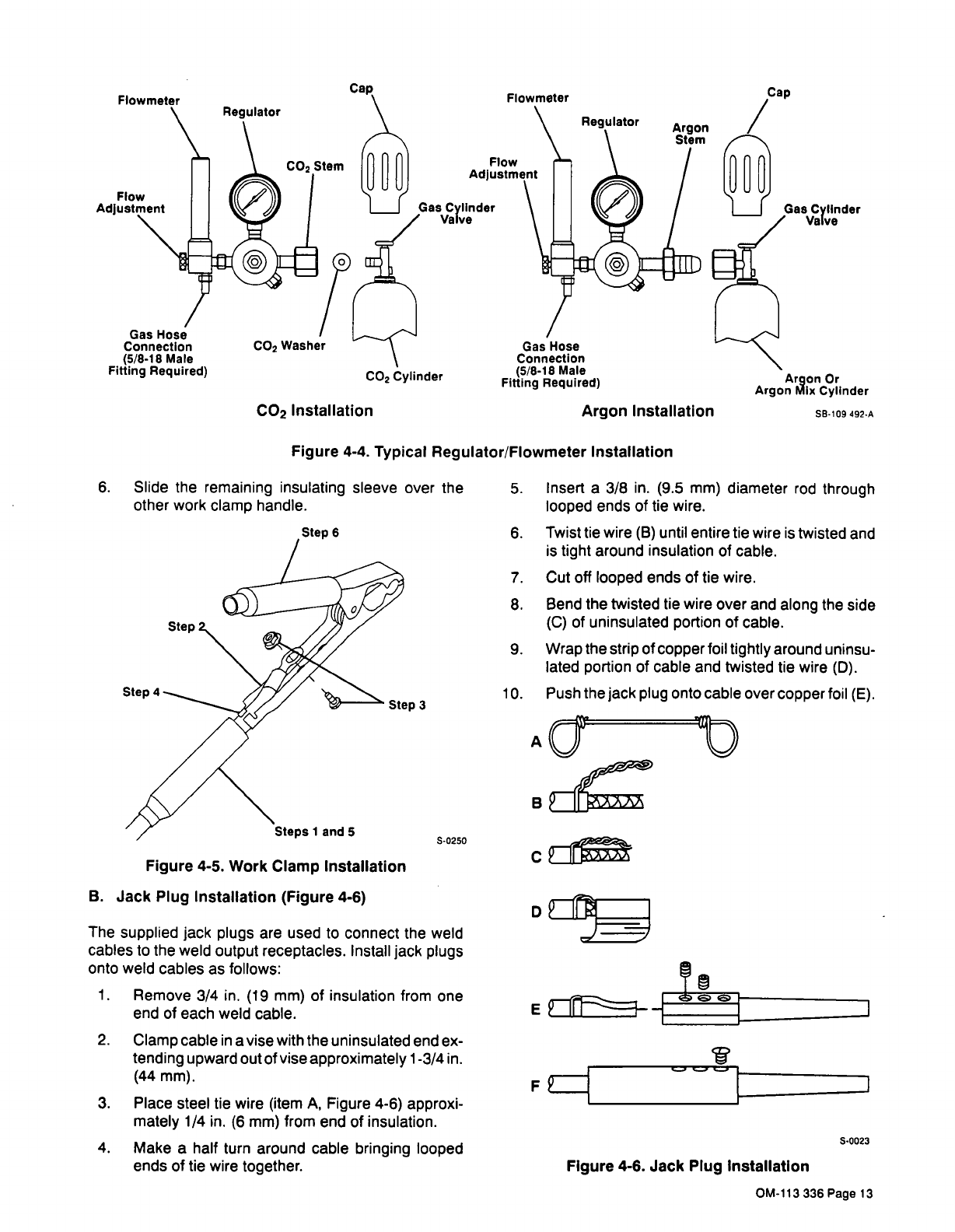

Regulator

CO2

Installation

SB-109

492-A

6.

Slide

the

remaining

insulating

sleeve

over

the

other

work

clamp

handle.

Step

3

Figure

4-5.

Work

Clamp

Installation

B.

Jack

Plug

Installation

(Figure

4-6)

0250

The

supplied

jack

plugs

are

used

to

connect

the

weld

cables

to

the

weld

output

receptacles.

Install

jack

plugs

onto

weld

cables

as

follows:

1.

Remove

3/4

in.

(19

mm)

of

insulation

from

one

end

of

each

weld

cable.

2.

Clamp

cable

in

a

vise

with

the

uninsulated

end

ex

tending

upward

out

of

vise

approximately

1-3/4

in.

(44

mm).

3.

Place

steel

tie

wire

(item

A,

Figure

4-6)

approxi

mately

1/4

in.

(6

mm)

from

end

of

insulation.

4.

Make

a

half

turn

around

cable

bringing

looped

ends

of

tie

wire

together.

5.

Insert

a

3/8

in.

(9.5

mm)

diameter

rod

through

looped

ends

of

tie

wire.

6.

Twist

tie

wire

(B)

until

entire

tie

wire

is

twisted

and

is

tight

around

insulation

of

cable.

7.

Cut

off

looped

ends

of

tie

wire.

8.

Bend

the

twisted

tie

wire

over

and

along

the

side

(C)

of

uninsulated

portion

of

cable.

9.

Wrap

the

strip

of

copper

foil

tightly

around

uninsu

lated

portion

of

cable

and

twisted

tie

wire

(D).

10.

Push

the

jack plug

onto

cable

over

copper

foil

(E).

AU

B~

~

U

FP

S~0023

Figure

4-6.

Jack

Plug

Installation

Gas

Hose

Connection

CO2

Washer

(5/8.18

Male

Fitting

Required)

CO2

Cylinder

Gas

Hose

Connection

(5/8-18

Male

Fitting

Required)

Argon

Installation

Argon

Or

Argon

Mix

Cylinder

Figure

4-4.

Typical

Regulator/Flowmeter

Installation

Step

6

Step

Step

4

Steps

1

and

5

OM-113

336

Page

13