3.

If

door

has

an

outer

panel

reinforcement,

break

the

weld.

4.

Grind

off

the

hem

flange

and

remove

the

old

panel.

5.

Repair

any

damage

to

the

inner

panel.

6.

Position

the

new

outer

panel

over

door

and

bend

the

end

flange

over

the

inner

flange.

7.

Spot

weld

outer

panel

reinforcement

to

new

door

panel.

Spot

weld

new

hem

flange

to

inner

panel.

Metal

finish

exterior

surface,

paint

and

assembly

interior

trim

and

hardware.

10-4.

HOW

TO

PREVENT

GLASS

BREAKAGE

AND

SPATTER

ON

WINDOWS

Spatter

and

excessive

heat

can

become

problems

when

welding

near

windows.

Protect

the

windows

by

keeping

them

covered

and

as

far

away

from

the

heat

zone

as

possible.

When

welding

must

be

performed

near

win

dows,

the

windows

should

be

covered

and

protected

from

excessive

heat

by

using

wet

rags.

A

putty

like

sub

stance

which

reduces

heat

transfer

is

available

through

your

welding

supplier,

If

burn

through

and

spatter

be

come

problems,

ensure

that

the

correct

voltage

tap

is

being

used

for

the

size

material

being

welded.

Use

an

ar

gon

and

002

gas

mixture

and

check

travel

speed.

10-5.

PROCEDURES

FOR

WELDING

FENDERS

AND

QUARTER

PANELS

When

a

complete

panel

must

be

replaced

it

will

be

nec

essary

to

remove

the

bolts

securing

the

panel

to

the

rest

of

the

structure,

or

to

cut

through

the

spot

welds

if

the

panel

is

welded

in

place.

In

most

cases

a

front

fender

will

be

bolted

in

place,

while

the

other

panels

will

be

either

spot

welded

or

continuous

seam

welded.

The

alignment

of

front

fenders

is

usually

simple

because

the

bolt

holes

are

often

elongated

so

that

the

position

of

the

new

front

fender

can

be

shifted

and

correctly

aligned.

Generally

all

other

panels

are

welded

into

place.

If

the

whole

panel

is

to

be

replaced,

the

old

panel

must

be

removed

by

cutting

along

the

weld

if

welded

by

continu

ous

seam,

or

by

drilling

out

the

spot

welds

if

it

is

spot

welded

in

place.

Car

and

body

manufacturers

have

the

panels

welded

in

different

places,

so

it

will

be

necessary

to

inspect

the

body

to

determine

where

the

welds

are

lo

cated

in

each

case.

After

the

old

panel

is

removed,

the

inner

panels

must

be

carefully

checked,

straightened

or

replaced.

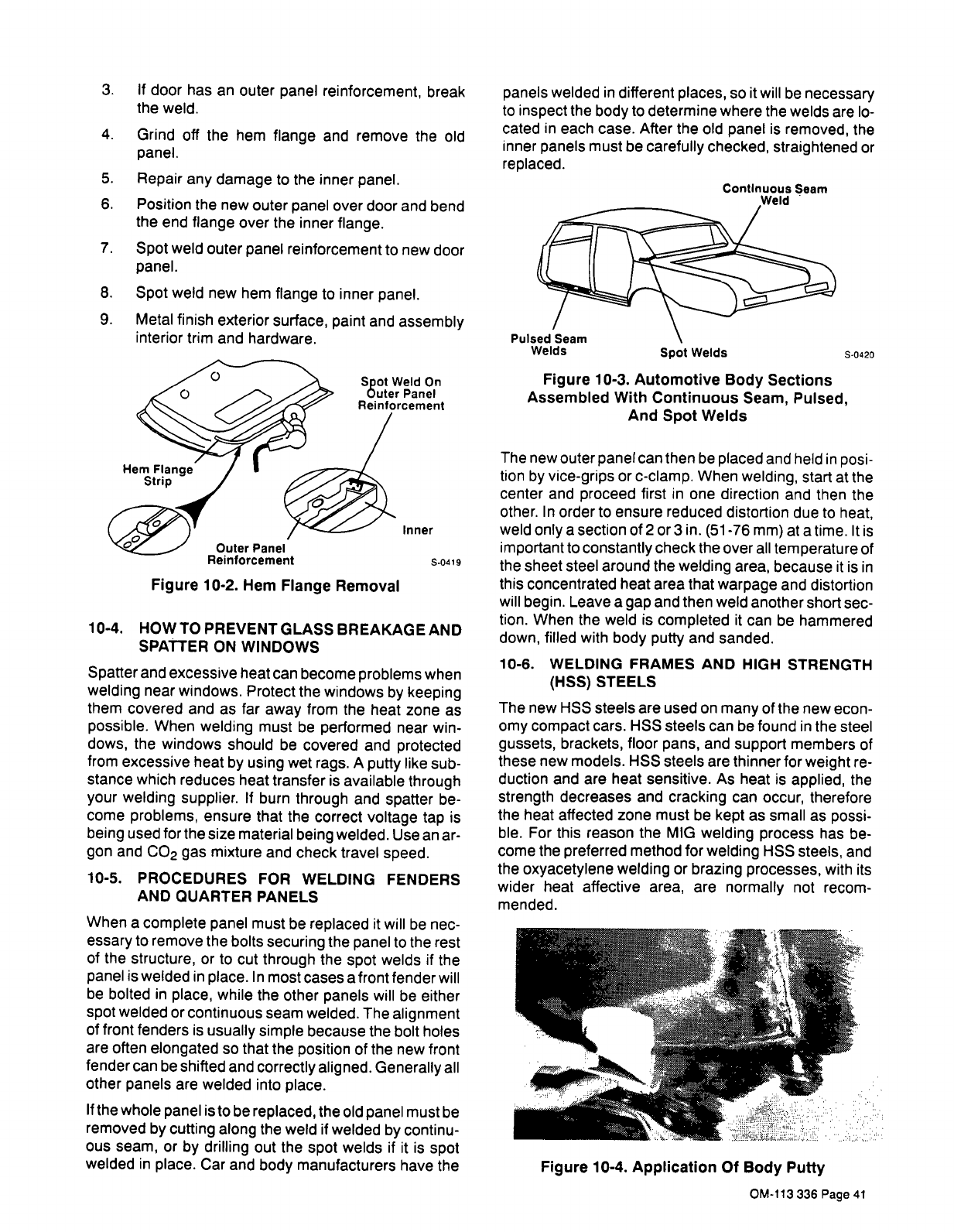

Figure

10-3.

Automotive

Body

Sections

Assembled

With

Continuous

Seam,

Pulsed,

And

Spot

Welds

S

-04

20

The

new

outer

panel

can

then

be

placed

and

held

in

posi

tion

by

vice-grips

or

c-clamp.

When

welding,

start

at

the

center

and

proceed

first

in

one

direction

and

then

the

other.

In

order

to

ensure

reduced

distortion

due

to

heat,

weld

only

a

section

of

2

or

3

in.

(51-76

mm)

at

a

time.

It

is

important

to

constantly

check

the

over

all

temperature

of

the

sheet

steel

around

the

welding

area,

because

it

is

in

this

concentrated

heat

area

that

warpage

and

distortion

will

begin.

Leave

a

gap

and

then

weld

another

short

sec

tion.

When

the

weld

is

completed

it

can

be

hammered

down,

filled

with

body

putty

and

sanded.

10-6.

WELDING

FRAMES

AND

HIGH

STRENGTH

(HSS)

STEELS

The

new

HSS

steels

are

used

on

many

of

the

new

econ

omy

compact

cars.

HSS

steels

can

be

found

in

the

steel

gussets,

brackets,

floor

pans,

and

support

members

of

these

new

models.

HSS

steels

are

thinner

for

weight

re

duction

and

are

heat

sensitive.

As

heat

is

applied,

the

strength

decreases

and

cracking

can

occur,

therefore

the

heat

affected

zone

must

be

kept

as

small

as

possi

ble.

For

this

reason

the

MIG

welding

process

has

be

come

the

preferred

method

for

welding

HSS

steels,

and

the

oxyacetylene

welding

or

brazing

processes,

with

its

wider

heat

affective

area,

are

normally

not

recom

mended.

8.

9.

Continuous

Seam

Weld

Pulsed

Seam

Welds

Spot

Weld

On

Outer

Panel

Reinforcement

Spot

Welds

Inner

Figure

10-2.

Hem

Flange

Removal

S

.04

19

Figure

10-4.

Application

Of

Body

Putty

OM-113

336

Page

41