882.00207.00 Chapter 2: Functional Description 19 of 102

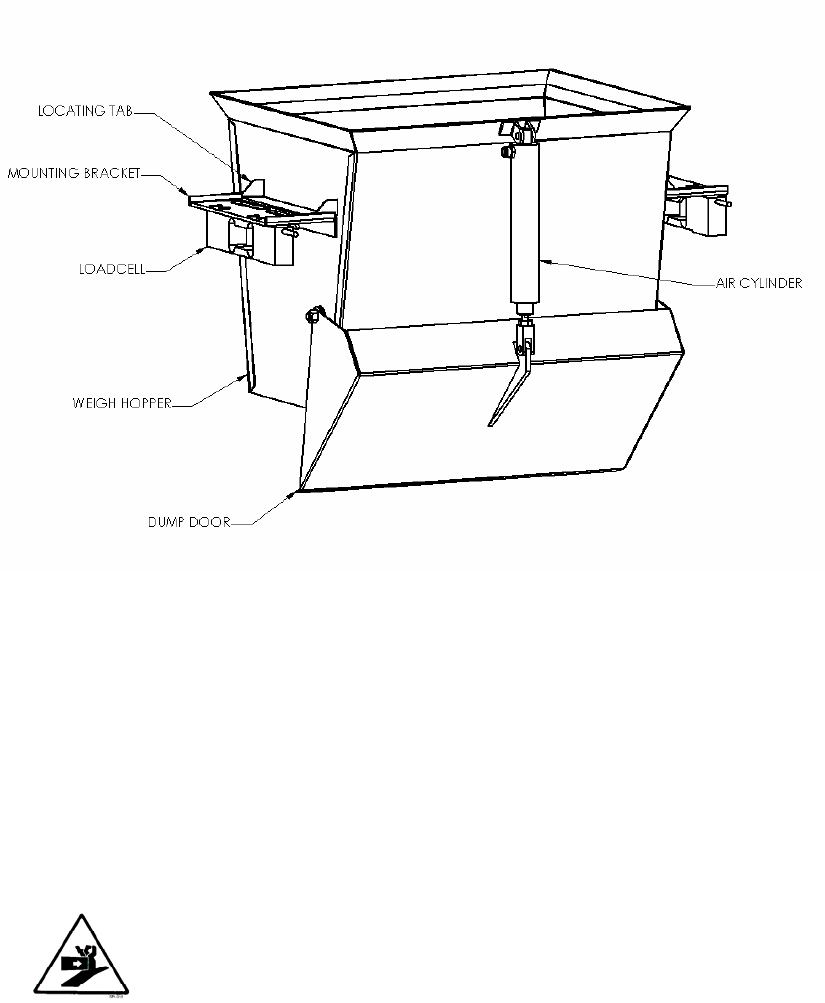

Figure 7: Typical Weigh Hopper Assembly

The weigh hopper dump door holds the material until it is dumped into the mixing section. The

cylinder is actuated by a solenoid in the valve stack on the side of the blender.

In looking at the pneumatic circuit, you can see that the air regulator controls the flow of air to the

valve stack. When the weigh hopper discharge cylinder solenoid valve is not electrically energized,

it will provide air pressure to the air cylinder and hold the shaft in an extended position, holding the

dump valve closed.

When the air cylinder is actuated, the air pressure to the dump valve will be removed, causing it to

open.

The air cylinder on the weigh hopper includes a spring return to allow the cylinder to retract in the

absence of air pressure on the cylinder. This will cause the dump valve to open.

Caution! The pneumatic system used on the Slide Gate blender, like all pneumatic systems,

is highly sensitive to oily, dirty, wet or contaminated air. If oil, dirt, water, or any

other air-borne contaminates enter the system, the components could be damaged

and injury to the operator could result. A proper air supply must be supplied to the

blender.

When the safety circuit is disabled, the air pressure to the cylinder will drop off by shutting off all

the air supply to the valve stack with the pilot operated master air valve. This will also cause the

weigh hopper discharge door to open.