9-3.

GAS

METAL

ARC

WELDING

(GMAW)-SPOT

Instead

of

having

a

continuous

or

pulsed

weld

to

join

two

pieces

of

sheet

steel

together,

welding

in

spot

of

1

to

1-1/2

inches

(25-38

mm)

apart

can

be

done.

The

MIG

spot

welding

process

fuses

two

pieces

of

sheet

steel

to

gether

by

penetrating

entirely

through

one

of

the

pieces

into

the

other.

The

spot

process

is

designed

to

be

used

in

any

position.

Little

joint

preparation

is

required

other

than

cleaning

the

surfaces

and

ensuring

that

the

two

pieces

overlap.

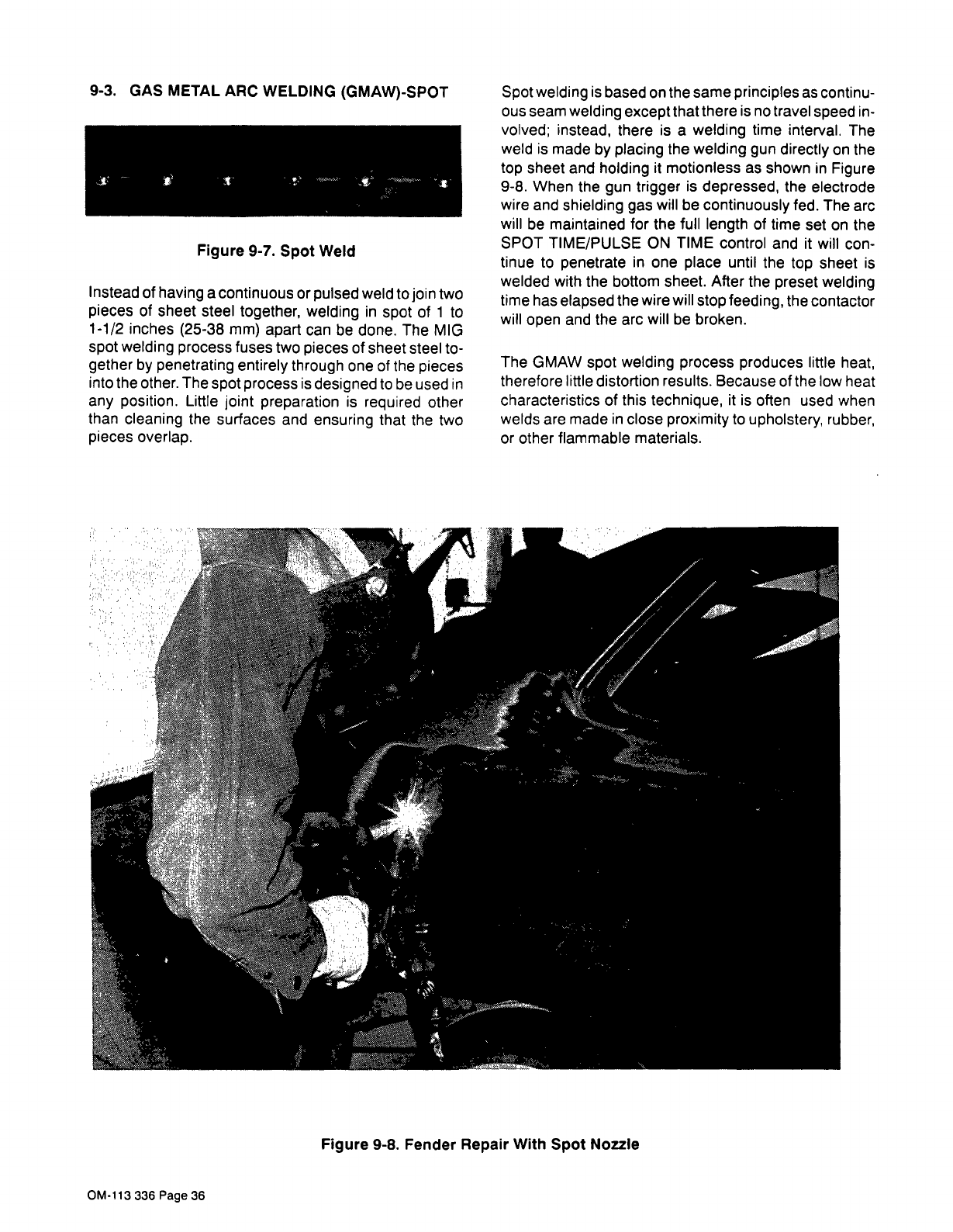

Spot

welding

is

based

on

the

same

principles

as

continu

ous

seam

welding

except

that

there

is

no

travel

speed

in

volved;

instead,

there

is

a

welding

time

interval.

The

weld

is

made

by

placing

the

welding

gun

directly

on

the

top

sheet

and

holding

it

motionless

as

shown

in

Figure

9-8.

When

the

gun

trigger

is

depressed,

the

electrode

wire

and

shielding

gas

will

be

continuously

fed.

The

arc

will

be

maintained

for

the

full

length

of

time

set

on

the

SPOT

TIME/PULSE

ON

TIME

control

and

it

will

con

tinue

to

penetrate

in

one

place

until

the

top

sheet

is

welded

with

the

bottom

sheet.

After

the

preset

welding

time

has

elapsed

the

wire

will

stop

feeding,

the

contactor

will

open

and

the

arc

will

be

broken.

The

GMAW

spot

welding

process

produces

little

heat,

therefore

little

distortion

results.

Because

of

the

low

heat

characteristics

of

this

technique,

it

is

often

used

when

welds

are

made

in

close

proximity

to

upholstery,

rubber,

or

other

flammable

materials.

Figure

9-8.

Fender

Repair

With

Spot

Nozzle

Figure

9-7.

Spot

Weld

OM-113

336

Page

36