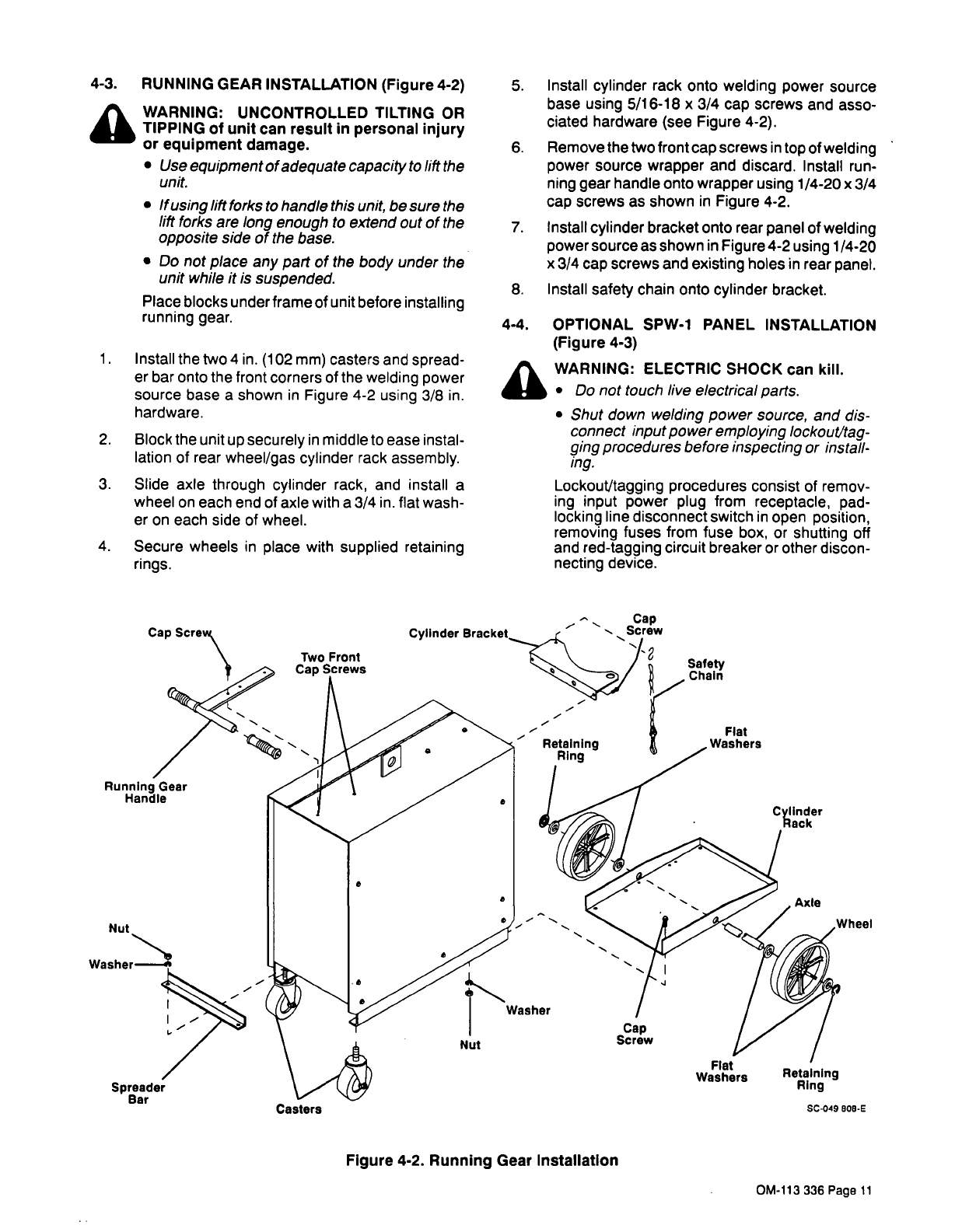

4-3.

RUNNING

GEAR

INSTALLATION

(Figure

4-2)

a

WARNING:

UNCONTROLLED

TILTING

OR

TIPPING

of

unit

can

result

in

personal

injury

or

equipment

damage.

Use

equipment

of

adequate

capacity

to

lift

the

unit.

If

using

lift

forks

to

handle

this

unit,

be

sure

the

lift

forks

are

long

enough

to

extend

out

of

the

opposite

side

of

the

base.

Do

not

place

any

part

of

the

body

under

the

unit

while

it

is

suspended.

Place

blocks

under

frame

of

unit

before

installing

running

gear.

1.

Install

the

two

4

in.

(102

mm)

casters

and

spread

er

bar

onto

the

front

corners

of

the

welding

power

source

base

a

shown

in

Figure

4-2

using

3/8

in.

hardware.

2.

Blockthe

unit

up

securely

in

middleto

ease

instal

lation

of

rear

wheel/gas

cylinder

rack

assembly.

3.

Slide

axle

through

cylinder

rack,

and

install

a

wheel

on

each

end

of

axle

with

a

3/4

in.

flat

wash

er

on

each

side

of

wheel.

4.

Secure

wheels

in

place

with

supplied

retaining

rings.

5.

Install

cylinder

rack

onto

welding

power

source

base

using

5/16-18

x

3/4

cap

screws

and

asso

ciated

hardware

(see

Figure

4-2).

6.

Remove

the

two

front

cap

screws

in

top

of

welding

power

source

wrapper

and

discard.

Install

run

ning

gear

handle

onto

wrapper

using

1/4-20

x

3/4

cap

screws

as

shown

in

Figure

4-2.

7.

Install

cylinder

bracket

onto

rear

panel

of

welding

power

source

as

shown

in

Figure

4-2

using

1/4-20

x

3/4

cap

screws

and

existing

holes

in

rear

panel.

8.

Install

safety

chain

onto

cylinder

bracket.

4-4.

OPTIONAL

SPW-1

PANEL

INSTALLATION

(Figure

4-3)

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shut

down

welding

power

source,

and

dis

connect

input

power

employing

lockout/tag

ging

procedures

before

inspecting

or

install.

ing.

Lockout/tagging

procedures

consist

of

remov

ing

input

power

plug

from

receptacle,

pad

locking

line

disconnect

switch

in

open

position,

removing

fuses

from

fuse

box,

or

shutting

off

and

red-tagging

circuit

breaker

or

other

discon

necting

device.

.wheel

SC-049

808-E

Figure

4-2.

Running

Gear

Installation

Cylinder

Safety

chain

Flat

Washers

Nut

Cylinder

Rack

Axle

Spreader

Bar

Washer

Casters

Nut

Cap

Screw

Flat

Washers

OM-113

336

Page

11