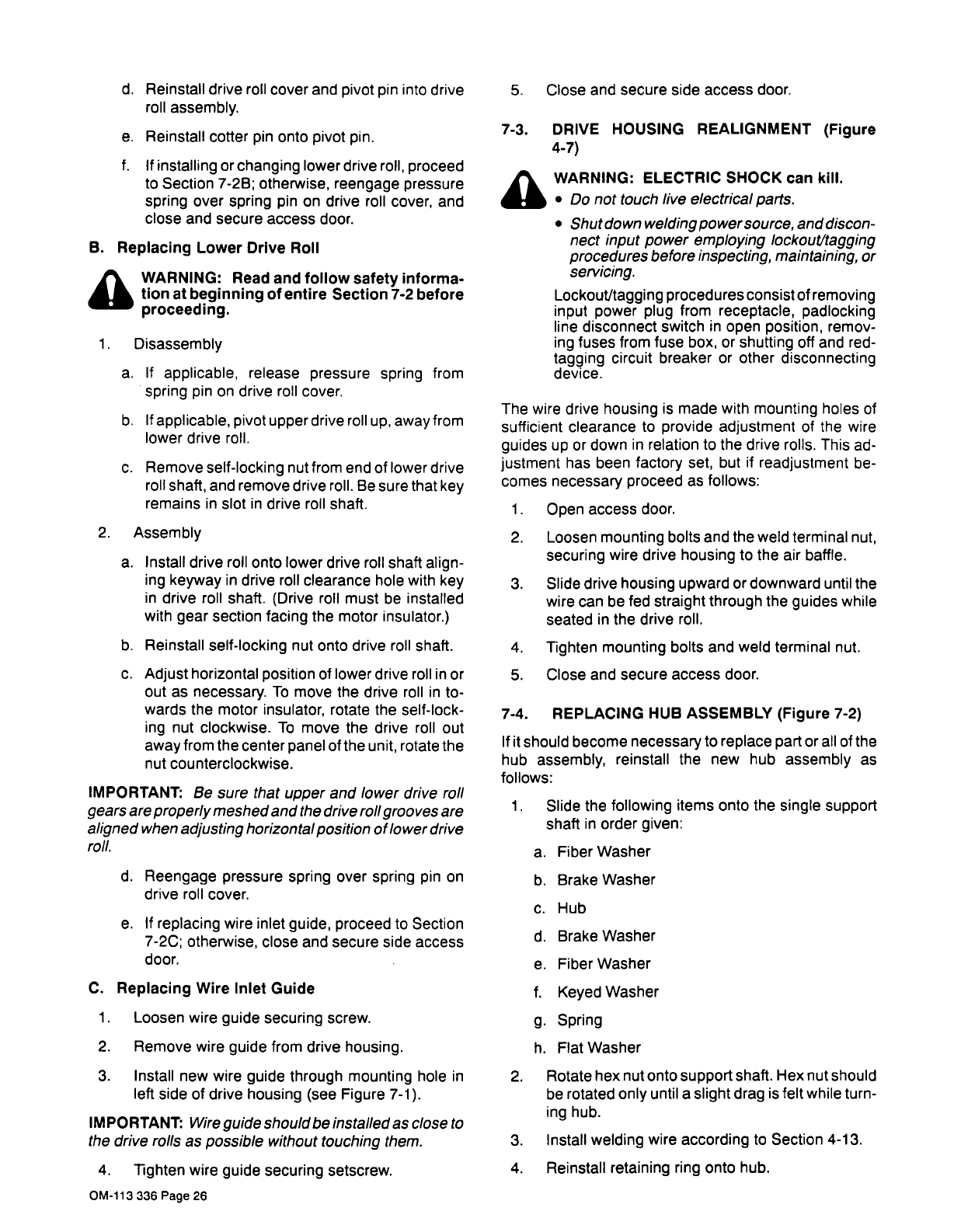

7-4.

REPLACING

HUB

ASSEMBLY

(Figure

7-2)

If

it

should

become

necessary

to

replace

part

or

all

of

the

hub

assembly,

reinstall

the

new

hub

assembly

as

follows:

1.

Slide

the

following

items

onto

the

single

support

shaft

in

order

given:

a.

Fiber

Washer

b.

Brake

Washer

c.

Hub

d.

Brake

Washer

e.

Fiber

Washer

f.

Keyed

Washer

g.

Spring

h.

Flat

Washer

2.

Rotate

hex

nut

onto

support

shaft.

Hex

nut

should

be

rotated

only

until

a

slight

drag

is

felt

while

turn

ing

hub.

3.

Install

welding

wire

according

to

Section

4-13.

4.

Reinstall

retaining

ring

onto

hub.

OM-113

336

Page

26